Flexible hinge with double-direction variable rigidity

A flexible hinge and stiffness technology, applied in the field of service robots, can solve problems such as increased control difficulty and complex structure, and achieve the effect of improving self-adjustment ability and smooth walking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with accompanying drawing.

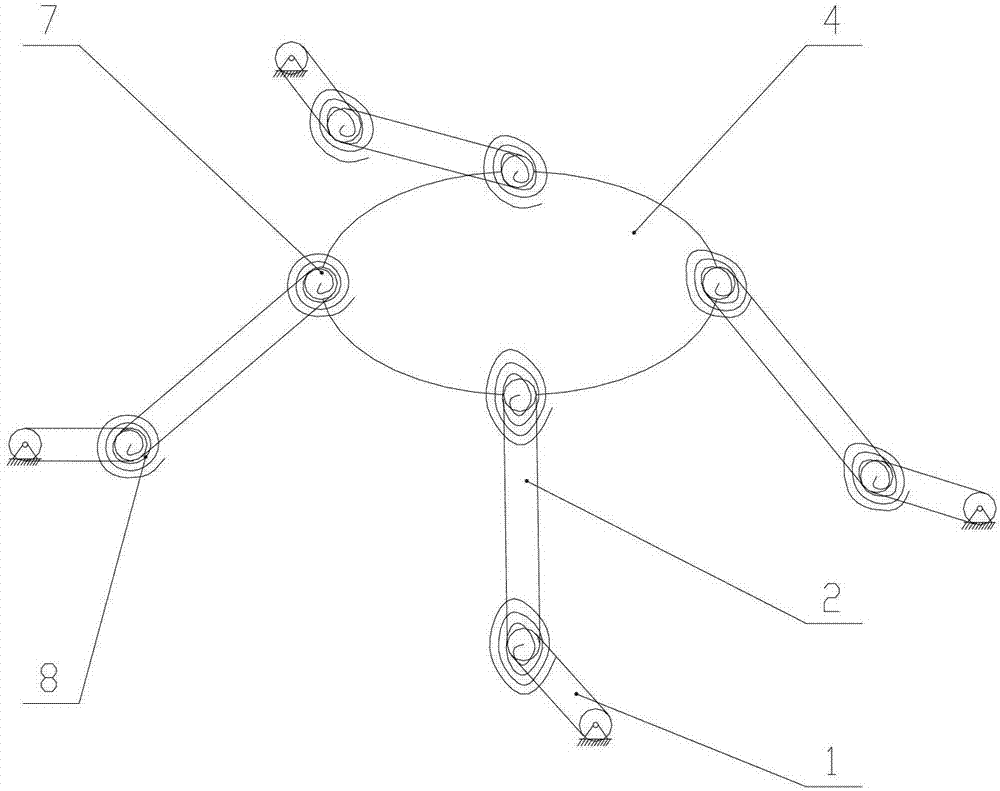

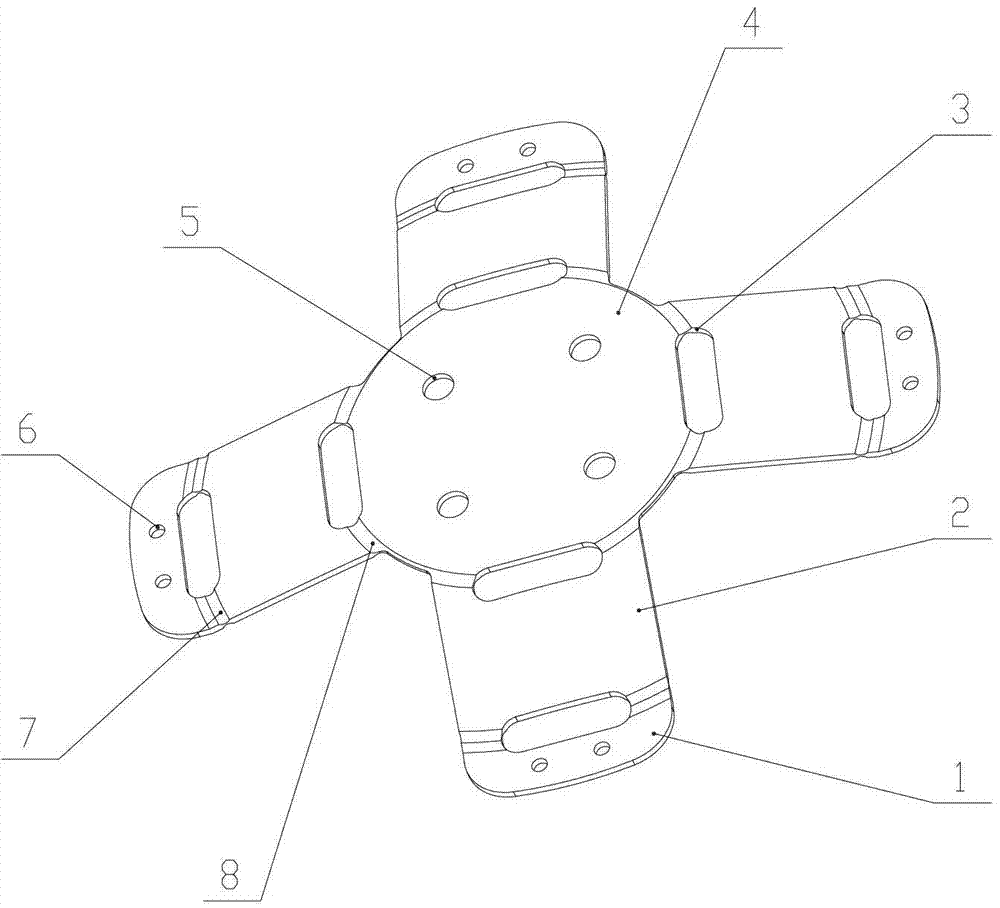

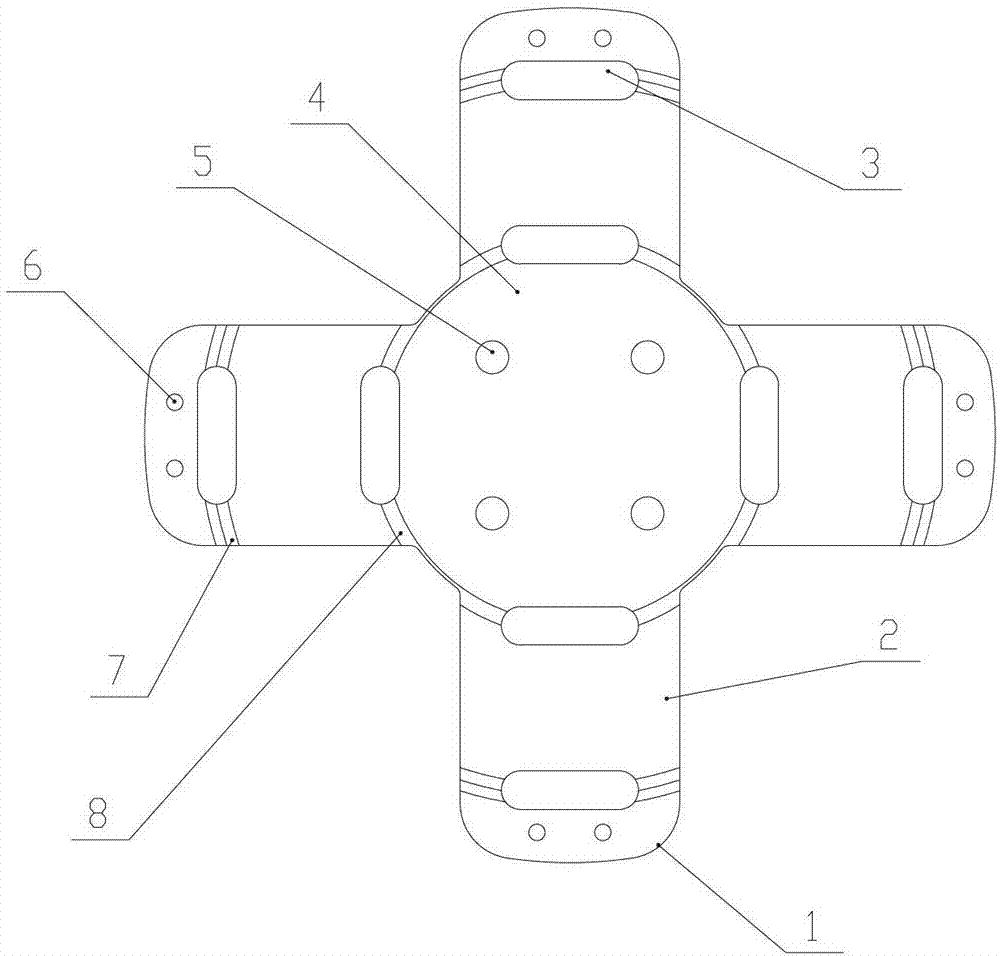

[0016] like figure 1 and figure 2 As shown, the present invention is made up of disc 4 and four flexible supporting units, and four flexible supporting units are evenly distributed along the circumferential direction of disc 4, constitutes a parallel mechanism; Each flexible supporting unit comprises support plate 1, flexible connecting rod 7. The connecting plate 2 and the flexible connecting rod 8, there is a flexible connecting rod 7 between the support plate 1 and the connecting plate 2, and there is a flexible connecting rod 8 between the connecting plate 2 and the disc 4.

[0017] The working process of the present invention is as follows, the flexible hinge is fixed on the sole plate of the robot through the fixing hole 6 on the support plate 1, and the ankle joint support seat is connected with the whole flexible hinge through the connecting hole 5 on the disc 4; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com