Pressure stabilization and adjustment design for constant-pressure reaction vessels

A reaction vessel and pressure stabilization technology, which is applied in the direction of instruments, fluid pressure control, control/regulation systems, etc., can solve the problems of complex structure, poor constant pressure buffer capacity, pressure fluctuation, etc., and achieve high safety performance and maintain pressure stability , the effect of small pressure fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] specific implementation plan

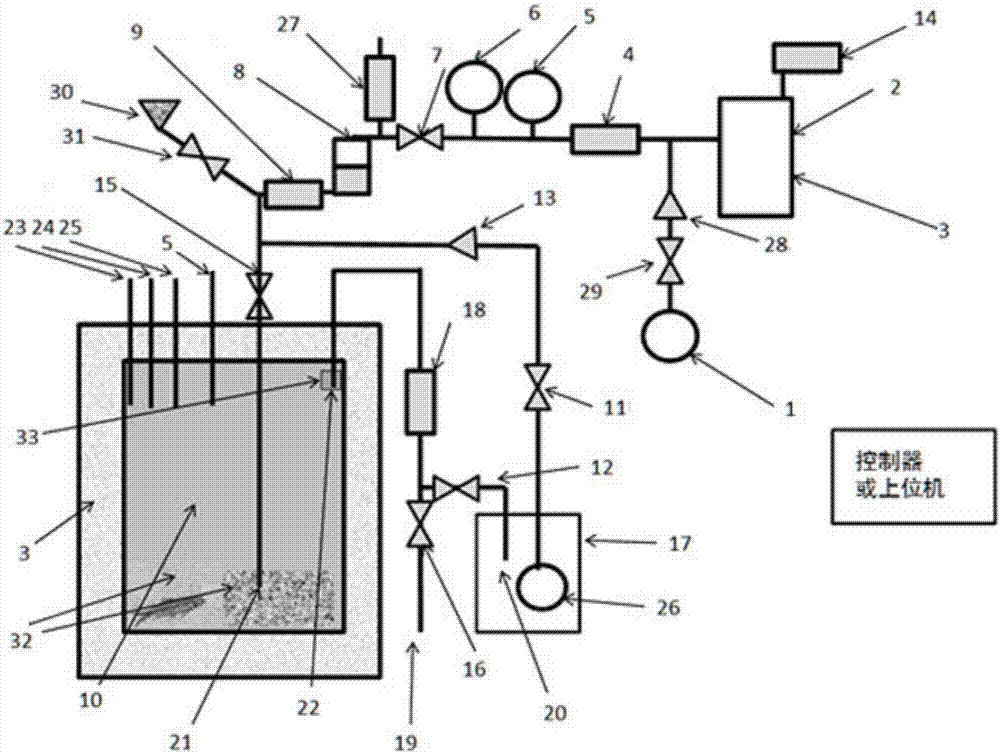

[0041] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the drawings and embodiments. Such as figure 1 As shown, the constant pressure reaction vessel includes a high-pressure air pump connected in sequence, a constant temperature and high pressure gas tank, a high pressure gas tank constant temperature system, electric regulating valves I, II and VIII, pressure sensors, pressure gauges, solenoid valves I and II, accumulators , Solenoid valve and reactor, the reactor can be equipped with various required sensors and safety devices, such as pressure sensor, temperature sensor, safety valve and pressure relief valve, reactor constant temperature system, etc.

[0042] When the constant pressure reaction vessel is working, the volume change caused by the change of liquid or solid-liquid system in the reaction vessel due to physical or chemical process will cause...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com