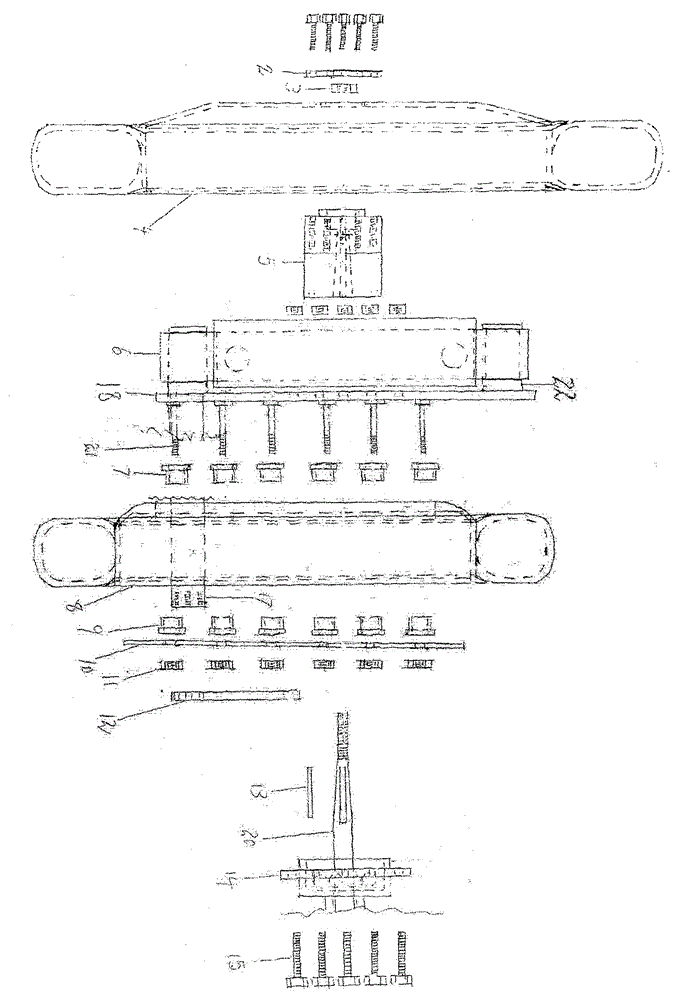

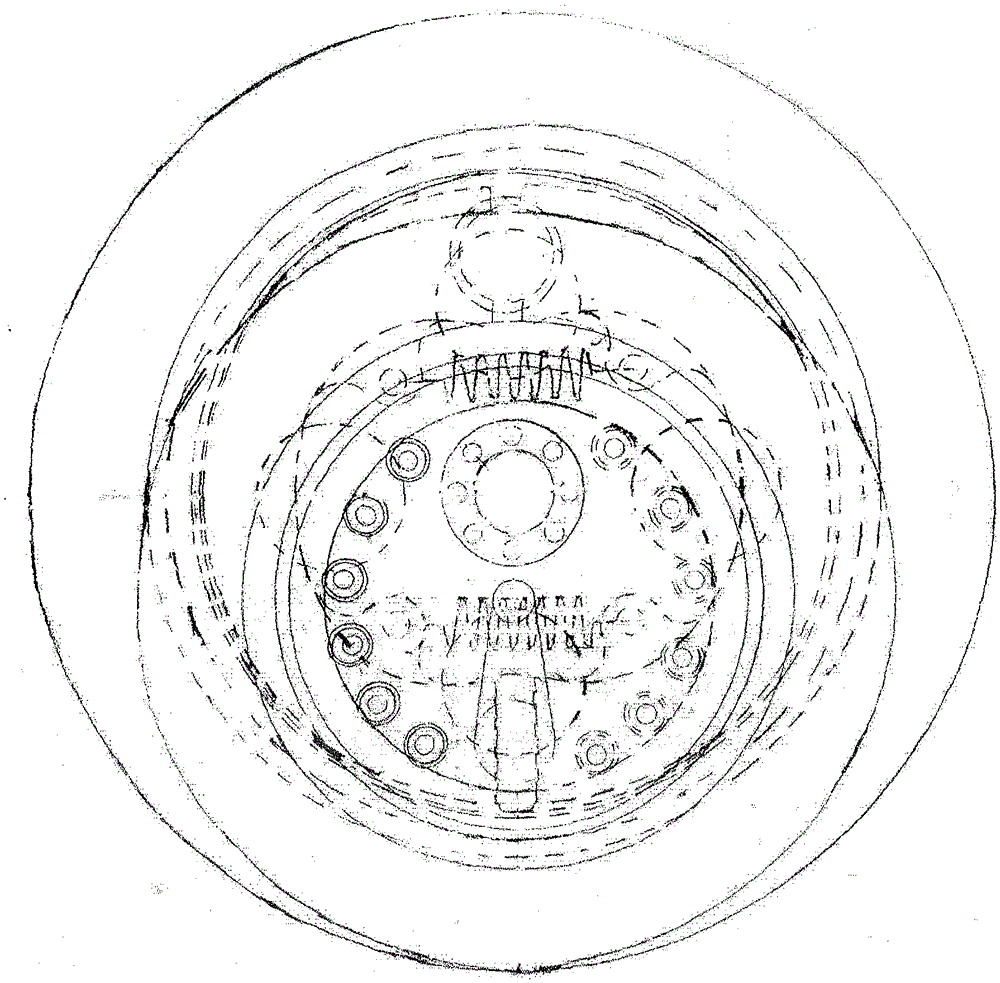

Large and small wheel structure

A technology of large and small wheels and rear wheels, applied in the field of large and small wheel structures, can solve the problems of large occupied compartment area and high center of gravity of special vehicles, and achieve the effects of reducing vehicle height, reducing rollover accidents and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] At the outer axle tube 14 outside the rear wheel axle 20, put on the counter-perforation near the center of the booster plate 10, and then align the counter-perforation on the concave side of the inner side of the built-in wheel 8 with the rear vehicle. The outer axle tube 14 outside the axle 20 is also put on.

[0028] The side of the fixing plate 18 with the several first cylindrical fixing shafts 21 faces inward, and the opposite holes in the middle of the circular plane are aligned with the outer plane of the rear wheel shaft 20, so that there are long strips on the plane of the fixing plate 18. The part of 17 is placed at the lowermost end, and the pair of perforations in the middle of the circular plane is sleeved at the protrusion of the top plane of the outer axle tube 14 outside the rear wheel axle 20. After the small pairs of perforations are matched with the protruding small pairs of perforations on the top plane of the outer axle tube 14 outside the rear whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com