Shock absorber device of medium-sized and heavy type trucks

A shock absorber, medium and heavy-duty technology, applied in vehicle parts, transportation and packaging, elastic suspension, etc., can solve the problems of complex structure and large volume, and achieve the effect of small volume, low cost and interference prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

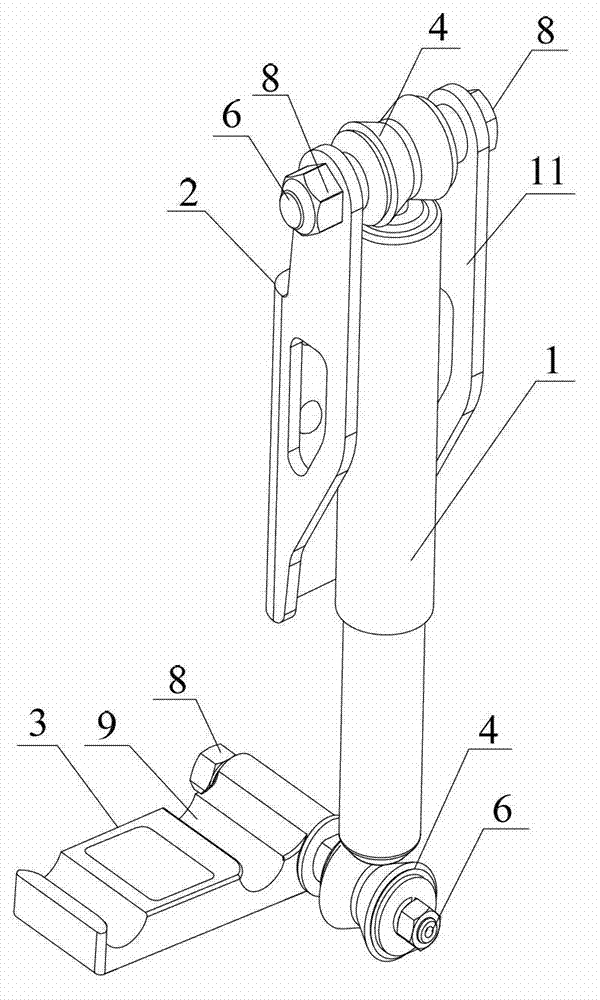

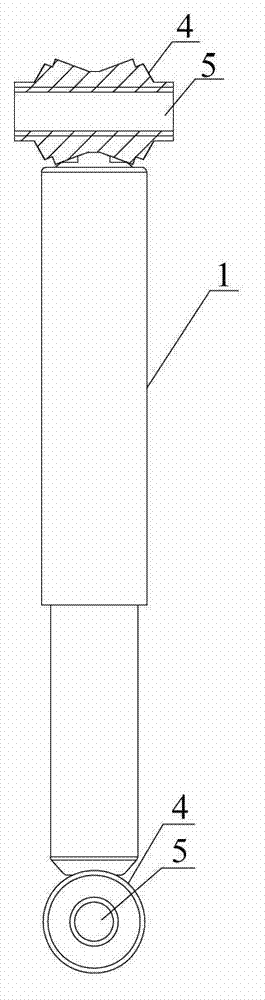

[0037] Such as Figure 1-9 As shown, the shock absorber device of the present invention is mainly composed of a shock absorber assembly 1, and the shock absorber assembly 1 is a monotube shock absorber. The upper and lower ends of the shock absorber assembly 1 are also respectively provided with connectors 4, such as figure 1 , 2 As shown, the two connectors 4 are perpendicular to each other, and the connectors 4 and the shock absorber assembly 1 are solidly integrated into one structure.

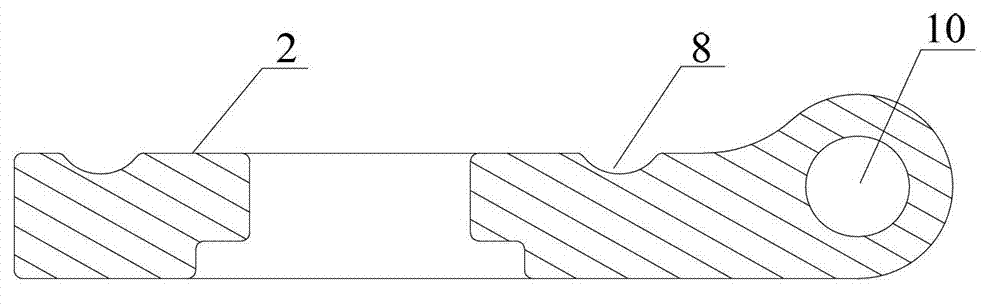

[0038] In order to facilitate the connection of the shock absorber assembly 1 on the vehicle body, an upper bracket 2 is also provided at the upper end of the shock absorber 1, such as figure 1 shown. In order to reduce the overall volume of the present invention, save space, and prevent the present invention from interfering with other parts on the vehicle body after being installed on the vehicle body, the upper bracket 2 is integrally configured as a plate-shaped structure. At the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com