Processing method of golf head inner surface partial thickness cutting

A technology of golf head and processing method, which is applied in the direction of processing working medium, metal processing equipment, electrochemical processing equipment, etc., can solve the problems of low efficiency and low precision, and achieve cost reduction, high precision, and fast processing speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

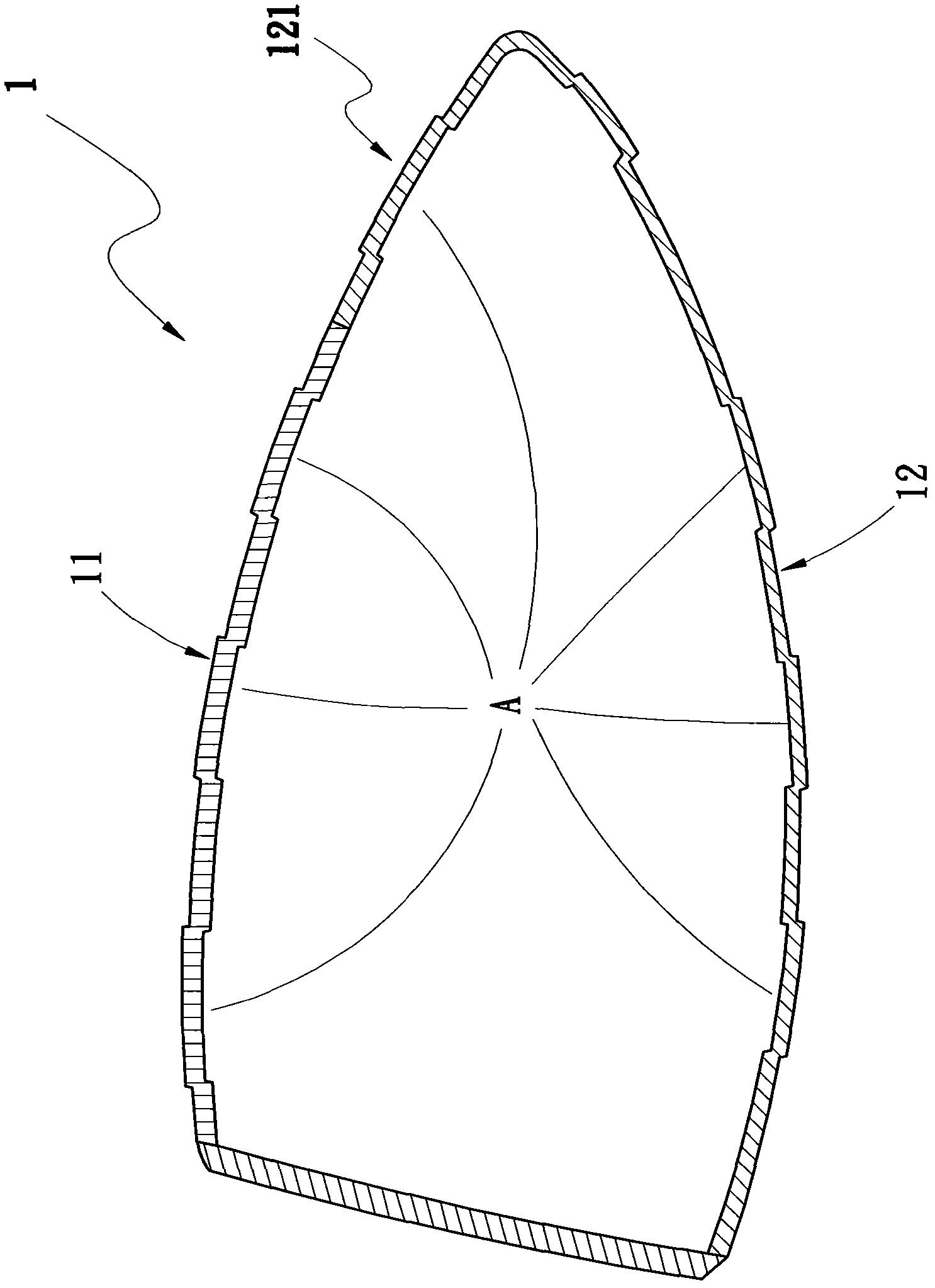

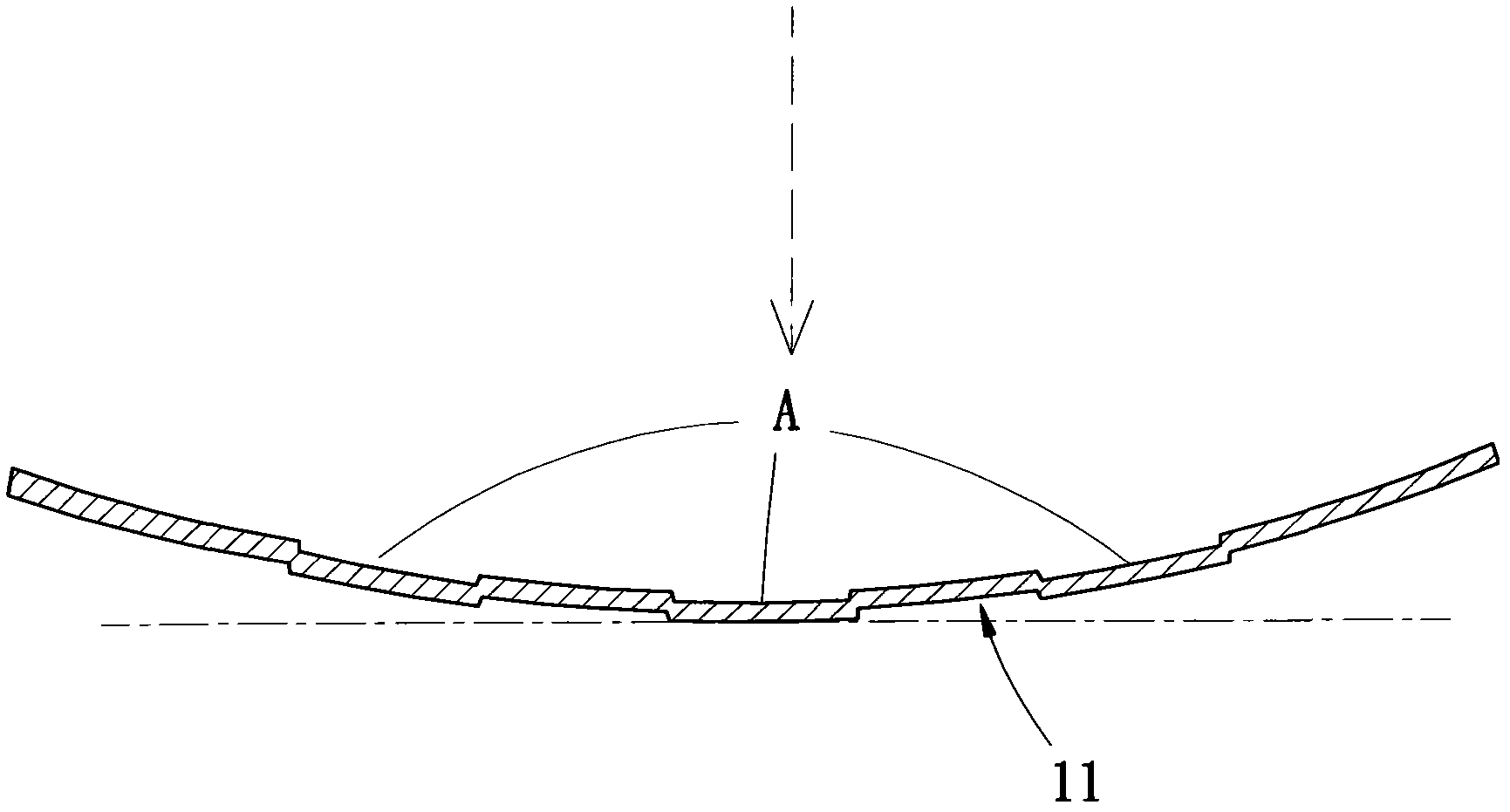

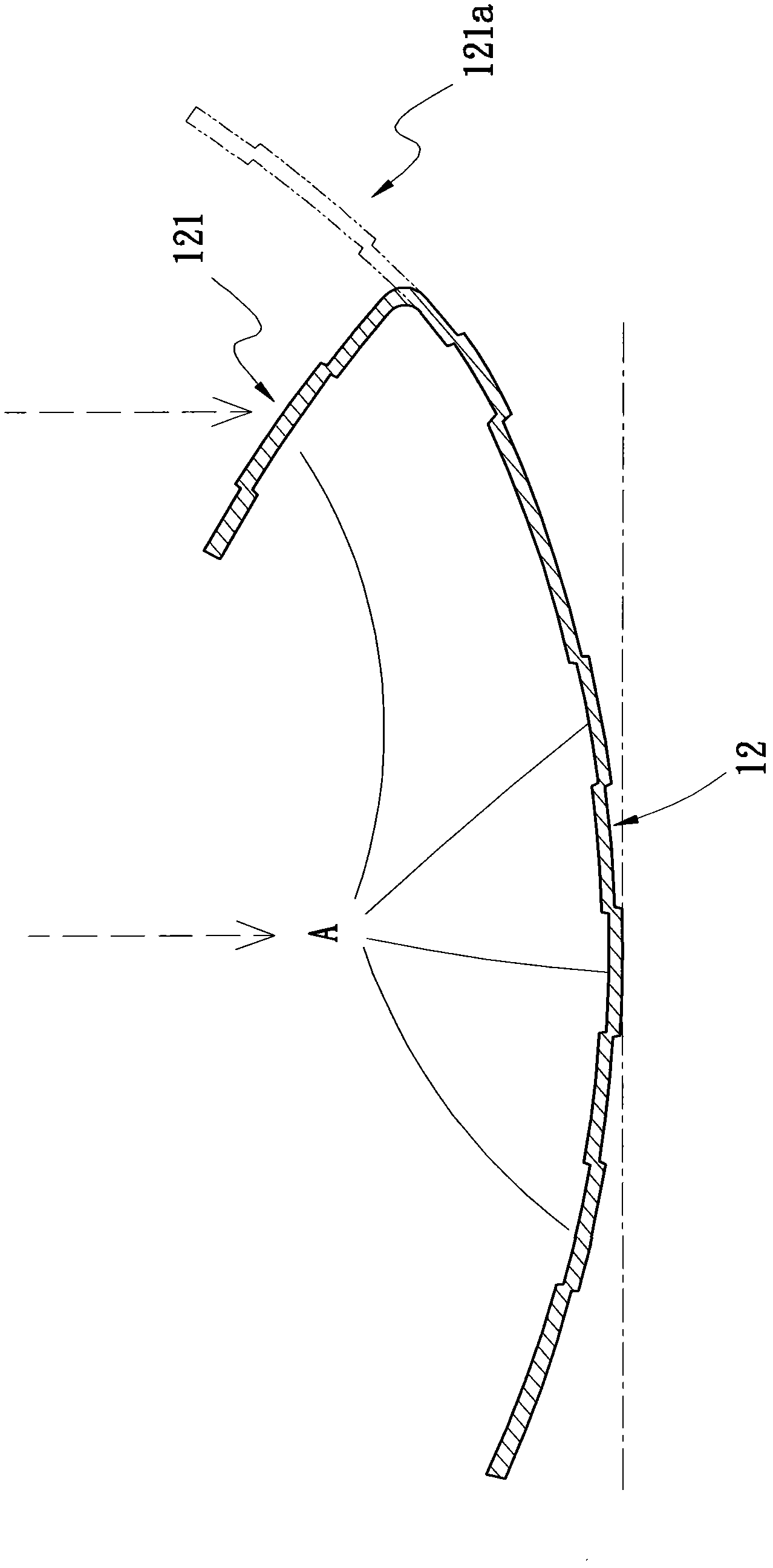

[0025] In order to further understand the features and technical content of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

[0026] The present invention provides a processing method for reducing the local thickness of the inner surface of the golf head. Please refer to Figure 4 As shown, the golf head 2 is for the upper cover 21 or the bottom plate 22 of the general golf wood club head or hollow ball head casting, forging or casting and forging semi-finished products. When the upper cover 21 or the bottom plate 22 exceeds the required original weight by 20% If it is within the limit, the thickness 23 of the inner surface of the upper cover 21 or the bottom plate 22 is reduced by means of ECM (Electro chemical machining) or precision electrochemical machining (PEC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com