Oil atomizer base with reverse locking function

A fuel injector, reverse lock technology, applied in the direction of machine/engine, fuel injection device, engine components, etc., can solve the problems of looseness, many uncontrollable factors, not a connection scheme, etc., to achieve excellent durability and stability, The effect of simplifying operation procedures and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

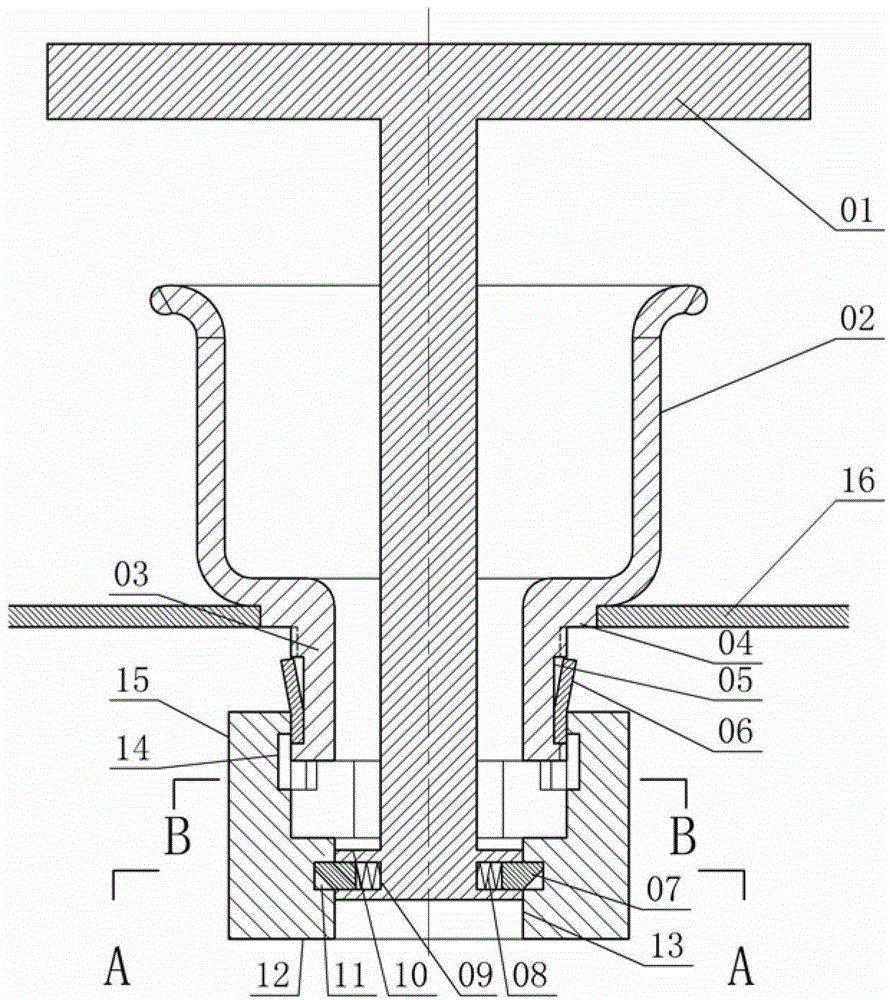

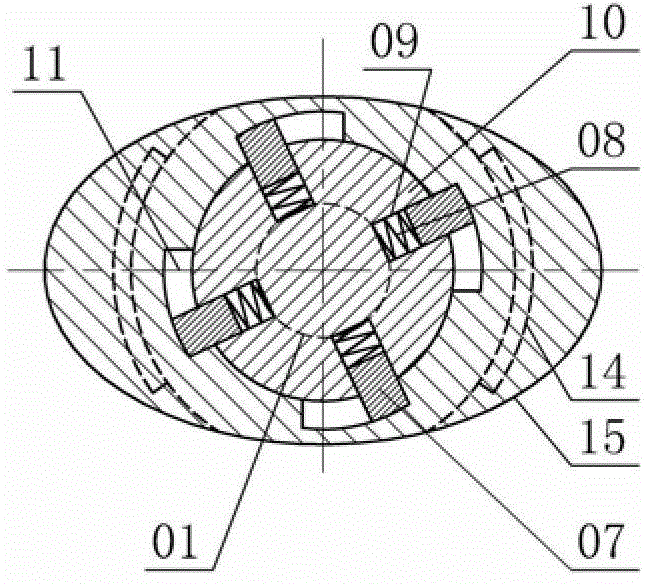

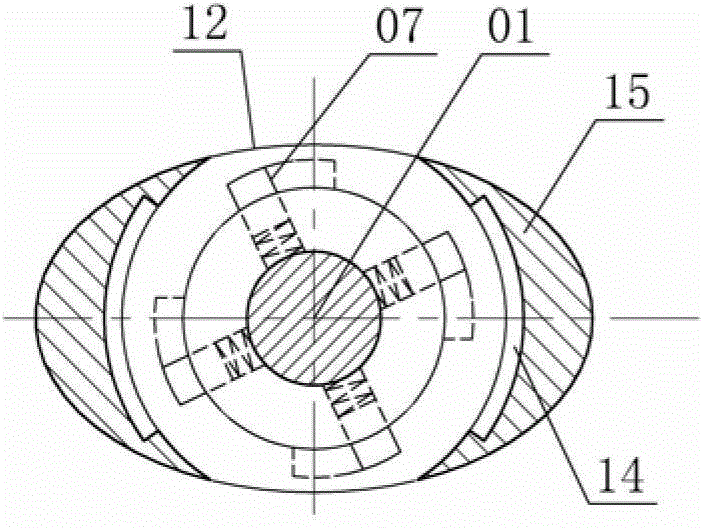

[0032] The fuel injector base with reverse locking function consists of operating rod 01, cup body 02, coupling cylinder 03, convex edge 04, piece groove 05, spring piece 06, latch pin 07, spring 08, spring groove 09, rotating disk 10 , latch groove 11, anchor seat 12, operation hole 13, positioning groove 14 and positioning block 15 constitute.

[0033] The cylindrical cup body 02 and the combination tube 03 are integrated, the cup body 02 is located below the combination tube 03 and the outer diameter of the cup body 02 is smaller than the outer diameter of the combination tube 03, and there is a circle at the junction of the cup body 02 and the combination tube 03 The annular protruding edge 04 has a through hole on the fuel pipe 16, and the protruding edge 04 is inserted into the through hole and forms an interference fit relationship with it.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com