Acoustic test equipment-reverberation box

A technology for acoustic testing and reverberation box, which is used in measurement devices, scientific instruments, material analysis using sonic/ultrasonic/infrasonic waves, etc. It can solve the problem of high construction cost of reverberation chambers, inability to cut and measure specimens, and small size of specimens. Can not wait for the problem to achieve the effect of reducing the test area, convenient operation, and improving the sound insulation of the cabinet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

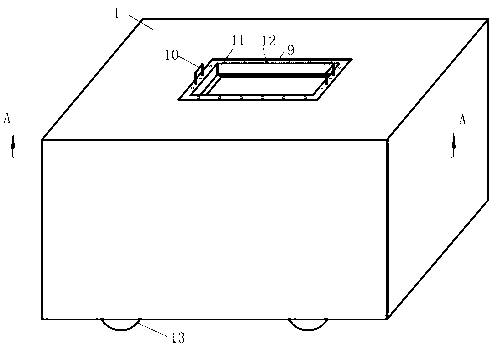

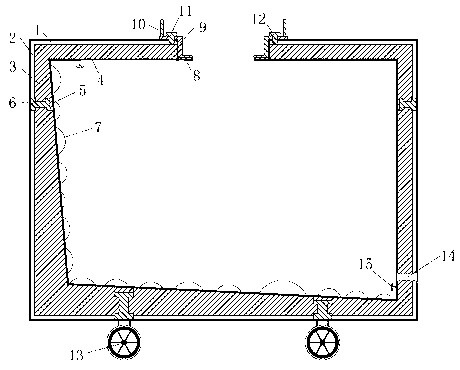

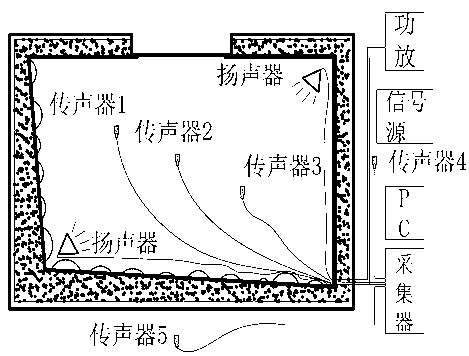

[0022] The thickness of each layer of the composite structure of the reverberation box is: the thickness of the steel plate of the inner box is 4mm, the thickness of the glass fiber cotton is 70mm, the thickness of the air layer is 10mm, and the thickness of the steel plate of the outer box is 3mm. The experiment was completed in a semi-anechoic room without other sound sources around. The measured background noise is 35.1dB. The inside of the box is painted with white enamel paint, which makes the inner surface of the box smooth and reduces the sound absorption coefficient of the inner box. Two loudspeakers are installed in the diagonal position in the reverberation box as the sound source of the test.

[0023] Three microphones are placed in the reverberation box, such as image 3 shown. The installation position of the reverberation box specimen is sealed by thick steel plates and sound-absorbing materials. The microphones 1, 2 and 3 in the box are not less than 0.3 met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com