Valve with articulated valve core

A hinged, spool technology, applied in the direction of valve operation/release device, valve lift, valve details, etc., can solve the problems of occupying the external space of the valve body, many parts of the transmission device, and shorten the life of the valve, etc., to achieve the opening angle Large size, low manufacturing cost, small opening and closing torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings, so as to better understand the purpose, features and advantages of the present invention. It should be understood that the embodiments shown in the drawings are not intended to limit the scope of the present invention, but only to illustrate the essence of the technical solutions of the present invention.

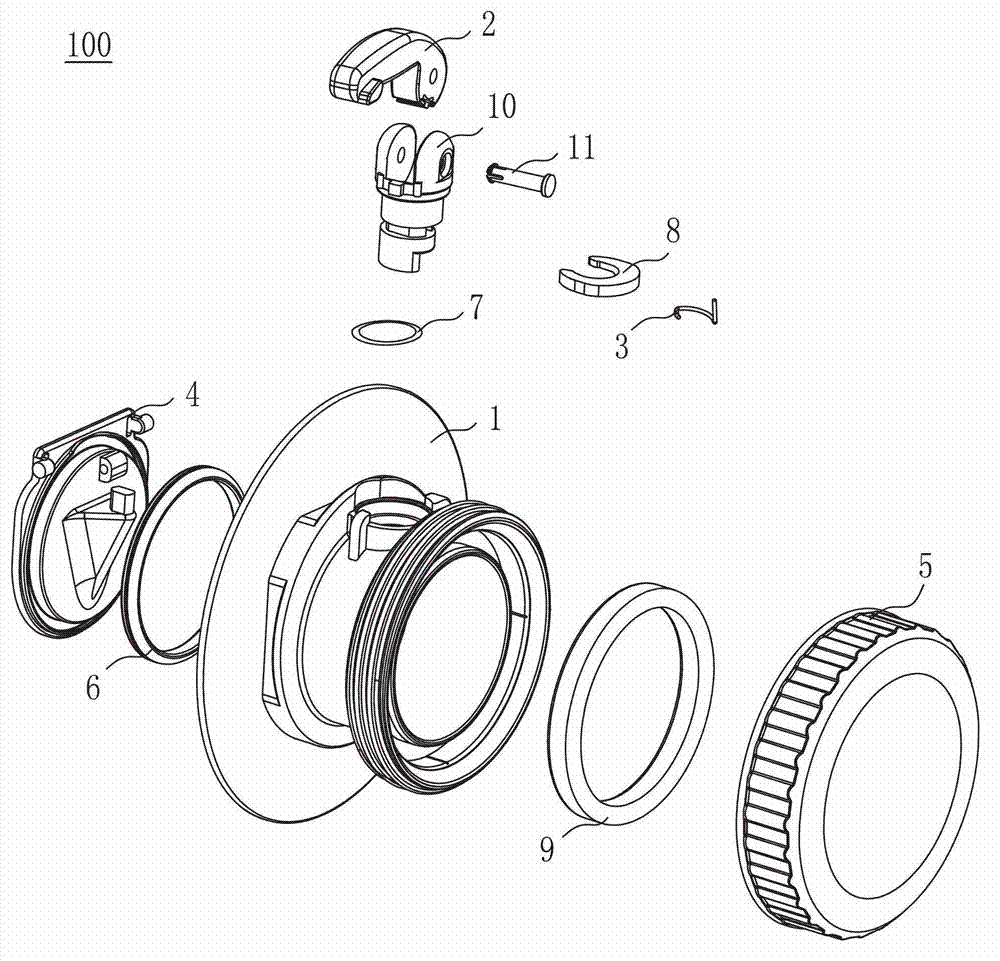

[0037] figure 1 An exploded perspective view of a first embodiment of a valve 100 with a hinged spool according to the invention is shown. like figure 1As shown, the valve 100 includes a valve body 1 , a handle 2 , a steel wire spring 3 , a valve core 4 , a valve cover 5 , sealing rings 6 , 7 and 9 , buckles 8 , a valve stem 10 , and a handle pin 11 . Wherein, the valve core 4 is connected to the valve body 1 through a hinge, and the hinge is composed of a hinge shaft provided on the valve core 4 and a hinge hole provided on the valve body 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com