Light guide film with multi-faceted light input edge

A light guide film and edge technology, applied in the field of light guide film, can solve the problem of reducing the efficiency of edge jagged features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

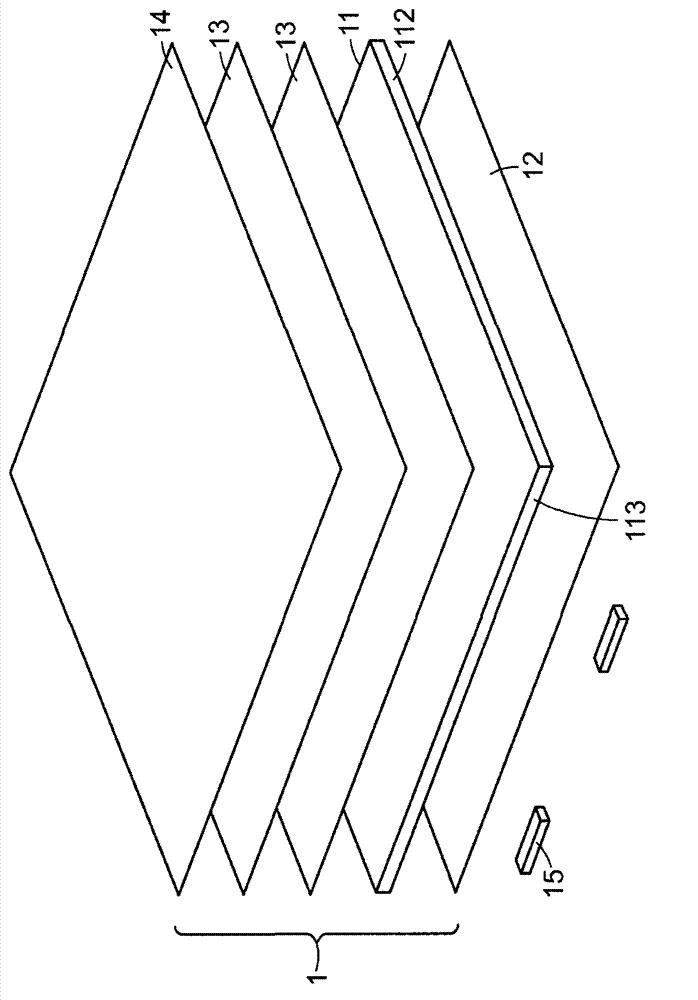

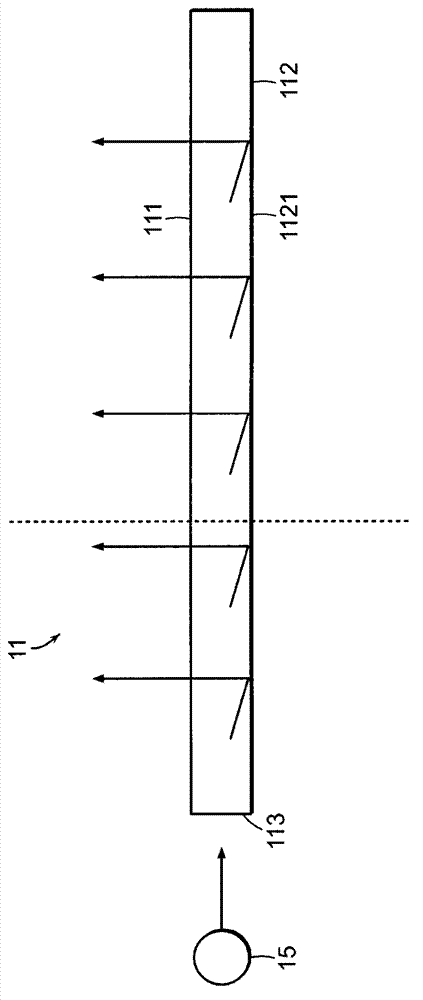

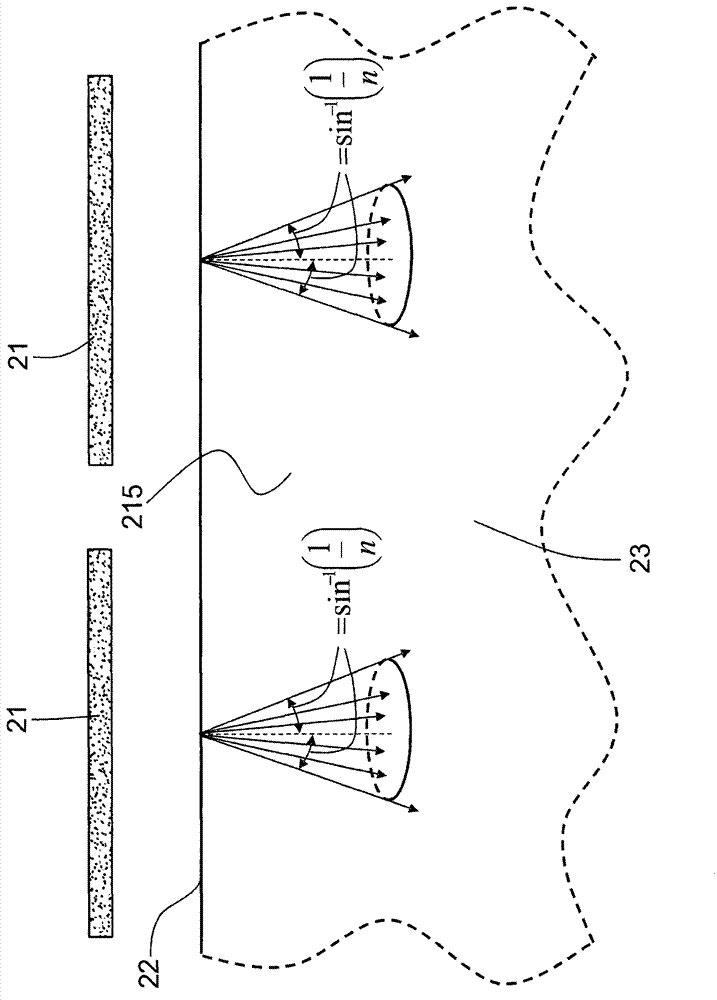

[0047] Referring now to the accompanying drawings, the attached Figure 5A A light directing film 33 of the present invention is shown having a light input edge with a plurality of multi-faceted features 32 . attached Figure 5B An enlarged top view of the invention is shown. The light emitted by the point light source 31 is incident on the multi-faceted feature 32 . Each light source 31 covers at least one faceted feature.

[0048] Each multi-faceted feature includes a feature top and a feature recess. The feature top includes a flat surface. In addition, each multi-faced feature further includes at least two sets of ramps between the feature top and adjacent feature recesses. Each set of ramps includes two ramps on opposite sides of the top of the feature. Each flat or sloped surface has a planar surface area. The slope angle of each ramp tapers from the feature recess to the feature top. The set of ramps near the recess of the feature has a greater angle of inclinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com