A kind of nickel-based positive electrode material and its preparation method and battery

A positive electrode material, nickel-based technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as uneven distribution of elements, and achieve the effects of improved cycle performance, small particle size, and shortened diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

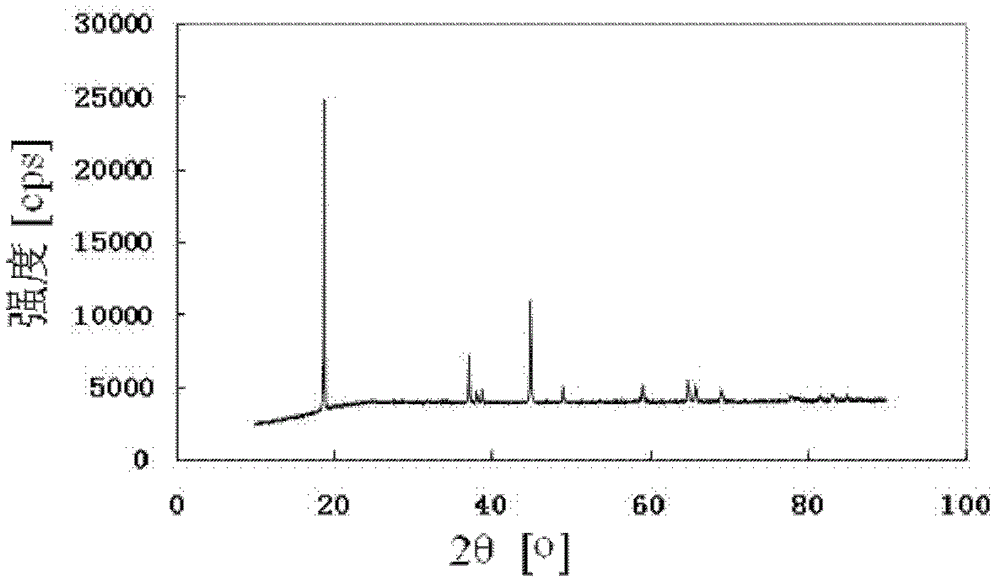

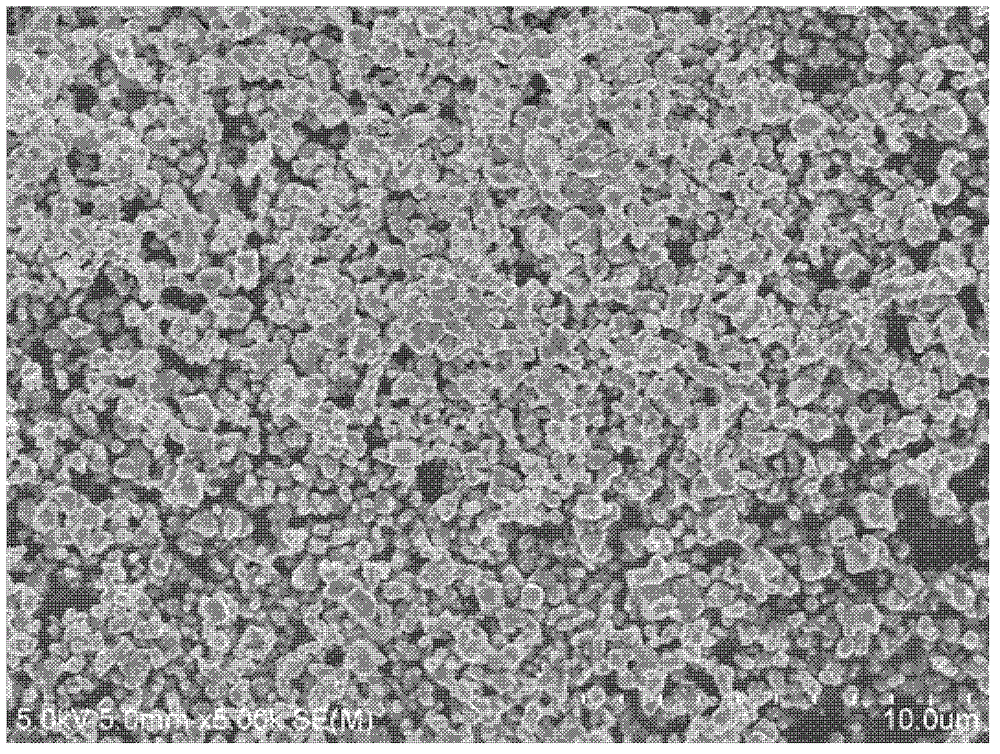

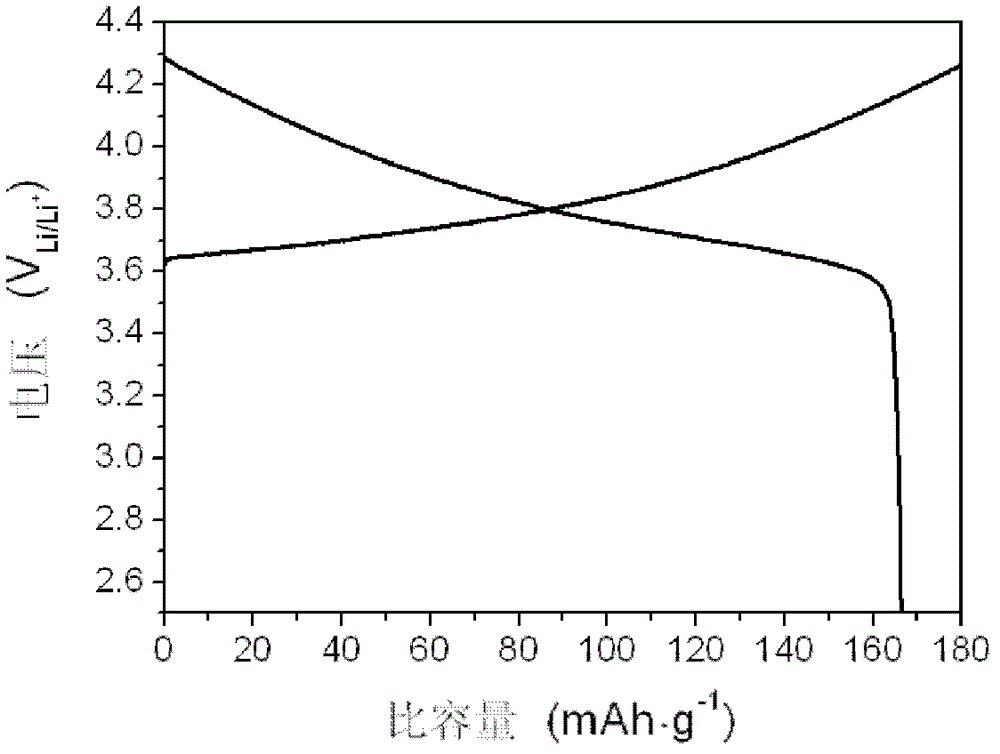

specific Embodiment 1

[0047] Preparation of LiNi by Lithium Carbonate, Manganese Carbonate, Cobalt Tetroxide and Nickel Oxide as Main Raw Materials 0.5 co 0.28 mn 0.16 Si 0.03 Zr 0.03 o 1.98 f 0.04 . 363.2g of lithium carbonate, 10.6g of lithium fluoride, 382.1g of nickel oxide, 230.0g of cobalt tetroxide, 32.9g of zirconia, 18.4g of silicon dioxide, 188.2g of manganese carbonate, mixed with 6000ml of absolute ethanol, and placed in a coarse grinding machine Roughly grind for 200 minutes, move the slurry into a fine grinder, grind for 200 minutes, take out the material from the fine grinder, and dry at 80°C. The powder obtained after drying was calcined at 900°C for 12 hours, and then cooled with the furnace.

specific Embodiment 2

[0048] Preparation of LiNi by Lithium Carbonate, Manganese Carbonate, Cobalt Tetroxide and Nickel Oxide as Main Raw Materials 0.5 co 0.28 mn 0.16 Si 0.03 Zr 0.03 o 1.98 f 0.04 . 363.2g of lithium carbonate, 10.6g of lithium fluoride, 382.1g of nickel oxide, 230.0g of cobalt tetroxide, 32.9g of zirconia, 18.4g of silicon dioxide, and 188.2g of manganese carbonate were added to the pre-grinding tank, and 3000ml of absolute ethanol was added, and the Pre-grind on a rod mill for 24 hours. Take the pre-grinded material out of the pre-grinding tank, add 6000ml of absolute ethanol, and grind it on a coarse grinder for 200 minutes. After mixing the raw materials evenly, take out the material from the coarse grinder and dry it at 80°C. The powder obtained after drying was calcined at 900°C for 12 hours, and then cooled with the furnace.

specific Embodiment 3

[0049] Preparation of LiNi by Lithium Carbonate, Manganese Carbonate, Cobalt Tetroxide and Nickel Oxide as Main Raw Materials 0.5 co 0.28 mn 0.16 Si 0.03 Zr 0.03 o 1.98 f 0.04 . 363.2g of lithium carbonate, 10.6g of lithium fluoride, 382.1g of nickel oxide, 230.0g of cobalt tetroxide, 32.9g of zirconia, 18.4g of silicon dioxide, and 188.2g of manganese carbonate were added to the pre-grinding tank, and 3000ml of absolute ethanol was added, and the Pre-grind on a rod mill for 24 hours. Take out the pre-grinded material, add 6000ml of absolute ethanol, grind it on a coarse grinder for 200 minutes, transfer the material into a fine grinder, grind it finely for 200 minutes, and dry the finely ground mixture at 80°C. The powder obtained after drying was calcined at 900°C for 12 hours, and then cooled with the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com