Temperature control method and system for excimer laser

An excimer laser and temperature control system technology, applied in lasers, phonon exciters, laser parts and other directions, can solve the problems of insufficient temperature control ability and mutual influence of excimer lasers, and achieve high energy conversion efficiency and energy stability properties, and the effect of improving temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

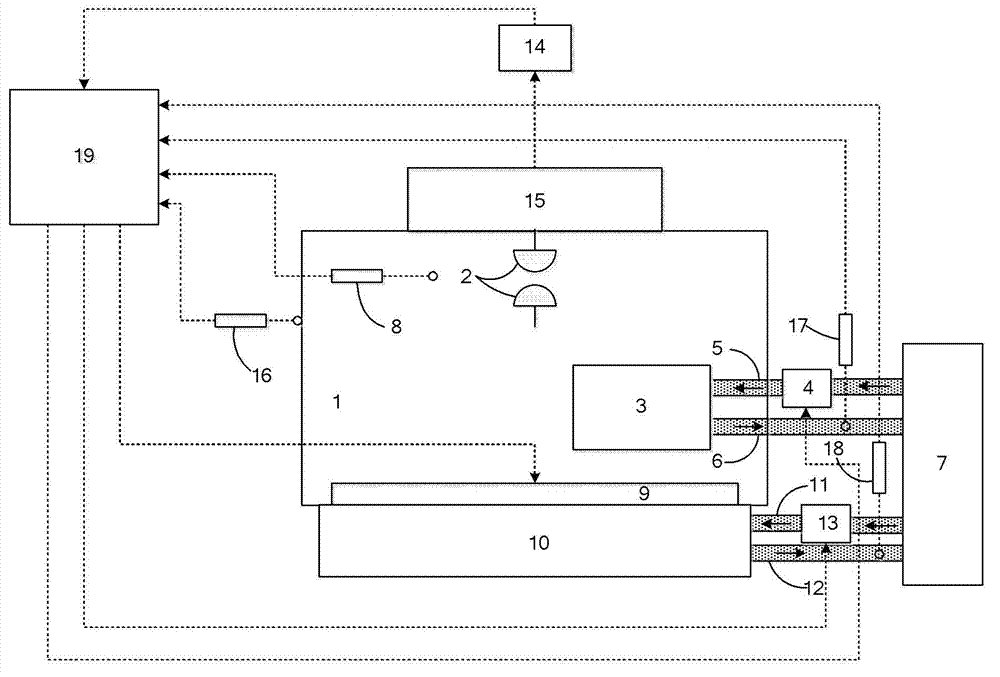

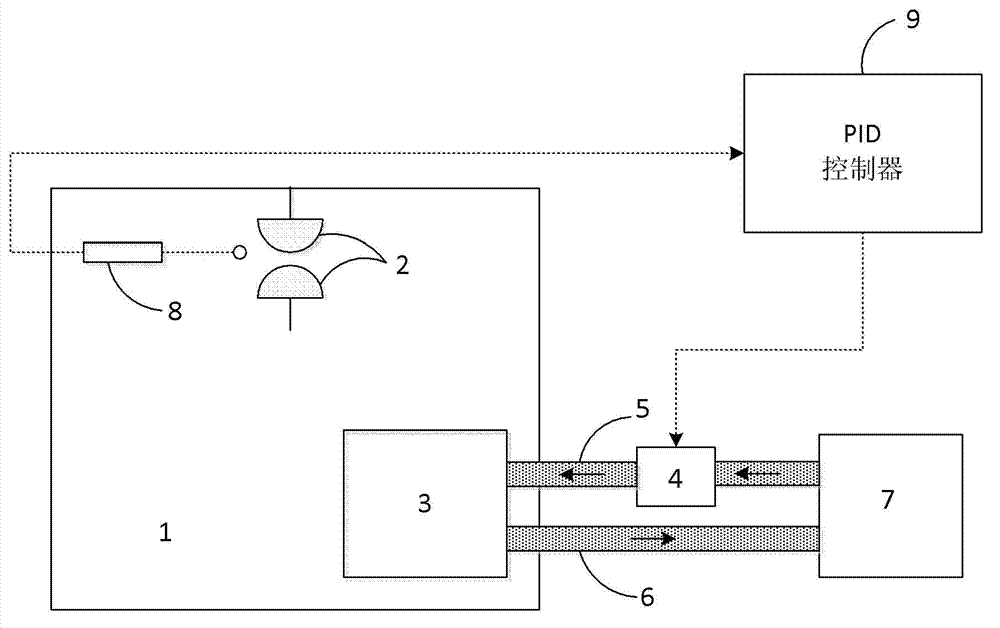

[0027] As mentioned above, the excimer laser includes a discharge cavity, and the discharge cavity includes components such as discharge electrodes. The traditional temperature control system includes a heat exchange system and a cooling system. The heat exchange system is used to absorb the heat in the discharge chamber, and input the cooling water from the cooling system through the water inlet pipe, and output the heated water to the cooling system through the water outlet pipe, so as to discharge the heat out of the discharge chamber; the cooling system will be controlled by the heat exchange system The heated water output by the water outlet pipe is cooled, and the cooling water is output to the water inlet pipe of the heat exchange system, so as to circulate and input the cooling water to the heat exchange system.

[0028] As mentioned above, a flow regulating valve is installed on the water inlet pipe of the heat exchange system, and a temperature sensor is installed ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com