Method for testing biaxial strength of thermal barrier coating

A technology of thermal barrier coating and strength testing, applied in the direction of applying stable tension/compression to test the strength of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

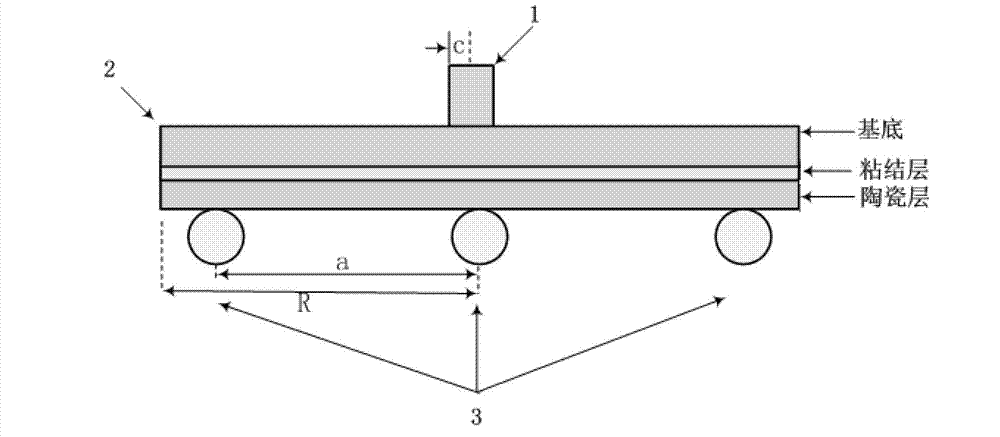

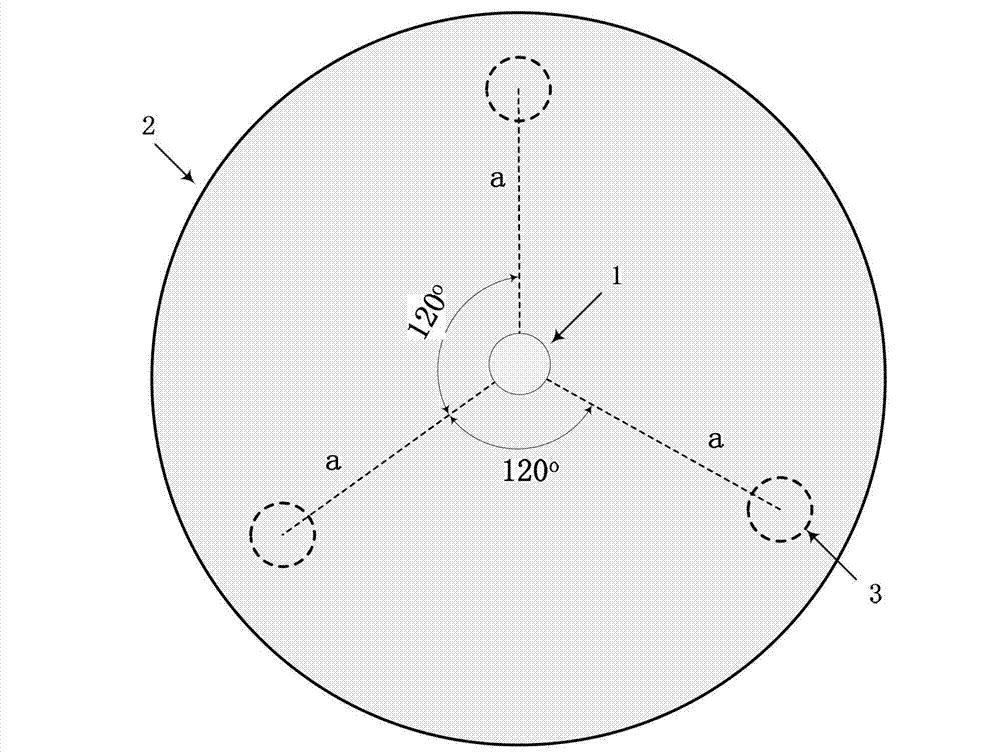

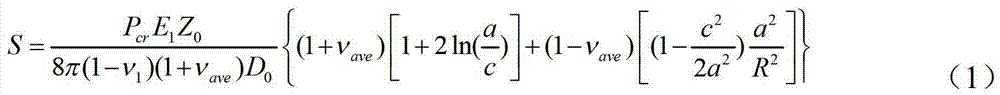

[0034] Such as figure 1 with figure 2 As shown, a method for testing the biaxial strength of a thermal barrier coating of the present invention comprises the following steps:

[0035] Step 1: First measure the thickness t and radius R of each layer of the thermal barrier coating disk specimen 2, and obtain the elastic modulus E and Poisson's ratio ν of each layer of material at the same time; then place the three specimen support parts 3 on The periphery of one side of the ceramic layer at the bottom of the thermal barrier coating disc test piece 2, and the support parts 3 of the test piece are symmetrically distributed along the symmetrical center of the thermal barrier coating disc test piece 2, and the measuring point to the thermal barrier coating disc test piece The distance a between the center of symmetry of the piece 2; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com