Green bean picker

A technology for picking machines and green beans, applied in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of instability, inconvenient steering, time-consuming and laborious harvesting, etc., and achieve the effect of stable performance and high degree of automation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

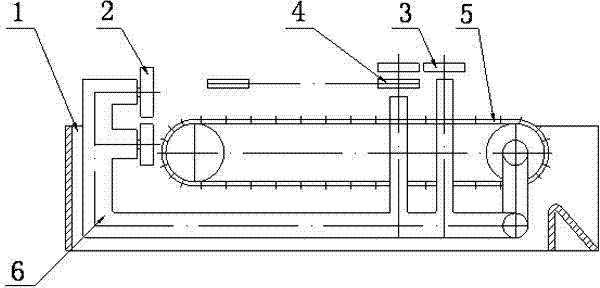

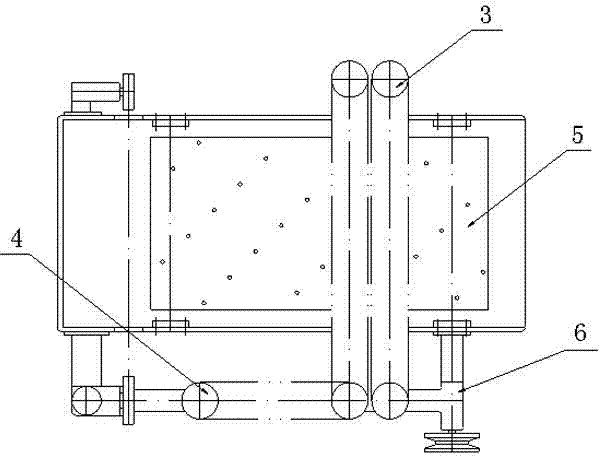

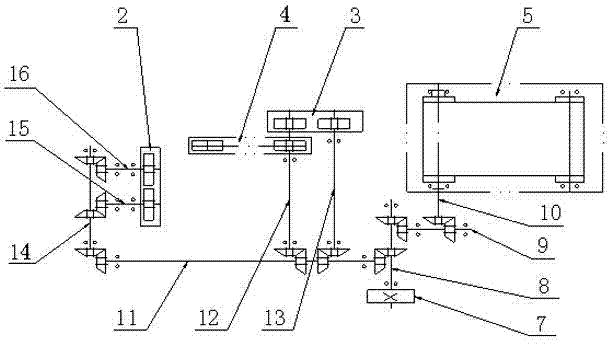

[0013] Such as Figure 1-3 As shown, the green bean picking machine of the present invention includes a frame 1, a flexible holder a2, a flexible holder b3, a handle changing mechanism 4, a toothed belt type picker 5 and a transmission mechanism 6, and the bottom of the frame 1 is fixedly connected with Transmission mechanism 6, a flexible clamper a2 is provided on one side of the frame 1, a toothed belt picker 5 is provided inside the frame 1, a flexible clamper b3 and a handle change mechanism 4 are provided on the upper part of the frame 1, and the handle change mechanism 4 Linked with the flexible holder b3, the transmission mechanism includes the driving wheel 7, the shaft a8, the shaft b9, the shaft c10, the shaft d11, the shaft e12, the shaft f13, the shaft g14, the shaft h15 and the shaft i16, and the driving wheel 7 drives the shaft a8 in turn , shaft b9 and shaft c10 are linked with the toothed belt picker 5, and the drive wheel 7 drives the shaft a1, shaft d11 and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com