Method for removing metal in high-acid heavy crude oil

A technology for heavy crude oil and demetallization agent, which is applied in chemical dehydration/demulsification, petroleum industry, refined hydrocarbon oil, etc. High metal removal rate and small dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

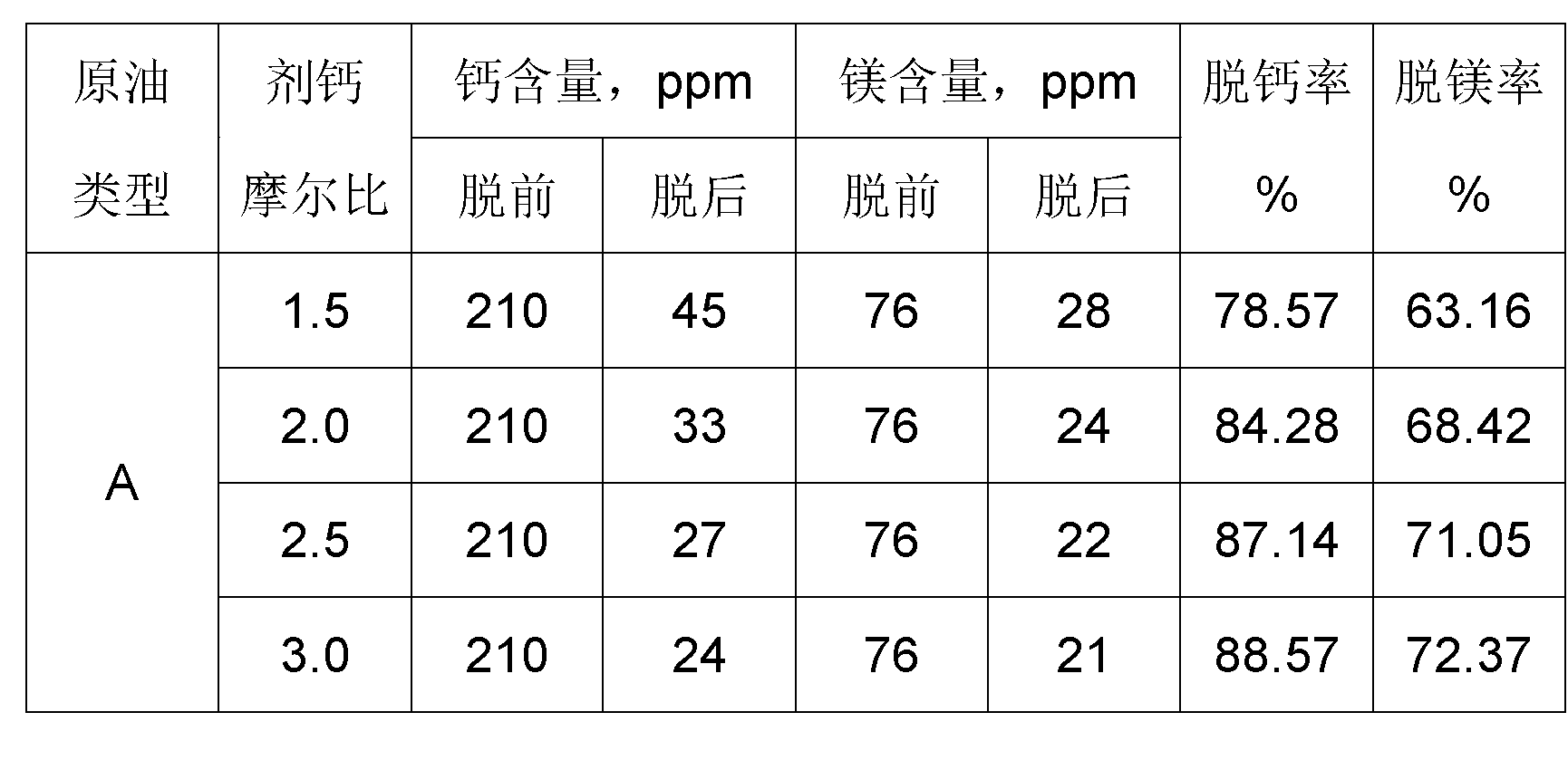

[0020] Under the condition of 90°C, mix the demetallization agent with the molar ratio of the crude oil to be removed to the calcium agent of 1.5, 2.0, 2.5, and 3.0, the water injection with the weight of 6% of the crude oil, and the demulsifier of 30ppm. In the electric desalination tank, the DPY-2B type electric desalination demulsifier evaluation instrument is used to conduct oil-water separation experiments. The electric desalination temperature is 125°C, the strong electric field strength is 900V / cm, the residence time is 3 to 6 minutes, and the weak electric field strength is 400V / cm cm, the residence time is 5-8 minutes, and the settling time is 30 minutes. The stripped crude oil was pretreated by dry ashing, and the metal content was determined by plasma emission spectrometry. The results are shown in Table 1.

[0021] Table 1 Table of metal content in crude oil before and after the experiment

[0022]

[0023] It can be seen from Table 1 that for the experimental...

Embodiment 5~6

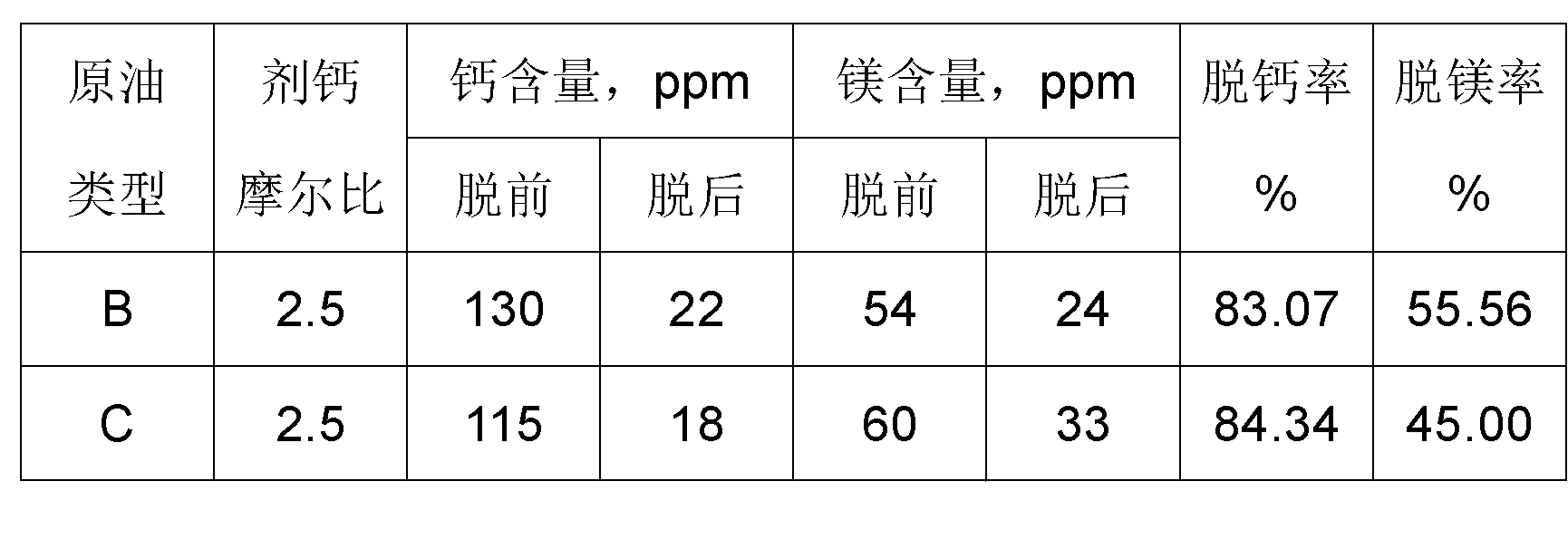

[0025] Select experimental crude oils B and C as the crude oils to be tested respectively. Under the condition of 120°C, mix the demetallizing agent with a molar ratio of 2.5 between the crude oil to be desorbed and the calcium agent, water injection with a weight of 6% of the crude oil, and 30 ppm demulsifier. The method of Example 1 was used for the desalination and dehydration experiment, and the results are shown in Table 2.

[0026] Table 2 Table of metal content in crude oil before and after the experiment

[0027]

[0028] It can be seen from Table 2 that when the molar ratio of agent to calcium is 2.5, it also has a good demetallization effect on experimental crude oils B and C.

Embodiment 7~10

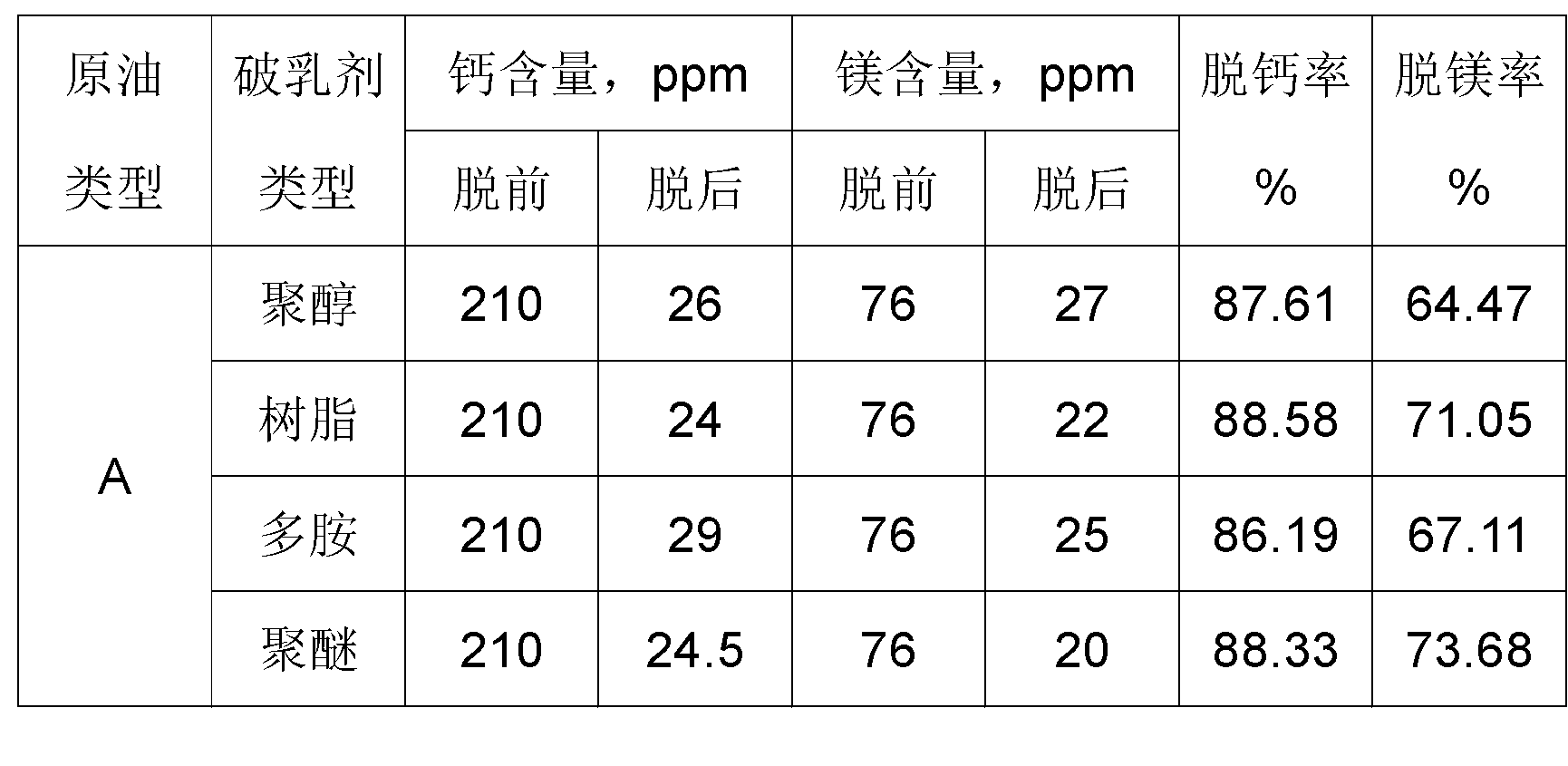

[0030] Select several demulsifiers widely used in domestic refineries. Under the condition of 120°C, mix the demetallizer with a molar ratio of 2.5 between crude oil and calcium agent to be removed, water injection with a weight of 10% of crude oil, and 30ppm demulsifier. The method of Example 1 is used to carry out the experiment of electric desalination and dehydration. The results are shown in Table 3.

[0031] Table 3 Table of metal content in crude oil before and after the experiment

[0032]

[0033] It can be known from Table 3 that under the demetallization method of the present invention, the demetallizer and demulsifier used have good compatibility.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com