Expansion joint with steel aluminum composite rails and double copper rings

A steel-aluminum composite and expansion joint technology, which is applied to power rails and other directions, can solve the problems of insufficient reliability and large initial sliding starting force, and achieve the effects of improving the current receiving performance, reducing the number and reducing the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below the present invention is further described in conjunction with the embodiment in the accompanying drawings:

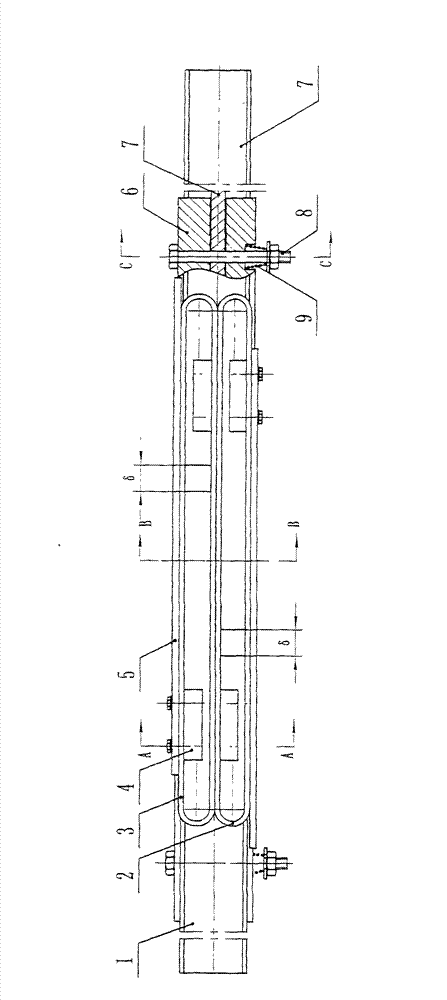

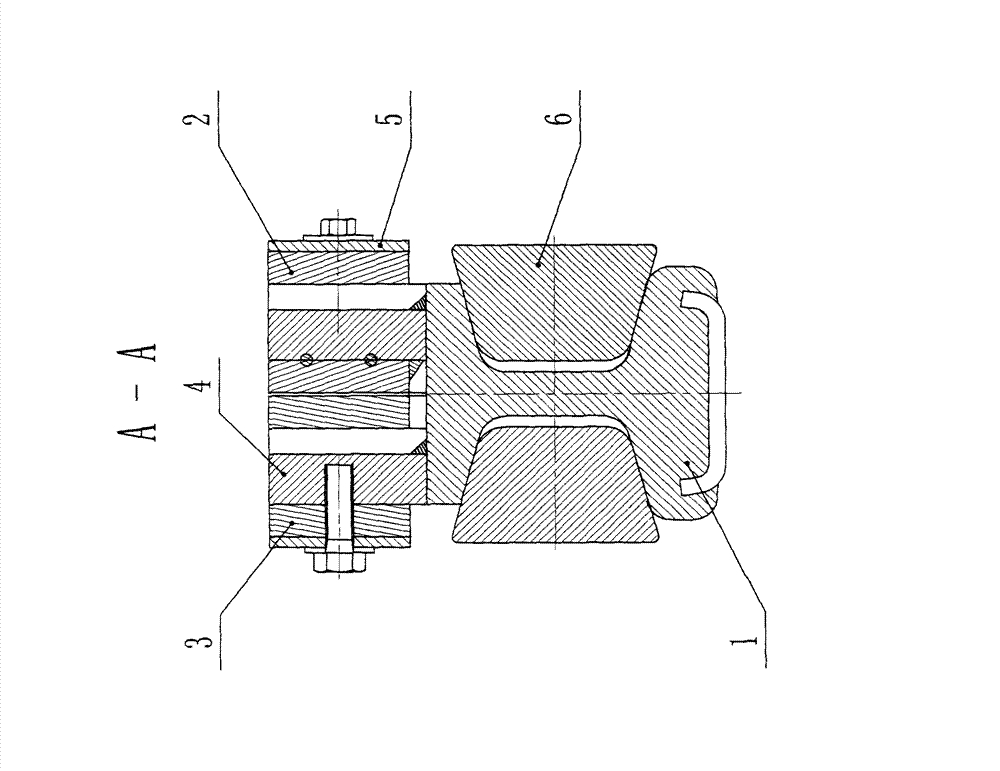

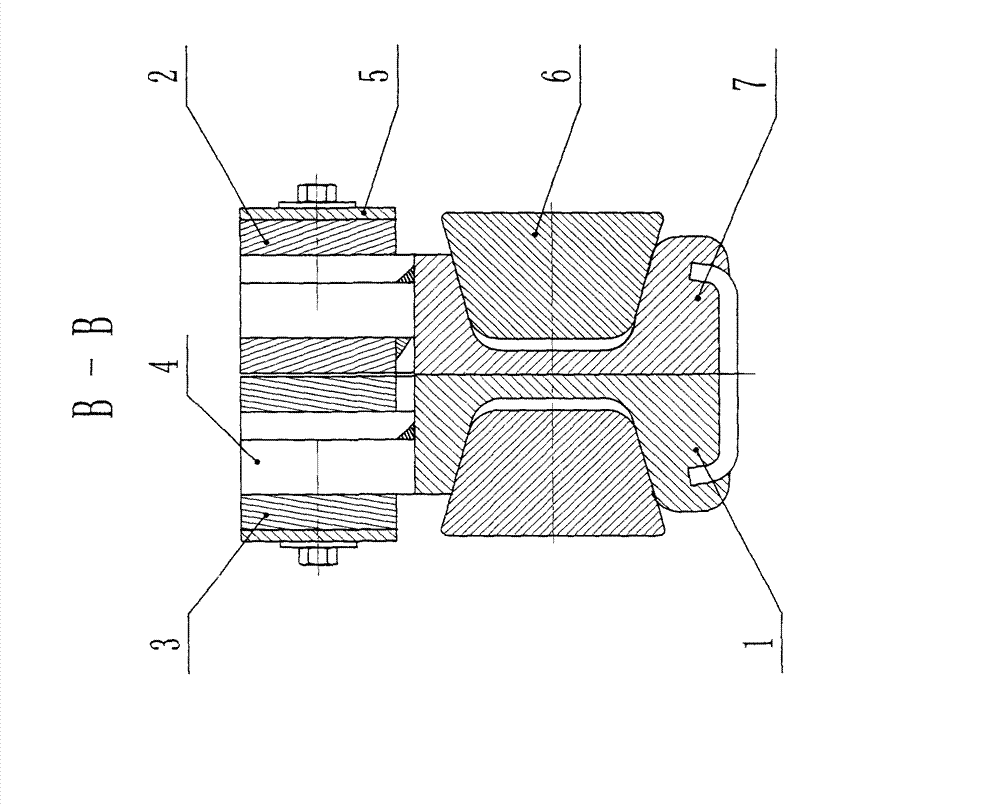

[0015] exist figure 1 Among them, the left side is the left steel-aluminum composite rail 1, and the right side is the right steel-aluminum composite rail 7. The left and right steel-aluminum composite rails are originally integrated, and the wire is run on the wire electric discharge machine in a horizontal Z shape. The length of the slit along the longitudinal center line is 400mm, and the left slit starts from the longitudinal center line and cuts down to the edge. The length of the slots is half of the width of the steel-aluminum composite rail which is 92mm, that is, 46mm; the slots on the right side are cut 46mm upwards from the longitudinal center line, and the three slots make a steel-aluminum composite rail into two sections, which protrude left and right in the middle 400mm. Drag the distance δ to the two ends to become the reserved expansion j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com