Long-distance belt conveyor roller fault detecting device

A belt conveyor, fault detection technology, applied in the direction of conveyor control device, conveyor objects, transportation and packaging, etc., to achieve the effect of easy and fast positioning, high reliability and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in more detail below in conjunction with the accompanying drawings.

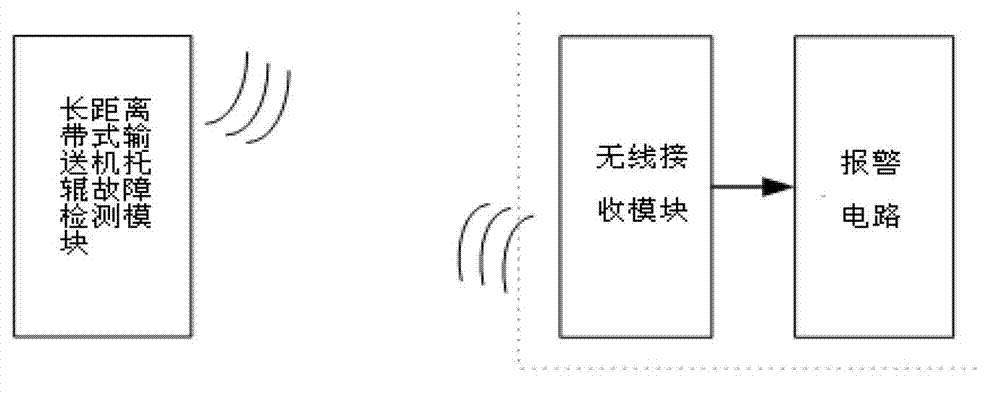

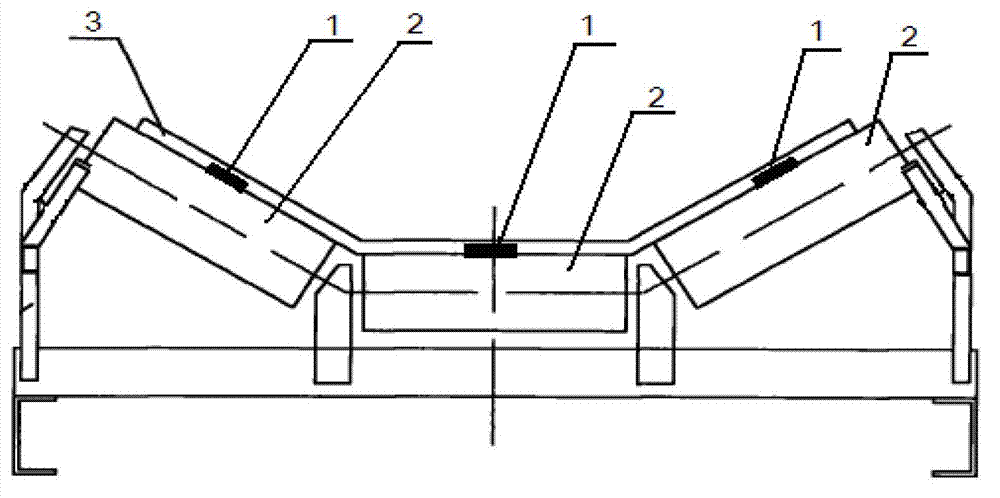

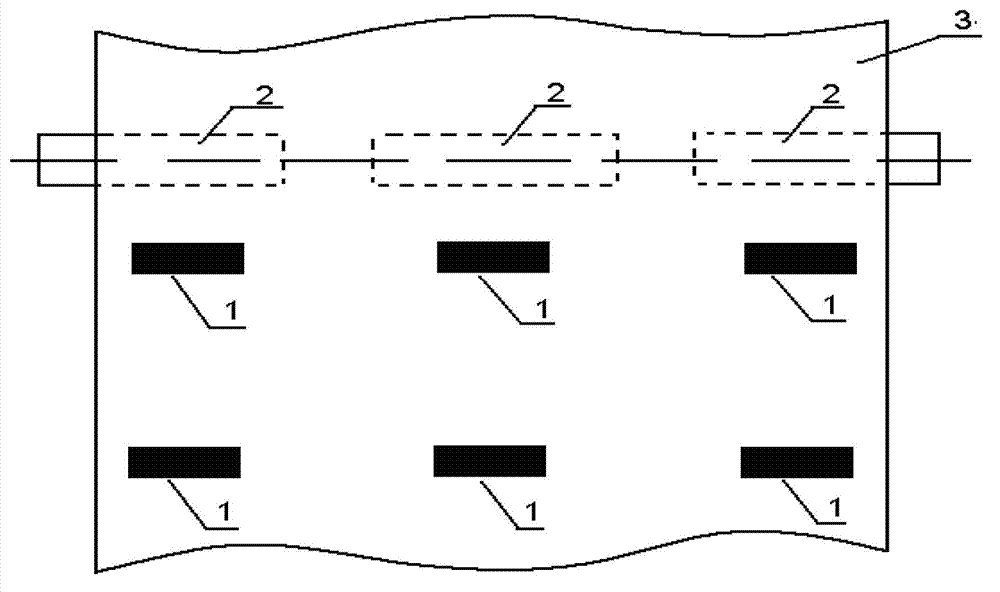

[0035] Such as figure 1 As shown, a long-distance belt conveyor idler fault detection device is composed of a fault detection module, a wireless receiving module and an alarm output circuit. The fault detection module is connected to the wireless receiving module for wireless signals, and the wireless receiving module is wired to the alarm circuit. . Such as figure 2 , image 3 As shown, each fault detection module 1 is a group of two, a total of three groups, one group is installed on the conveyor belt 3 corresponding to the horizontal roller 2 of the long-distance belt conveyor, and the other two groups are respectively installed on the long-distance belt conveyor The machine corresponds to the conveyor belt 3 of the two inclined rollers 2, and each group of fault detection modules is installed at intervals of 1 meter along the traveling direction of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com