Silicon substrate double-paddle structure quartz beam resonant micro pressure sensor

A pressure sensor, vibrating micro technology, applied in the direction of measuring fluid pressure, measuring fluid pressure through electromagnetic elements, measuring force by measuring the frequency change of stressed vibration elements, etc., can solve the difficulty and difficulty of excitation and detection of resonators. Problems such as processing the resonator structure to achieve the effect of low cost, no hysteresis and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

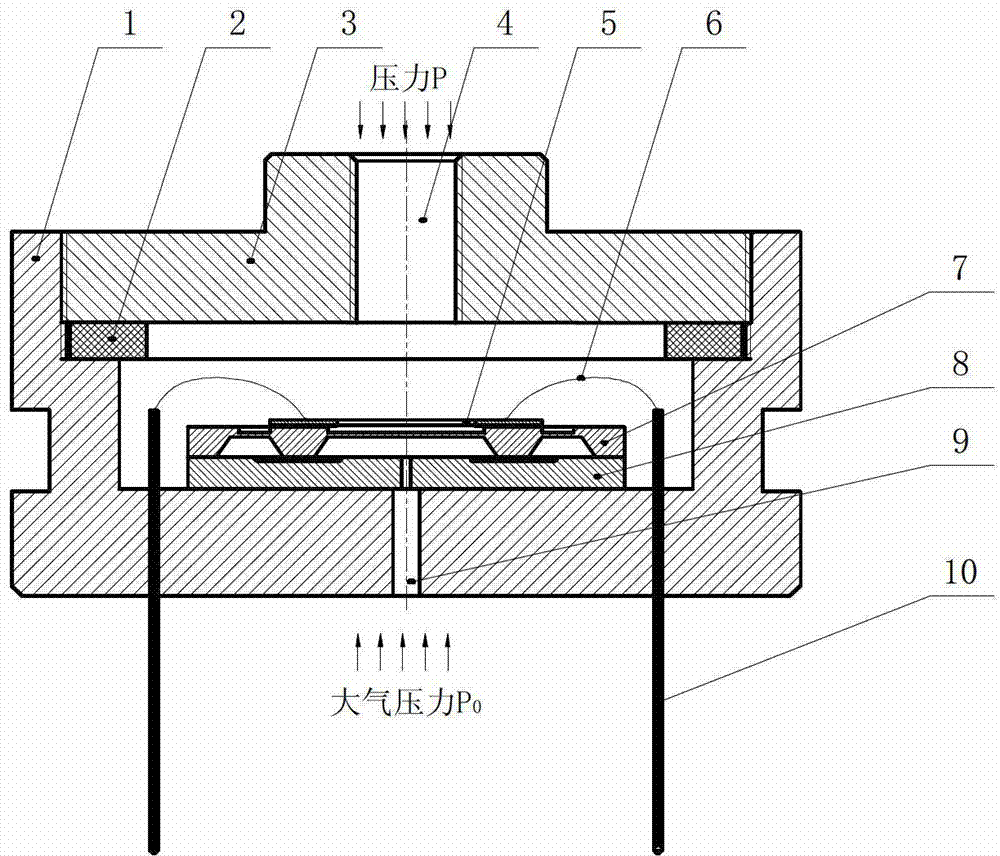

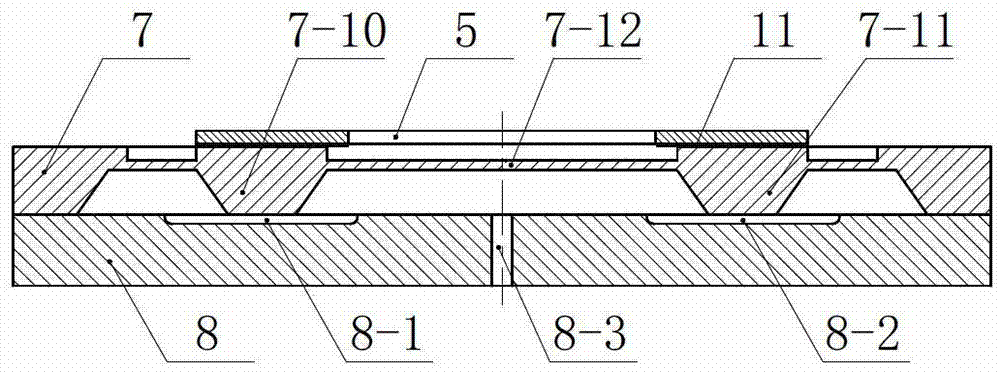

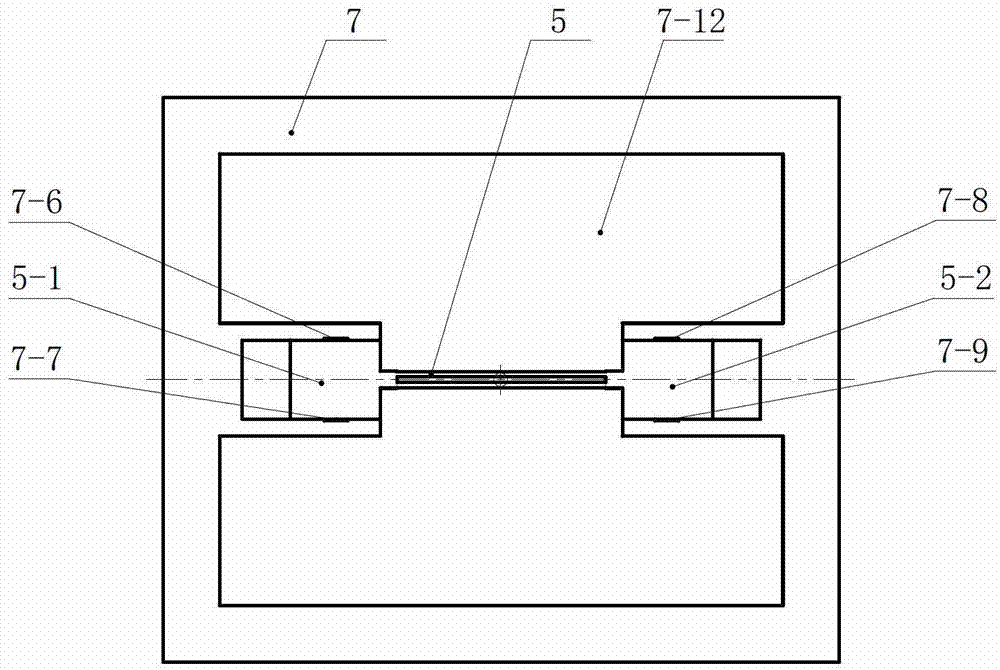

[0025] refer to figure 1 , a silicon-based double-island structure quartz beam resonant micro pressure sensor, comprising a housing 1, the cavity of the housing 1 communicates with the pressure hole 9 on the upper bottom of the housing 1, and a sensor chip and two sensors are arranged in the cavity of the housing 1 Each electrode pin 10, the first pressure soldering block 5-5 on the base of the quartz beam 5, the second pressure soldering block 5-6 are respectively connected with the two electrode pins 10 by ultrasonic thermocompression welding with gold wire 6, The pressure ring 3 and the upper part of the housing 1 are fixed together by threaded connection. The joint is provided with an elastic sealing ring 2. The elastic sealing ring 2 prevents gas from leaking from the threaded connection. The cavity is connected, the gas to be measured enters the cavity of the shell 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com