Tubular piezoelectric vibrator

A piezoelectric vibrator, tubular technology, applied in the direction of generator/motor, piezoelectric effect/electrostrictive or magnetostrictive motor, electrical components, etc., can solve the problems of high working voltage and long response time, and achieve Effects of reduced amplitude loss, fast response time, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

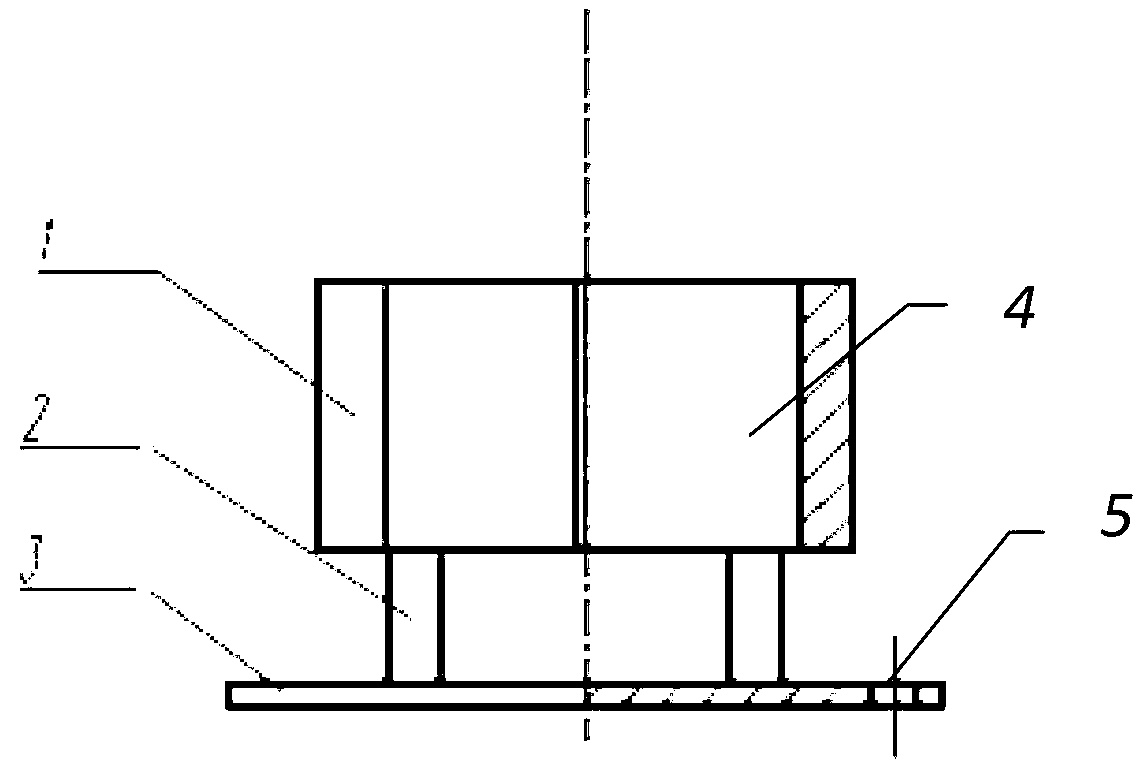

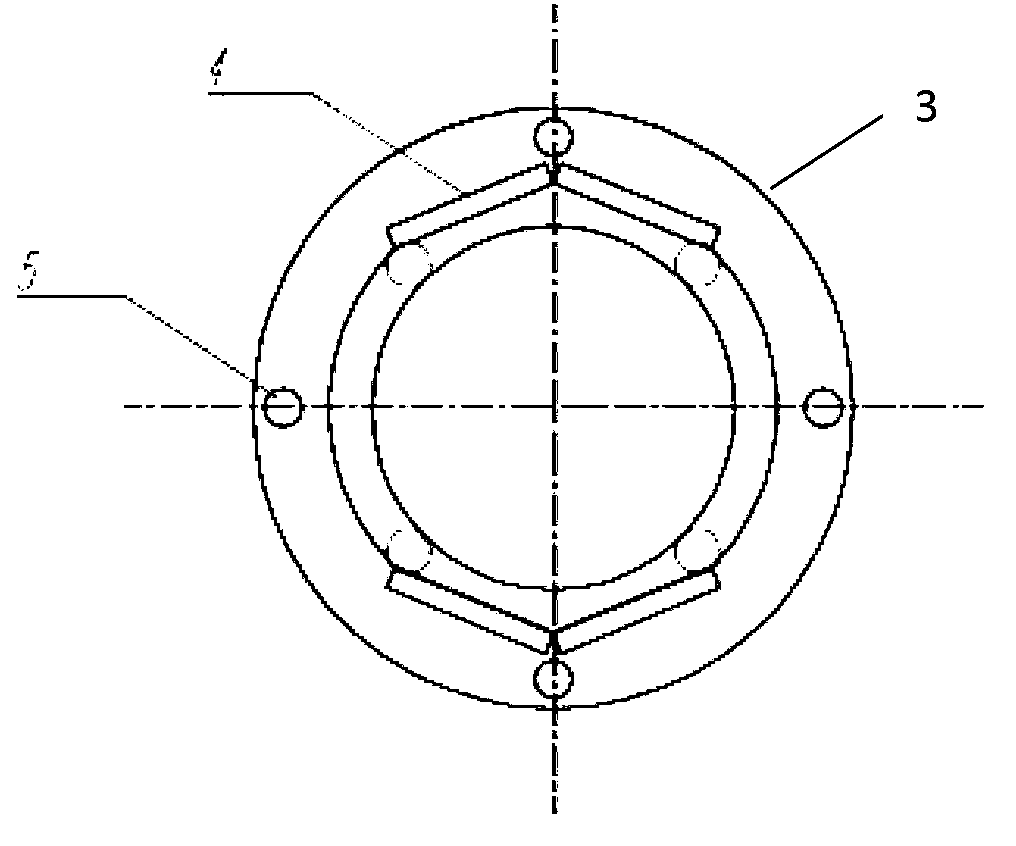

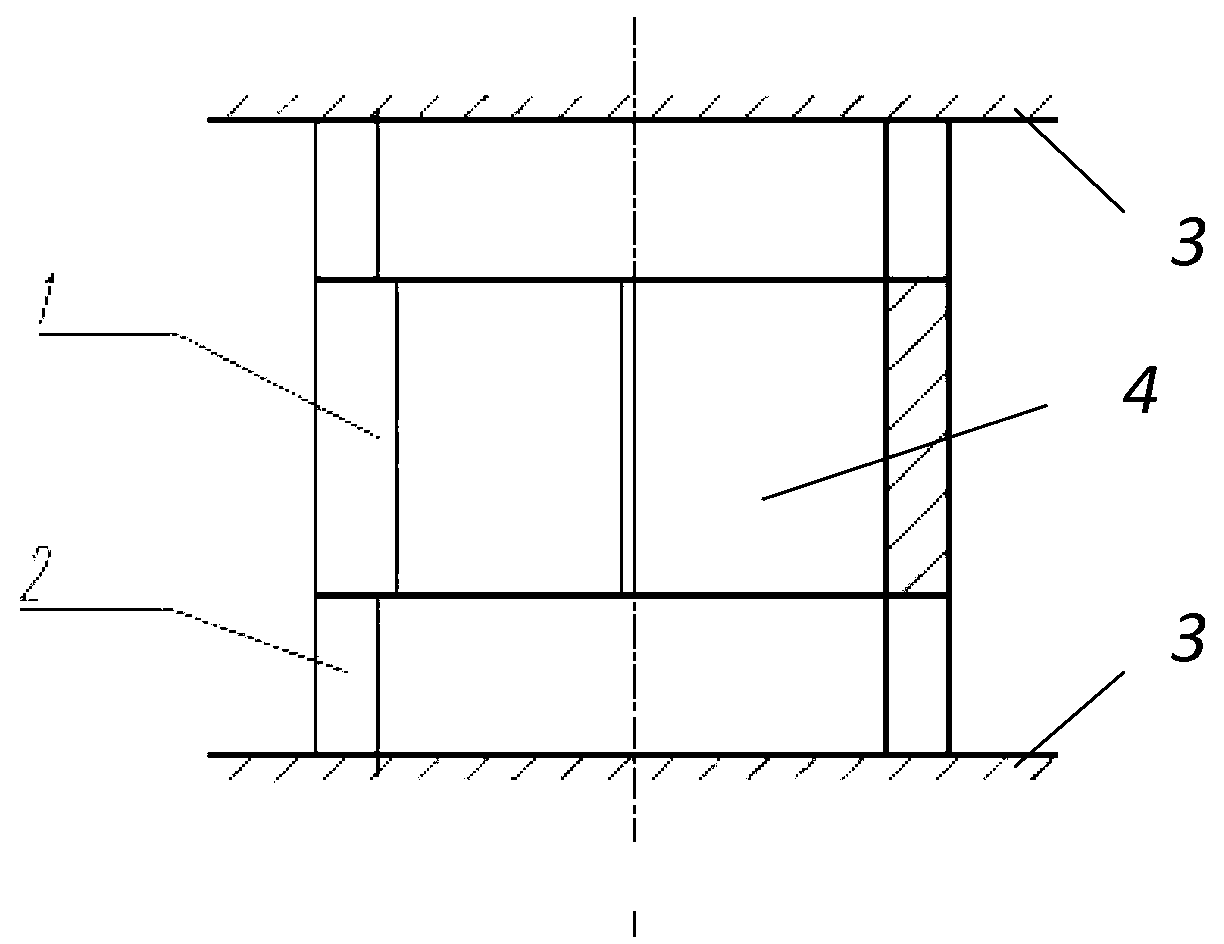

[0016] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

[0017] The tubular piezoelectric vibrator provided by the present invention includes a tubular vibrating body composed of an elastic matrix and a piezoelectric element. The vibrator also includes a bracket, which includes a bracket rod 2 and a fixing part 3; Polyhedral structure 1, the piezoelectric element 4 is pasted on the outer surface or inner surface of the elastic tubular polyhedron structure; one end of the support rod 2 is connected with the elastic tubular polyhedron structure or the piezoelectric element, and the other end of the support rod is connected with the fixed part 3 connections. Multiple support rods can be used, but the number of support rods should be less than or equal to the number of piezoelectric elements. One end of the support rod is connected to one or both ends of the tubular vibrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com