Electric screening system

A sub-system and electric screen technology, which is applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of low screening efficiency and low energy consumption, improve the working environment and working conditions, reduce energy consumption, and expand the scope of application wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

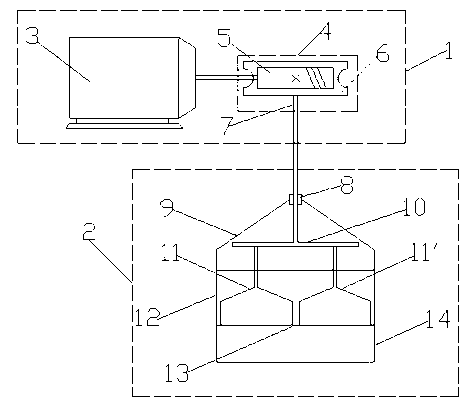

[0013] Such as figure 1 As shown, the high-efficiency electric screening system of the present invention includes an electric device 1 and a screening device 2; the electric device 1 is composed of a motor 3 and a transmission device 4; The rotating shaft 7 is formed; the screening device 2 is composed of a bearing 8, a housing 9, a brush bracket 10, a brush 11 and a brush 11′, a sieve groove 12, a screen 13, and a material receiving device 14; the worm 5 is directly connected with the motor 3, and the turbine 6 Directly connected with the rotating shaft 7, the brush holder 10 is fixed on the rotating shaft 7.

[0014] The motor 3 drives the brush 11 and the brush 11′ assembled on the brush bracket 10 through the transmission device 4 to rotate circularly.

[0015] The brush support 10 is a two-leg type, and the two legs are on the same straight line. The brush 11 and the brush 11' are symmetrically connected and assembled on the two legs of the brush support 10, and the widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com