Headlight projection module for a motor vehicle

A technology for projection modules and headlights, applied in the direction of headlights, vehicle parts, vehicle lighting systems, etc., can solve the problem of different circular cross-sections, and achieve a large design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

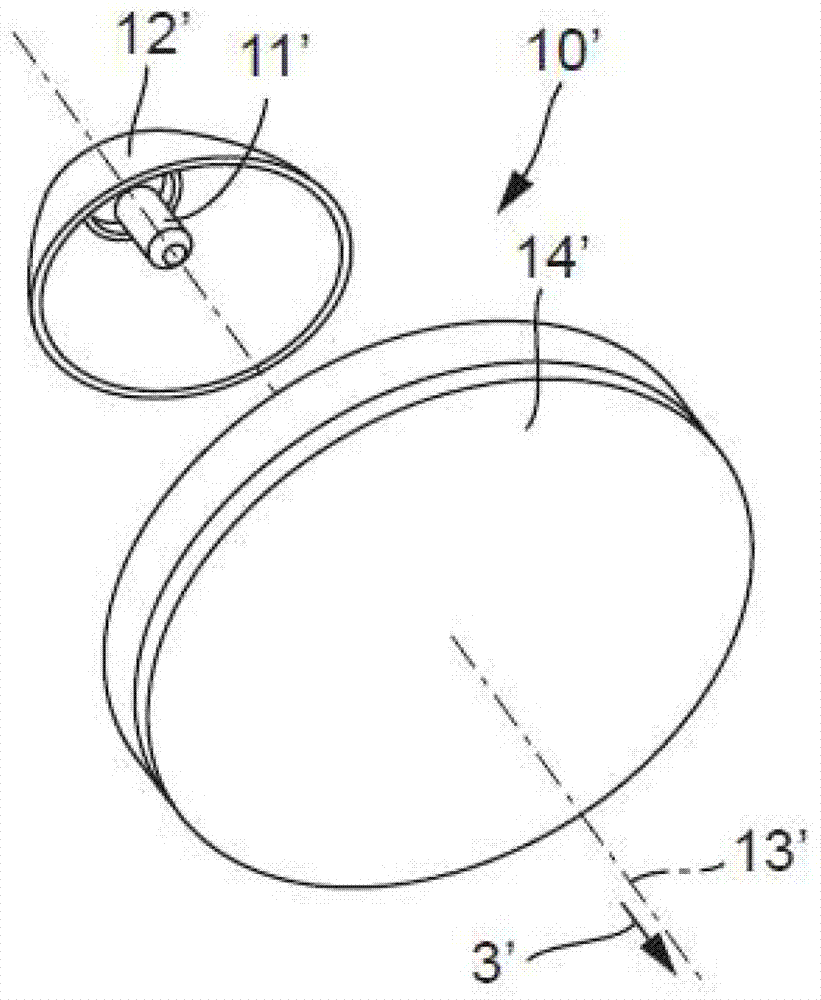

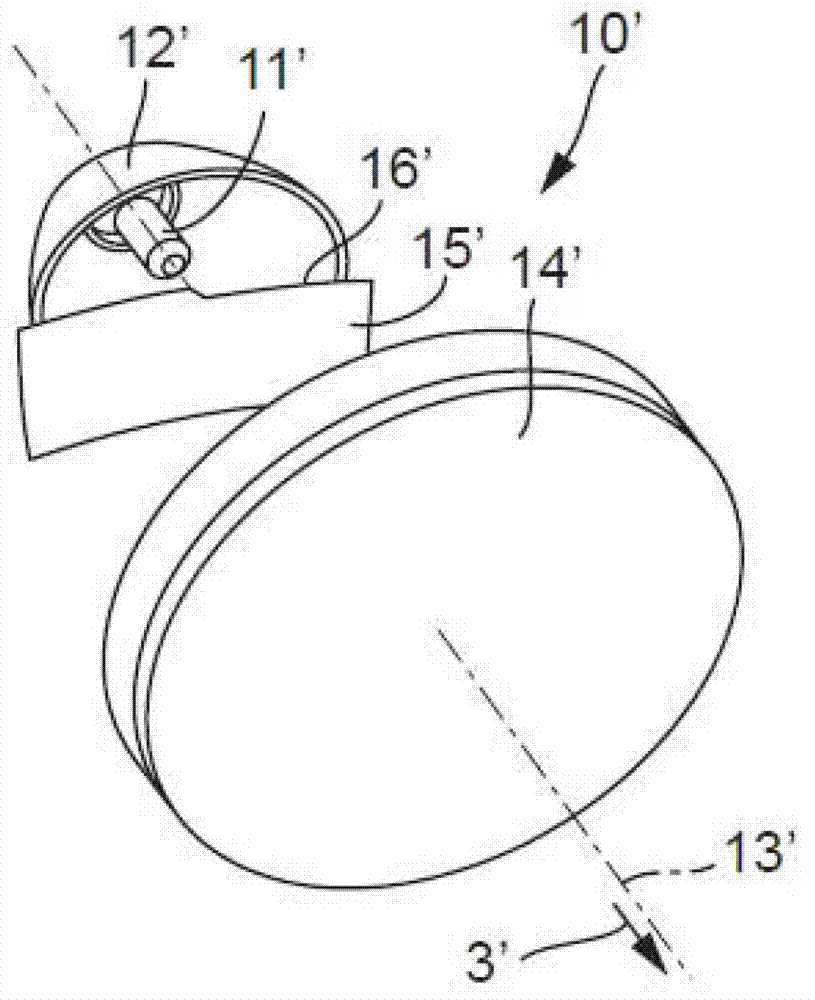

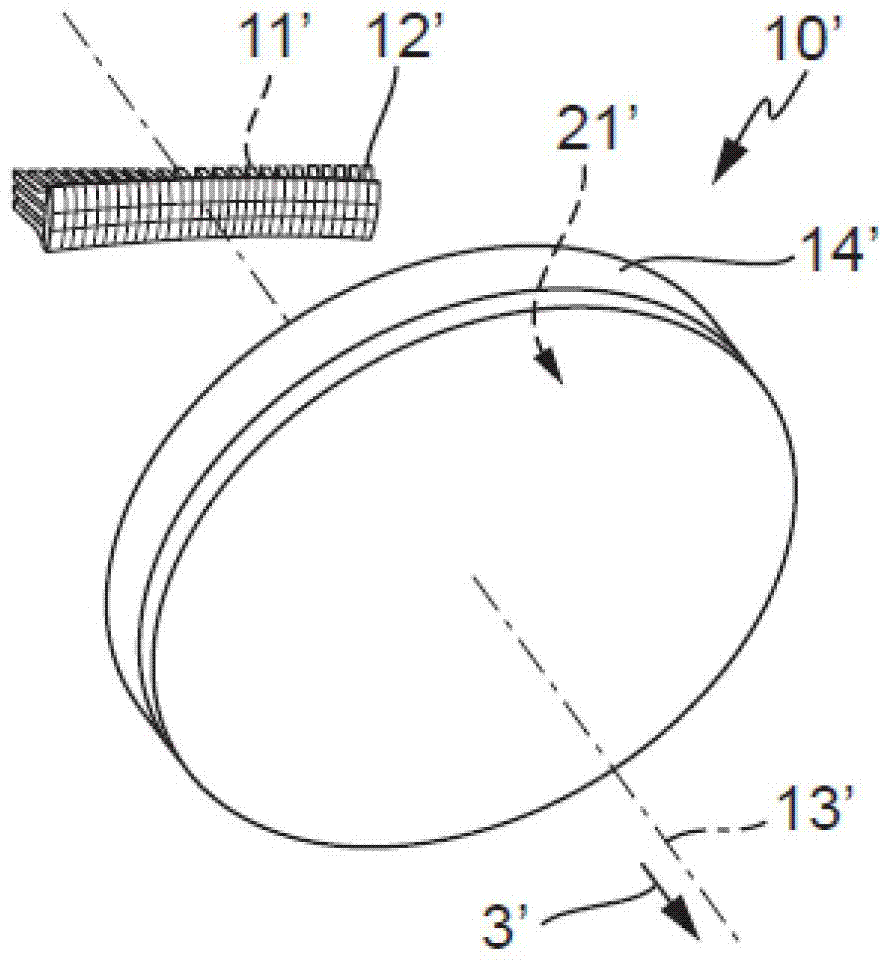

[0057] The invention relates to the field of motor vehicle headlights. exist Figure 19 Such a headlight is shown by way of example in , and is indicated as a whole by the reference numeral 1 . The headlight 1 contains a headlight housing 2 which is preferably made of plastic. In the light exit direction 3 , the housing 2 has a light exit opening 4 which is closed by a transparent cover 5 , preferably made of glass or transparent plastic. Of course, the housing 2 and the cover plate 5 can also be made of other materials different from the above materials. The cover plate 5 can have optically active elements, such as prisms or cylindrical lenses, in order to spread the penetrating light in the horizontal and / or vertical direction. However, it is also conceivable that the cover plate 5 is designed as a so-called clear disk without optically active elements.

[0058] Arranged within the headlight housing 2 is at least one projection module 10 according to the invention, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com