Production method of aluminum alloy conductor rail

A production method and technology of conductive rails, which are applied in the production field of aluminum alloy conductive rails, can solve the problems of reducing the conductivity of aluminum and that the conductivity cannot meet the technical requirements, and achieve the effect of meeting high strength and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

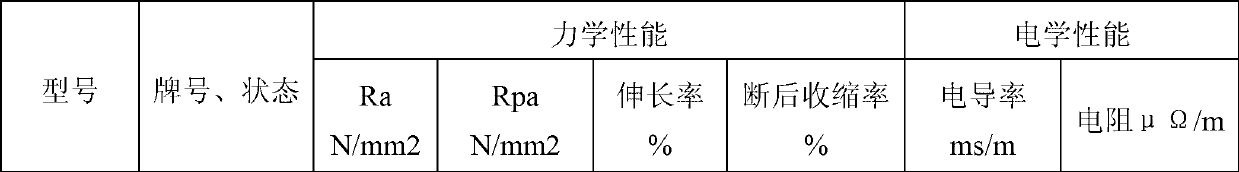

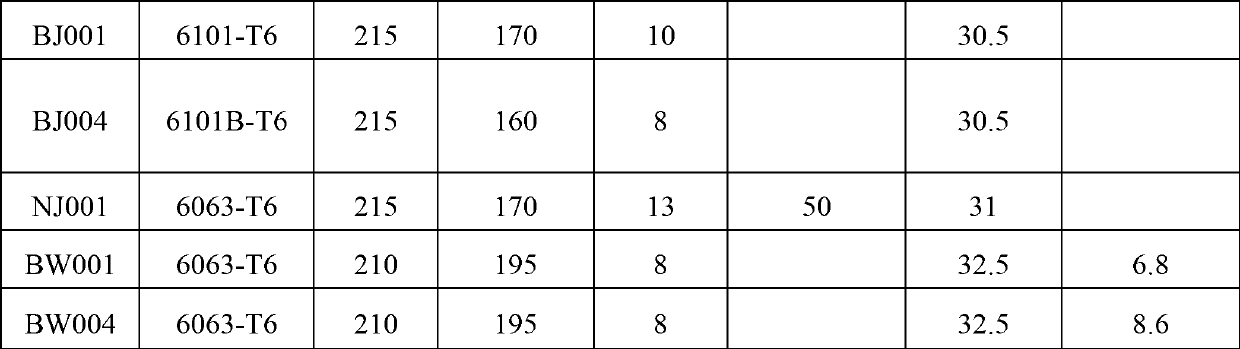

[0026] In the production method of the aluminum alloy conductive rail of the present invention, in the production process of the aluminum alloy, the optimized internal control components and standard components of other metal elements are shown in Table 3.

[0027] Table 3 Standard alloy composition and optimized internal control composition

[0028]

[0029] In industrial production, the conventional aging system of 6101-T6 is 175℃×(6-8) hours, the conventional aging system of 6063-T6 is 175℃×8 hours or 185℃×2 hours and 205℃×1 hour, 175℃ × 8 hours is generally suitable for industrial materials, 185 ° C × 2 hours and 205 ° C × 1 hour are used for some architectural profiles.

[0030] No matter for 6061 alloy or 6063 alloy, the artificial aging process of 175℃×8 hours can achieve good results when the performance requirements are normal and the conductivity requirements are normal (≤31MS / M). In actual production, BJ and NJ conductor rails , is to adopt the aging process, bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com