Electronic screen method full-automatic motor vehicle headlight detector and detecting method

A detector and motor vehicle technology, applied in the direction of testing the alignment of automobile headlights, testing optical performance, etc., can solve the problem of not being able to receive in a large area, and achieve the effect of simple operation and stable and reliable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

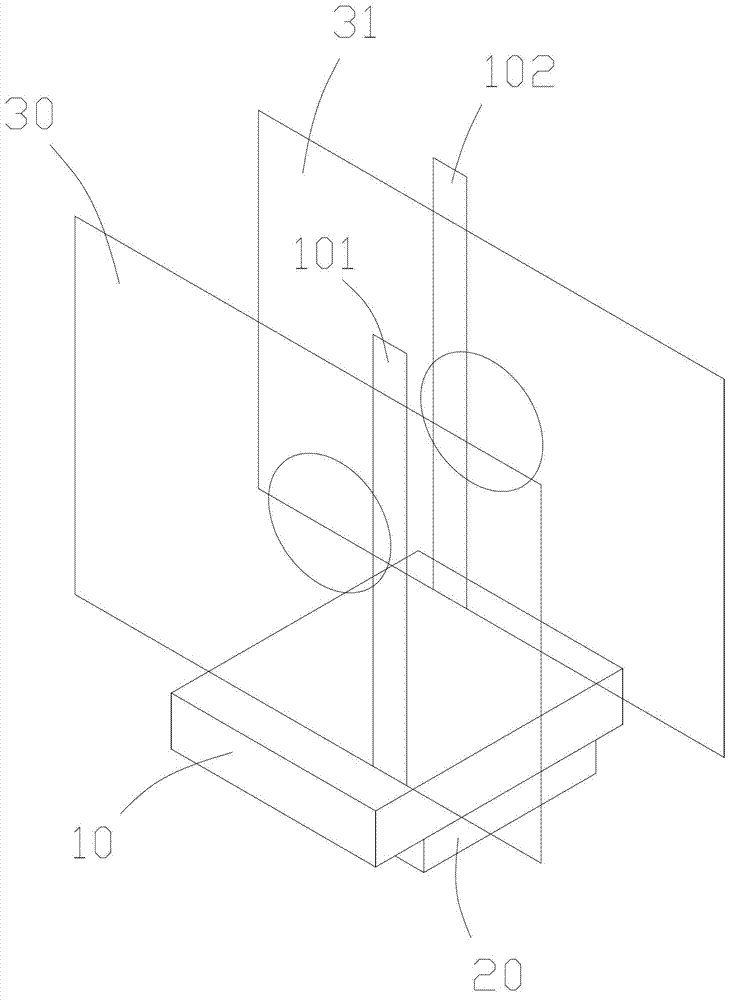

[0032] Such as figure 1 As shown, a fully automatic motor vehicle headlight tester with electronic screen method includes a tester 10. The bottom of the tester 10 is provided with a walking mechanism 20 that can drive the tester 10 to move in the horizontal direction. Before the simulation, the electronic screen wall 30, the detector 10 rear is provided with the simulation rear electronic screen wall 31, the detector 10 is perpendicular to the traveling direction of the measured motor vehicle, by drawing on the simulation front electronic screen wall 30 and the simulation rear electronic screen wall 31 The method of screen crosshairs is used to determine the beam deviation of the motor vehicle headlights, and the light intensity and light spots ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com