Method of improving tank material finishing temperature

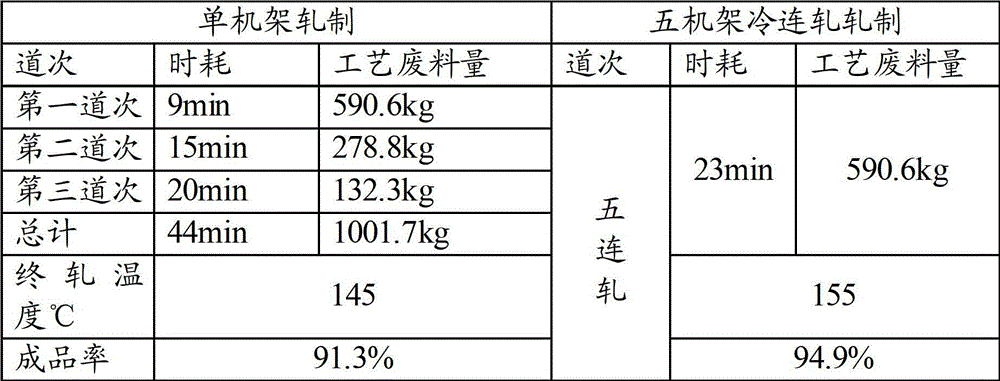

A technology of finishing rolling temperature and can body, applied in the field of aluminum alloy manufacturing, can solve the problems of prolonging process time, speed limitation, reducing production efficiency, etc., and achieves the effect of improving safety factor, reducing ignition rate and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

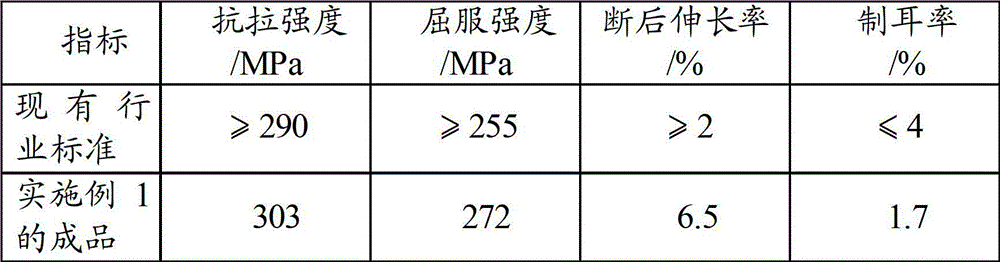

Examples

Embodiment 1

[0016] Embodiment 1 The method for improving the finishing temperature of can body material

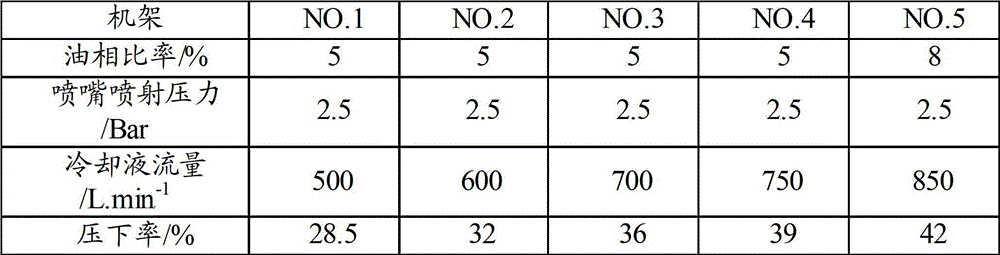

[0017] In this embodiment, a five-stand cold tandem rolling mill is used to roll 3104 can body materials. The thickness of the hot-rolled coil is 2.5 mm, the thickness of the finished coil is 0.275 mm, and the width is 1250 mm. The working roll diameter of the five stands is 470-508mm, the length of the roll body is 1727mm, the diameter of the backup roll is 1092-1168mm, the length of the roll body is 1626mm, and the temperature of the water-based coolant is 58°C. Water-based coolant (supplied by French Total) is used for lubrication, and the ratio of oil in the water-based coolant, nozzle injection pressure, water-based coolant flow rate and reduction rate in the five racks are controlled, as shown in Table 1. Show. The speed of the fifth frame is 1350m / min.

[0018] Table 1 Oil phase ratio, nozzle injection pressure, coolant flow rate and reduction ratio of five racks

[0019] ...

Embodiment 2

[0028] Embodiment 2 The method for improving the finish rolling temperature of can body material

[0029] In this embodiment, a five-stand cold tandem rolling mill is used to roll the can body material. The thickness of the hot-rolled coil is 2.3 mm, the thickness of the finished coil is 0.272 mm, and the width is 1550 mm. The working roll diameter of the five stands is 470-508mm, the length of the roll body is 1727mm, the diameter of the support roll is 1092-1168mm, the length of the roll body is 1626mm, and the temperature of the water-based cooling liquid is 60°C. Water-based coolant is used for lubrication, and the ratio of oil in water-based coolant, nozzle injection pressure, water-based coolant flow rate and reduction rate are controlled in five racks, as shown in Table 4. The speed of the fifth frame is 1380m / min.

[0030] Table 4 Oil phase ratio, nozzle injection pressure, coolant flow rate and reduction ratio of five racks

[0031]

[0032] Rolling is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com