Method and device for measuring position and temperature of combustion zone in sinter bed

A measurement device and layer combustion technology, applied in the direction of measurement devices, instruments, etc., to achieve the effects of high precision structure, convenient operation, and simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

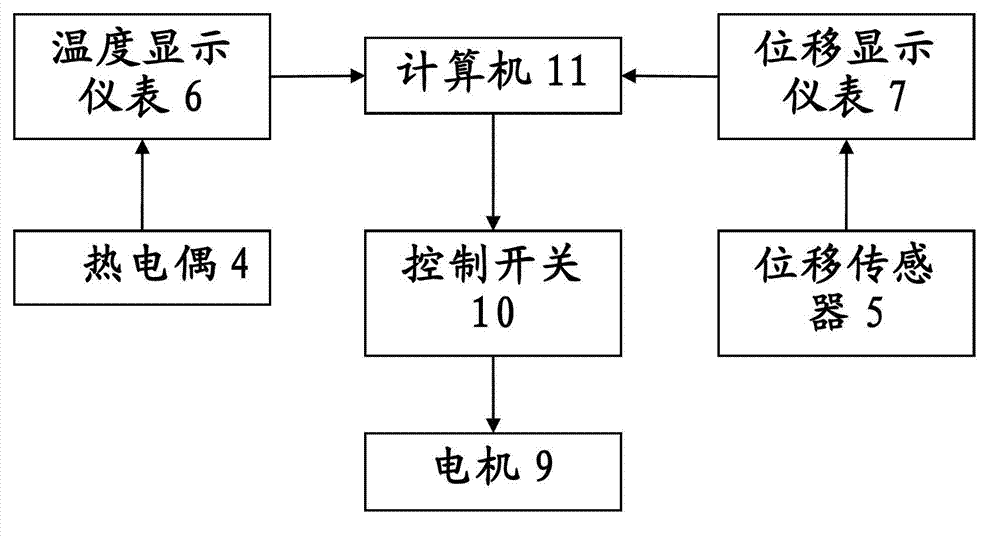

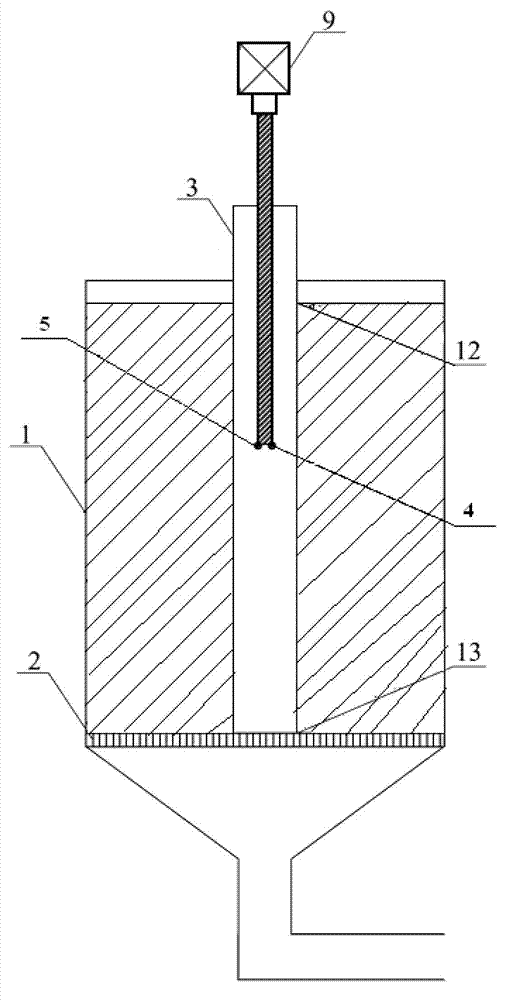

[0020] A method for measuring the temperature and position of the combustion zone of the sintered bed provided by the present invention comprises the following steps:

[0021] S1. Before starting the sintering process, initialize the measuring device;

[0022] S2. When the sintering starts, the measuring device starts to work at the same time, and returns the measured temperature value and displacement in real time;

[0023] S3. The control computer compares the recorded real-time temperature parameters, and when an extreme value occurs, it sends a control command to change the state of the control switch 10, and records the displacement parameter D at the same time i , running time t i and the peak temperature T i ; Wherein, i is the number of times that the state of the control switch 10 changes;

[0024] S4. The operation of the above step S3 is repeated cyclically until the sintering is completed.

[0025] The method of the present invention will be further described b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com