A pressure precision adjustment device

A precision adjustment and pressure technology, applied in the direction of electric fluid pressure control, liquid variable capacity machinery, pump control, etc., to achieve the effect of improving anti-interference ability, high-precision pressure stable adjustment, and low consistency requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

[0034] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

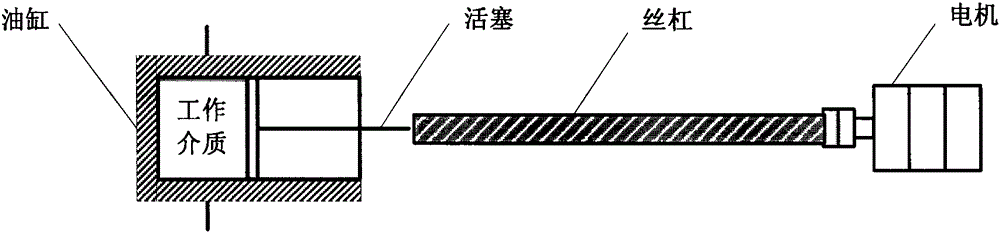

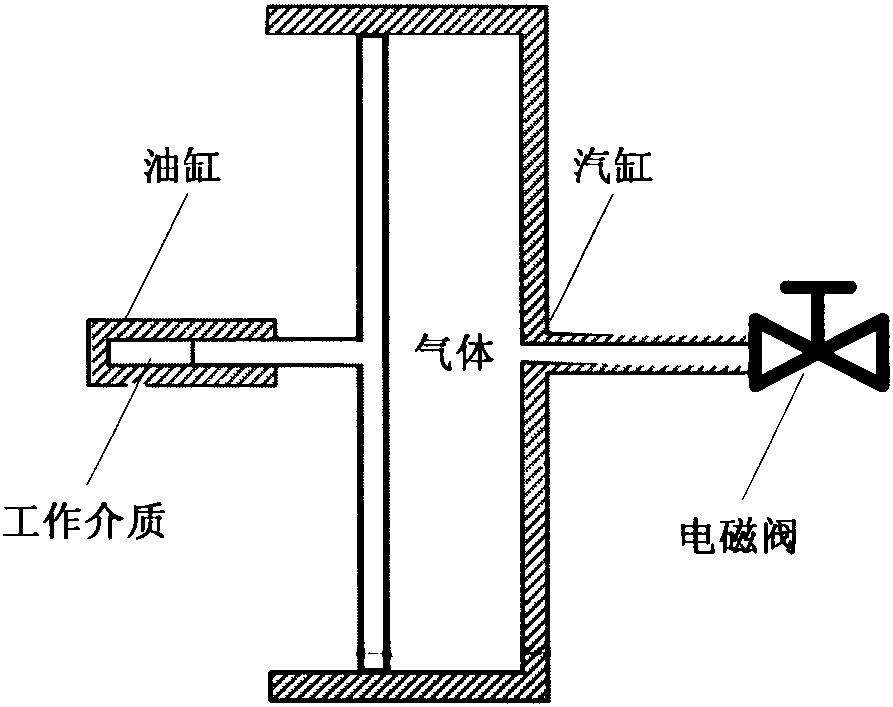

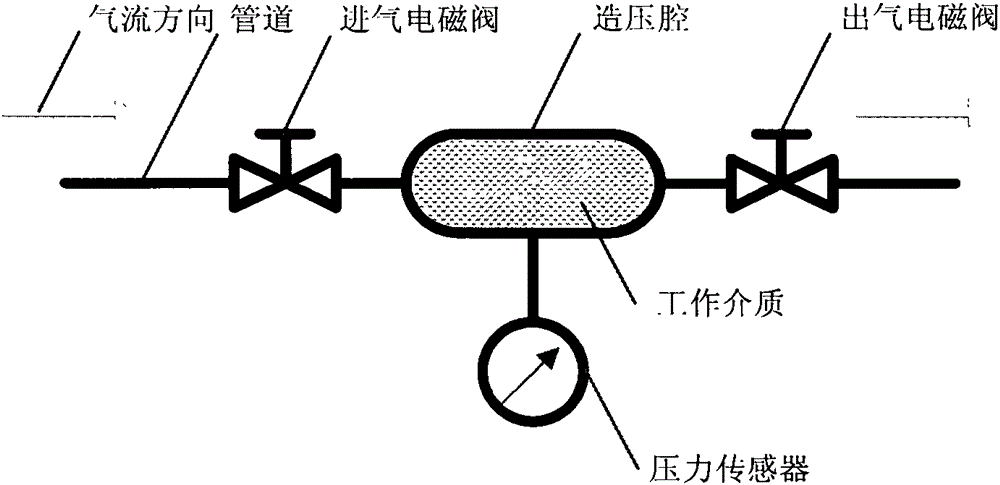

[0035] Such as figure 2 As shown, the embodiment of the present invention provides a pressure precision adjustment device, which can be seen from the figure. The devices include:

[0036] An actuator (1), which includes an elastic sensitive element (3), an elastic deformation conversion device (4), a stepper motor and a driver (5), a coarse pressure adjustment mechanism (6) and a pressure chamber (11), the The pressure cavity (11) communicates with the cavity of the elastic sensitive element (3), and the internal pressure of the cavity is equal;

[0037] A control mechanism (2), which includes a processor (7), a touch screen (8), an analog-to-digital converter (9), a pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com