Absorption rotary wheel simulated condition dynamic automatic test system

An automatic test system and runner technology, applied in the field of air pollutant treatment, can solve the problems of not really reflecting the runner adsorption and other properties, unable to comprehensively evaluate the runner quality, and the test conditions are not strict, and achieve the test process. Continuous and stable and reliable, high degree of automation, convenient clamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments in the drawings:

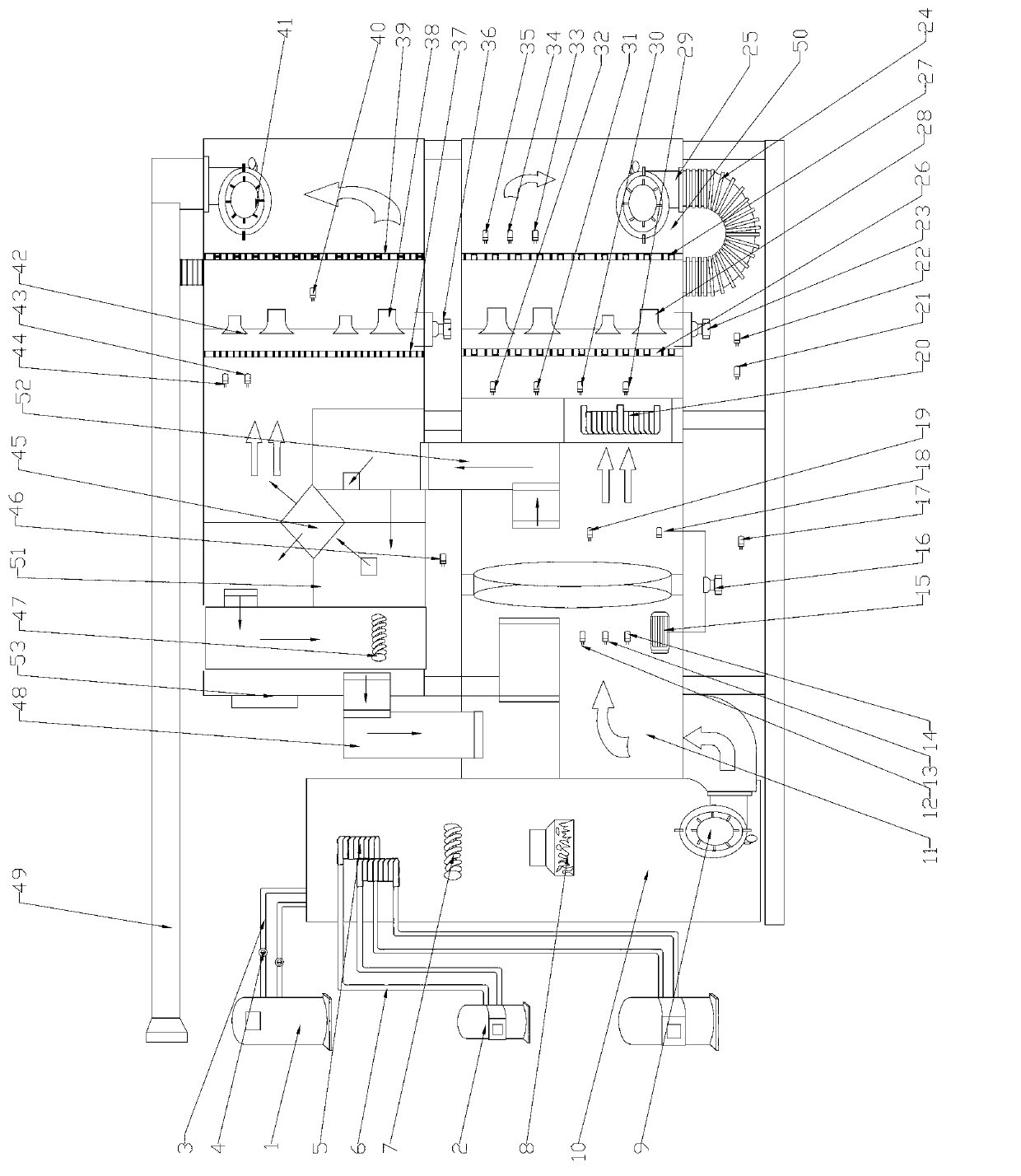

[0024] Such as figure 1 As shown, the present invention mainly includes a first chamber body 10, a second chamber body 11, a third chamber body 50, a fourth chamber body 42 and a fifth chamber body 51. The first chamber body 10 is provided with a plurality of first watches. The cooler 5, each first surface cooler 5 is connected to a cooler 2 through a cold air pipe 6. The first chamber body 10 is connected to the gas generating tank 1 through an air inlet pipe 3, and the air inlet pipe 3 is provided with an air inlet valve controller 4 that controls the opening and closing of the air inlet pipe. The first chamber body 10 is provided with a heater 7 and a humidifier 8, and the heater 7 and the humidifier 8 heat and humidify the gas in the first chamber body 10. Exhaust gas under simulated working conditions is generated from the gas generating tank 1, enters the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com