water pump gearbox

A gear box and water pump technology, applied in the direction of gear transmission, belt/chain/gear, transmission box, etc., can solve the problems of accelerating the wear of related parts of the gearbox, increasing the production cost of the whole set of units, reducing the life cycle of the gearbox, etc. The effect of ensuring the connection accuracy, compact overall structure and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

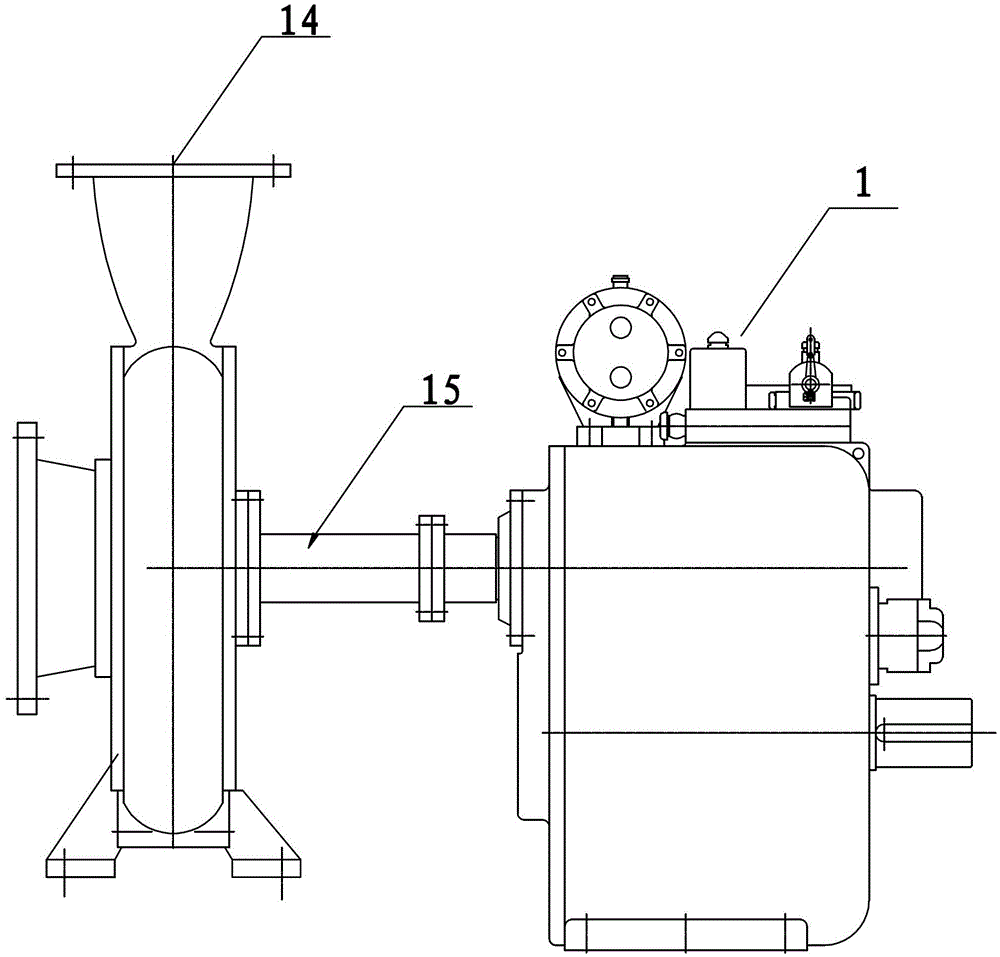

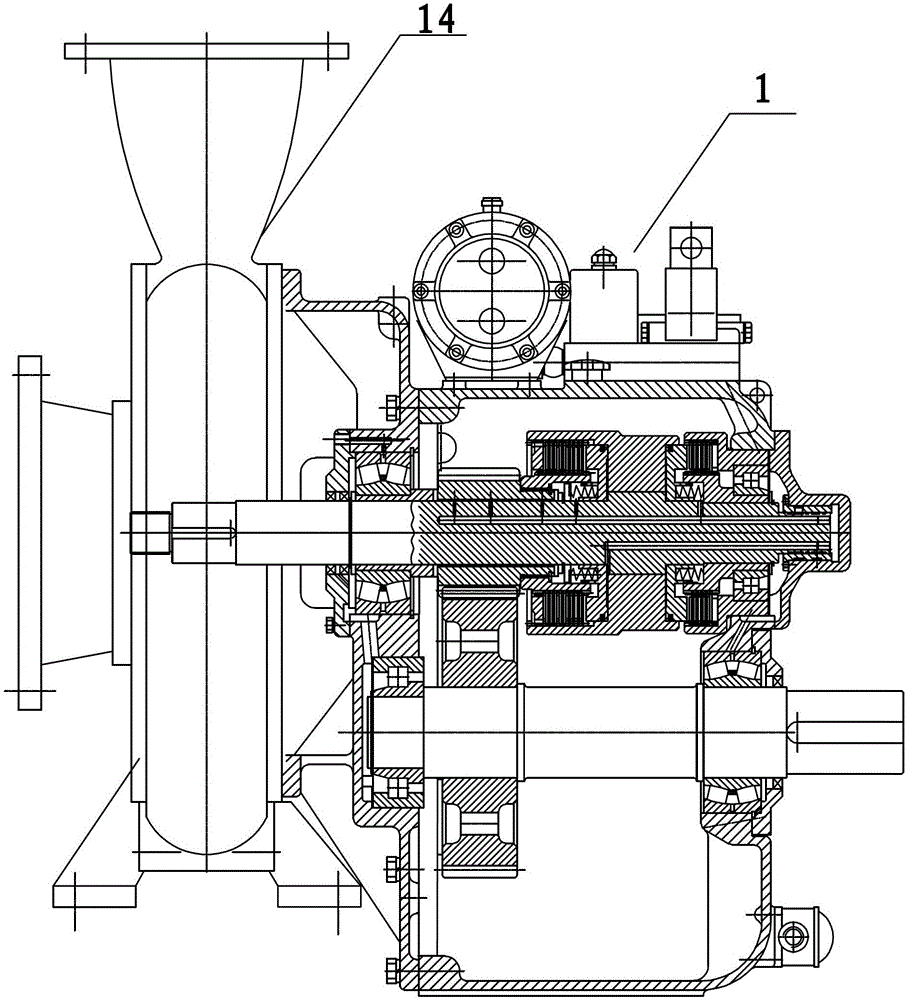

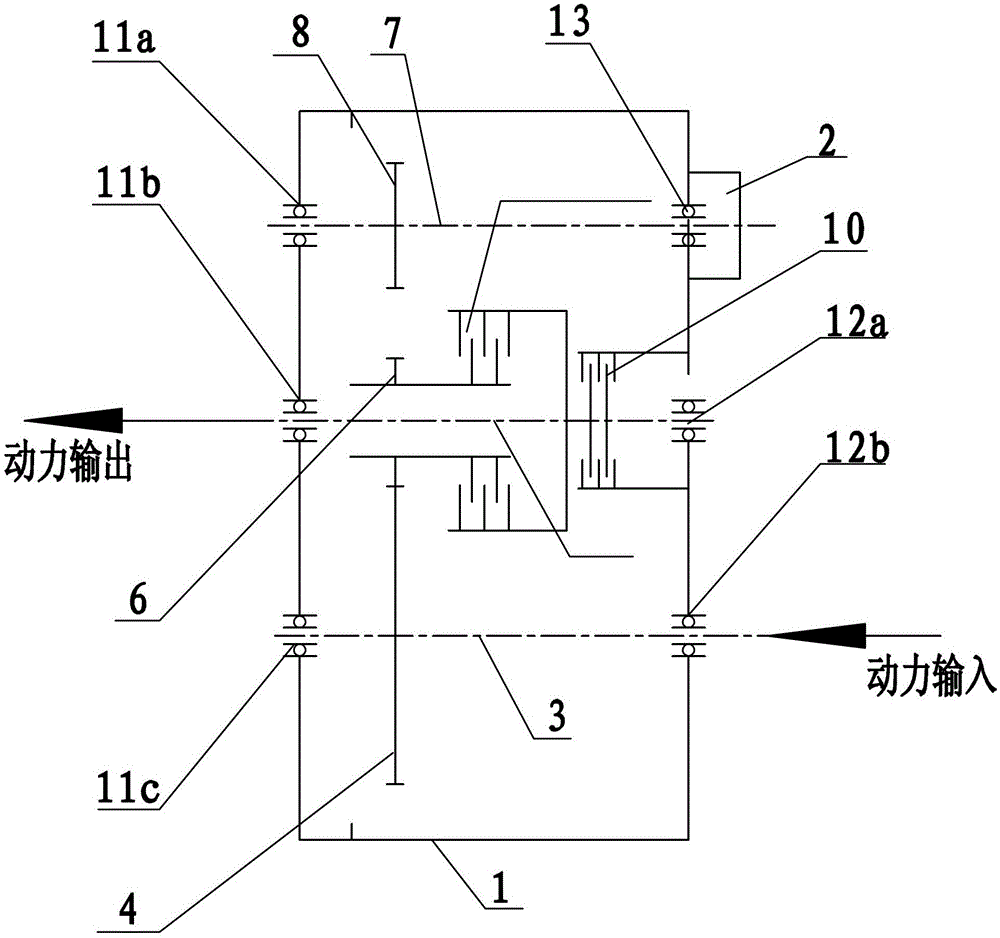

[0022] The water pump gear box of the present invention includes a box body 1, an oil pump 2 is arranged above the box body 1, and along the longitudinal section direction of the box body 1, an input shaft 3, an input gear 4, an output shaft 5, and an output gear 6 are sequentially installed in the box body 1 , Transmission shaft 7 and transmission gear 8, one end of input shaft 3 is connected with power shaft, and input gear 4 is installed on the other end; Transmission gear 8 is installed on transmission shaft 7, transmission gear 8 meshes with input gear 4; Output shaft is installed with The output gear and the input gear 4 mesh with the transmission gear 8 and the output gear 6 respectively; the casing 1 is connected with the water pump arranged in front of the casing 1 through the output shaft 5 , and the rear is connected with the power shaft through the input shaft 3 . Simultaneously, drive shaft 7 is also provided with main clutch 9 and brake clutch 10, and main clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com