Quartz spargers for UV nanocuring chambers

A sprayer, UV technology, used in semiconductor/solid state device manufacturing, gaseous chemical plating, transportation and packaging, which can solve problems such as increasing cleaning time and reducing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

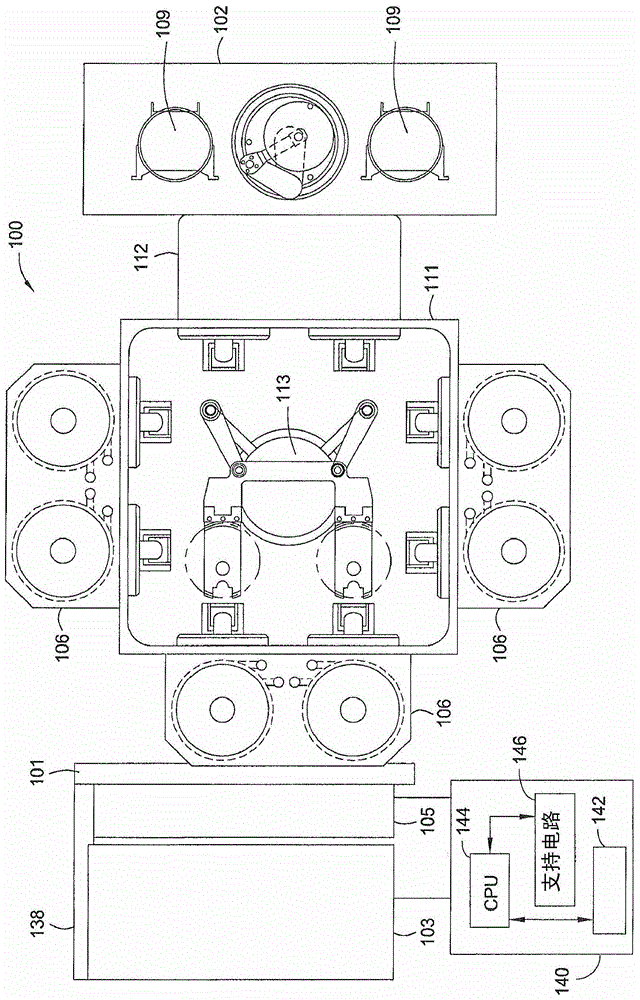

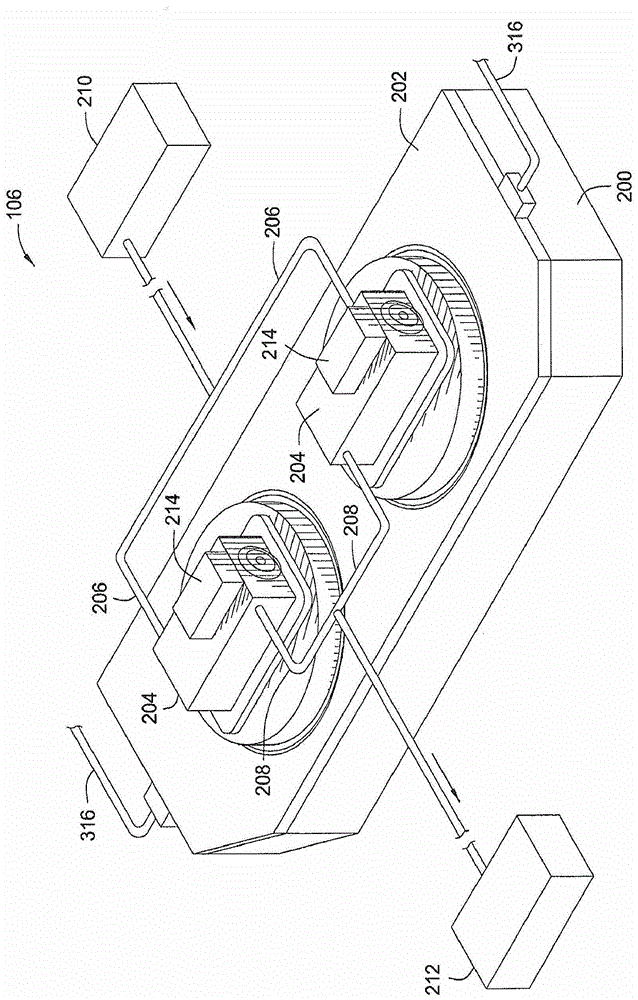

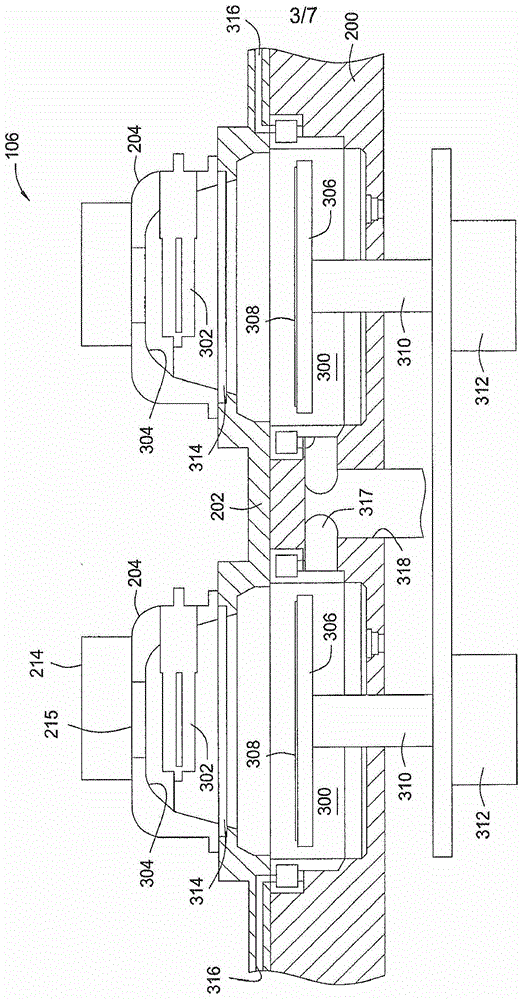

[0023] Embodiments of the invention generally provide a processing tool having an ultraviolet (UV) processing chamber and hardware within the processing chamber for controlling gas flow distribution within a processing region. Embodiments of the present invention enable processing tools to control the delivery, flow paths, distribution, and removal of gases within an ultraviolet processing chamber to better control various processes. Embodiments of the invention also provide methods of controlling airflow distribution within a processing tool and methods of cleaning the processing tool.

[0024] The design of the hardware allows for the distribution of a specific gas flow distribution across the substrate being processed in a UV chamber, lamp heating chamber, or other chamber where energy in the form of light is used to direct the substrate on or in the Thin films or catalyzed reactions are processed over the substrate. In addition, the process chamber walls, UV window and su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com