Light-emitting diode (LED) street lamp

A technology for LED street lamps and housings, which is applied in the cooling/heating devices of lighting devices, outdoor lighting, sustainable buildings, etc., can solve the problems of fixed light distribution angle, inability to adjust differently, and difficulty in reaching the light spot standard. Improve the heat dissipation effect and ensure the effect of normal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

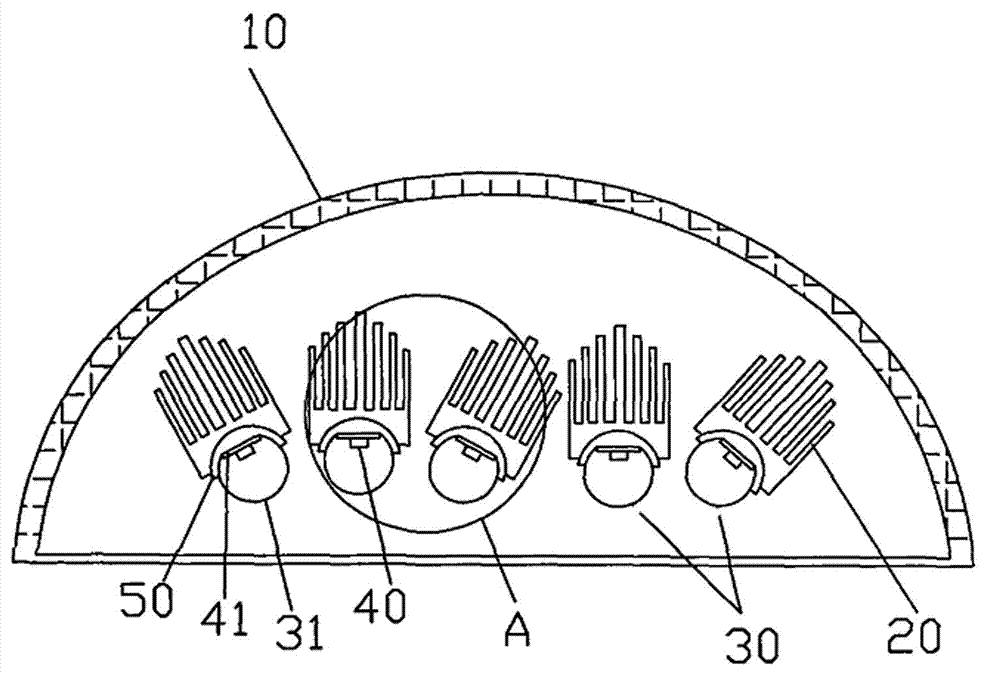

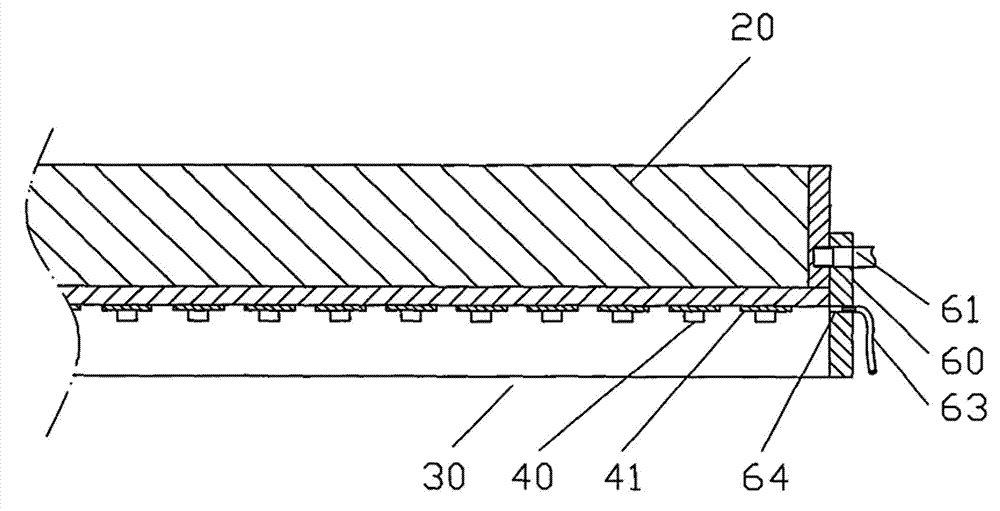

[0012] As shown in the drawings, an LED street lamp includes a housing 10, and also includes a plurality of LED street lamp units 30 with adjustable angles and independent power supply arranged in the housing. Each LED street lamp unit includes a driving power supply, a heat sink 20, The substrate 50 attached to the heat sink, the PCB board 41 arranged on the substrate 50, the LED lamp bead 40 and the transparent lampshade 31 arranged on the PCB board 41, the rotating shaft 61 of the LED street lamp unit is arranged on the housing and passed through the connecting sheet 60 Connected to heat sink 20. The transparent lampshade 31 can be made of plastic, and each LED street lamp unit can independently lead out a power line directly connected to the power grid. The heat sink 20 protrudes into multiple pieces like a palm to ensure heat dissipation.

[0013] During the working process, the LED street lamp unit may cause the lampshade to break due to thermal expansion and contraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com