Epoxy compound and cationic polymer and their preparation method

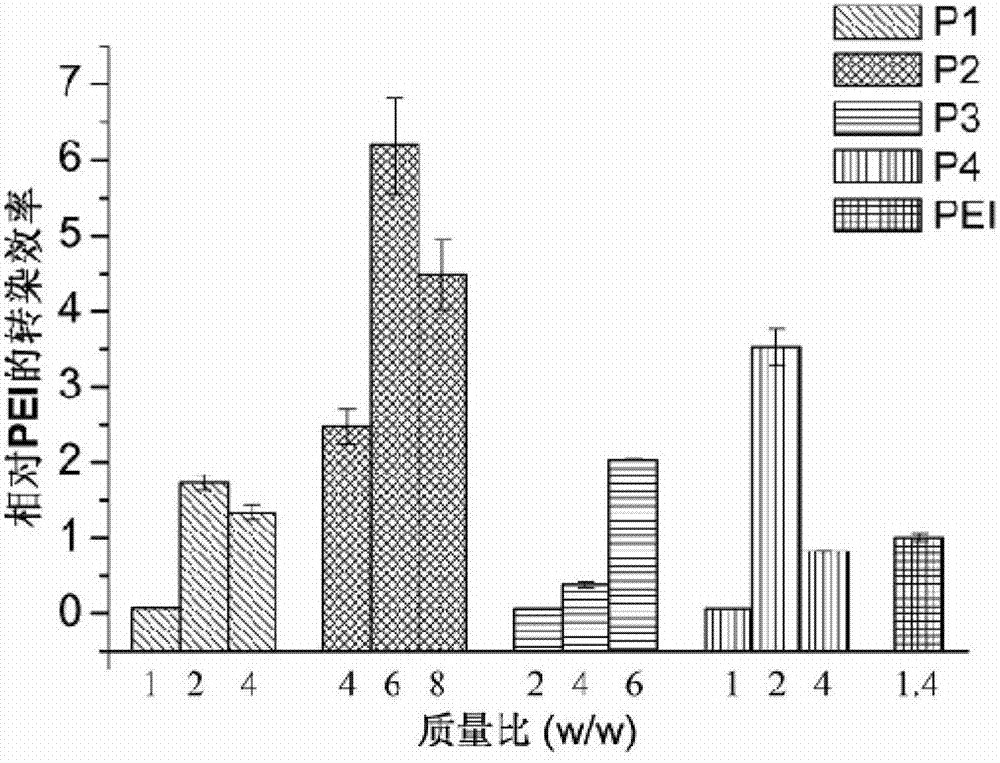

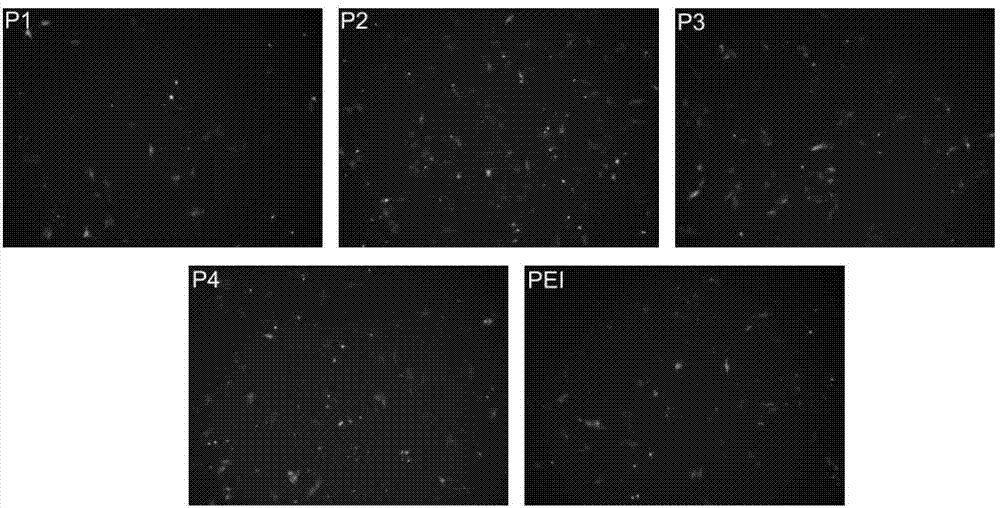

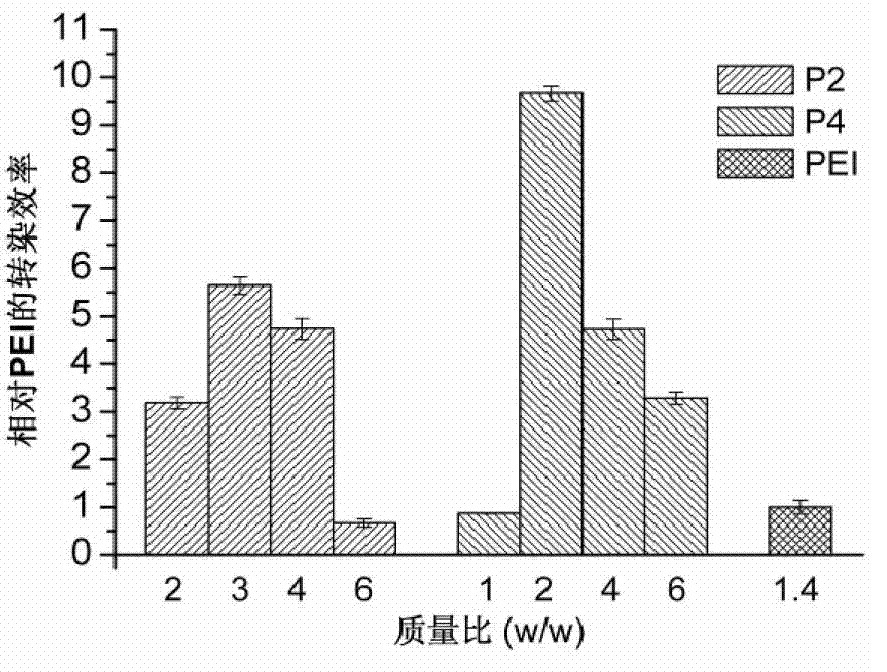

A technology of cationic polymers and epoxy compounds, applied in the direction of organic chemistry, can solve the problems of limited application, high cytotoxicity, and reduced transfection efficiency, and achieve the effects of improving stability, reducing cytotoxicity, and high transfection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Add 0.02mmol (2.96g) of N,N'-dihydroxyethylethylenediamine and 0.048mmol (4.84g) of triethylamine into 100mL of dichloromethane, and stir in an ice-water bath until they are completely dissolved. Then, 0.044 mmol (8.72 g) of di-tert-butyl dicarbonate completely dissolved in 50 mL of dichloromethane was added dropwise at a speed of 3 s / drop. Ester recrystallization and column separation yielded 3.56 g of a pure white intermediate compound N,N'-2Boc-N,N'-dihydroxyethylethylenediamine with the following structure, with a yield of 51%:

[0054]

[0055] 1 H NMR (400 MHz, DMSO, TMS): δ = 1.39 (s, 18H, -Boc), 3.18 (m, J = 4 Hz, 4H, -CH 2 CH 2 OH), 3.29 (m, J = 12Hz, 4H, -CH 2 CH 2 -), 3.45 (m, J = 4 Hz, 4H, -CH 2 CH 2 OH), 4.66 (S,2H,-OH).

[0056] 13 C NMR (DMSO, 100 MHz): δ 28.02, 49.93, 55.99, 58.95, 78.38, 154.55.

[0057] HR-MS (ESI): Calcd for: C 16 h 32 N 2 o 6 : 371.2158[M+Na] + ; Found: 371.2156[M+Na] + ;

[0058] (2) At room temperature, mix 1...

Embodiment 2

[0064] (1) Add 0.02mmol (2.96g) of N,N'-dihydroxyethylethylenediamine and 0.042mmol (4.25g) of triethylamine into 100mL of dichloromethane, and stir in an ice-water bath until they are completely dissolved. Then, 0.042 mmol (9.16 g) of di-tert-butyl dicarbonate completely dissolved in 50 mL of dichloromethane was added dropwise at a rate of 2 s / drop. Ester recrystallization and column separation yielded 3.22 g of pure white intermediate compound N,N'-2Boc-N,N'-dihydroxyethylethylenediamine with a yield of 46%:

[0065]

[0066] (2) At room temperature, mix 6.3 mmol (2.2g) N,N'-2Boc-N,N'-dihydroxyethylethylenediamine, 37.9mmol (3.5g) epichlorohydrin, 37.9mmol (1.5g ) Sodium hydroxide, 0.31mmol (100mg) tetrabutylammonium bromide, 30ml dichloromethane and 1.1 mmol (20mg) water were stirred and mixed together, after the solid matter was basically dissolved, heated to 40°C for 6h, cooled to room temperature, Suction filtration, then wash the filter cake with dichloromethane and...

Embodiment 3

[0069](1) Add 0.02mmol (2.96g) N,N'-dihydroxyethylethylenediamine and 0.05mmol (5.05g) triethylamine into 100mL dichloromethane, and stir in an ice-water bath until they are completely dissolved, Then, 0.05 mmol (10.91 g) of di-tert-butyl dicarbonate completely dissolved in 50 mL of dichloromethane was added dropwise at a speed of 4 s / drop. Ester recrystallization and column separation yielded 3.99 g of pure white intermediate compound N,N'-2Boc-N,N'-dihydroxyethylethylenediamine with a yield of 57%:

[0070]

[0071] (2) At room temperature, mix 5 mmol (1.7g) N,N'-2Boc-N,N'-dihydroxyethylethylenediamine, 50mmol (4.6g) epichlorohydrin, 50mmol (2.0g) hydrogen Sodium oxide, 0.5mmol (160mg) tetrabutylammonium bromide, 20ml dichloromethane and 1mmol (18mg) water were stirred and mixed together, after the solid matter was basically dissolved, heated to 45°C for 8 hours, cooled to room temperature, and suction filtered. The filter cake was washed with dichloromethane and suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com