Viscosity index improver for recombined type lubrication oil

A technology for improving viscosity index and lubricating oil, applied in lubricating compositions, additives, petroleum industry, etc., can solve the problems of difficulty in taking both thickening ability and shear stability into consideration, high price, and achieve good compatibility and storage. The effect of stability, reduced dosage, and lower cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

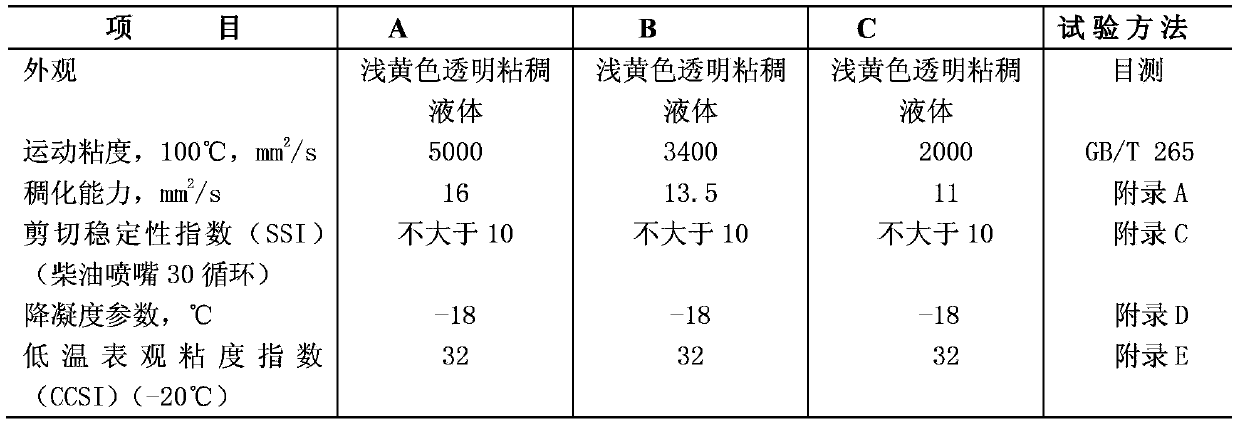

Image

Examples

Embodiment 1

[0029] Select the following components in weight percent: ethylene-propylene copolymer 0.1%; styrene or styrene / conjugated diene polymer 0.1%; base oil 99.8%; first ethylene-propylene copolymer and styrene or benzene The solid in the ethylene / conjugated diene polymer is cut into small pieces, and then added to the base oil, while raising the temperature and stirring mechanically or pneumatically, when the temperature rises to 70-400°C, stir at a constant temperature until the mixing or grafting is completed.

[0030] Moreover, the molecular weight can be degraded or even dehydrated while grafting until the requirements are met.

[0031] And the ethylene-propylene copolymer is grafted with styrene or styrene / conjugated diene polymer. In the present invention, styrene or styrene / conjugated diene polymer is grafted on the ethylene-propylene copolymer, and the saturated hydrocarbon recombination of the two can effectively improve the thickening ability of the soft environment visc...

Embodiment 2

[0033] Select the following components by weight percentage: ethylene-propylene copolymer 30%; styrene or styrene / conjugated diene polymer 30%; base oil 40%; first ethylene-propylene copolymer and styrene or benzene The solid in the ethylene / conjugated diene polymer is cut into small pieces, and then added to the base oil, while raising the temperature and stirring mechanically or pneumatically, when the temperature rises to 70-400°C, stir at a constant temperature until the grafting is completed.

Embodiment 3

[0035] Select the following components by weight percentage: ethylene-propylene copolymer 20%; styrene or styrene / conjugated diene polymer 20%; base oil 60%; first ethylene-propylene copolymer and styrene or benzene The solid in the ethylene / conjugated diene polymer is cut into small pieces, and then added to the base oil, while raising the temperature and stirring mechanically or pneumatically, when the temperature rises to 70-400°C, stir at a constant temperature until the mixing or grafting is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com