Hopper device of steel ball sorting machine

A hopper device and sorting machine technology, which is applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of high energy consumption, equipment vibration, overload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

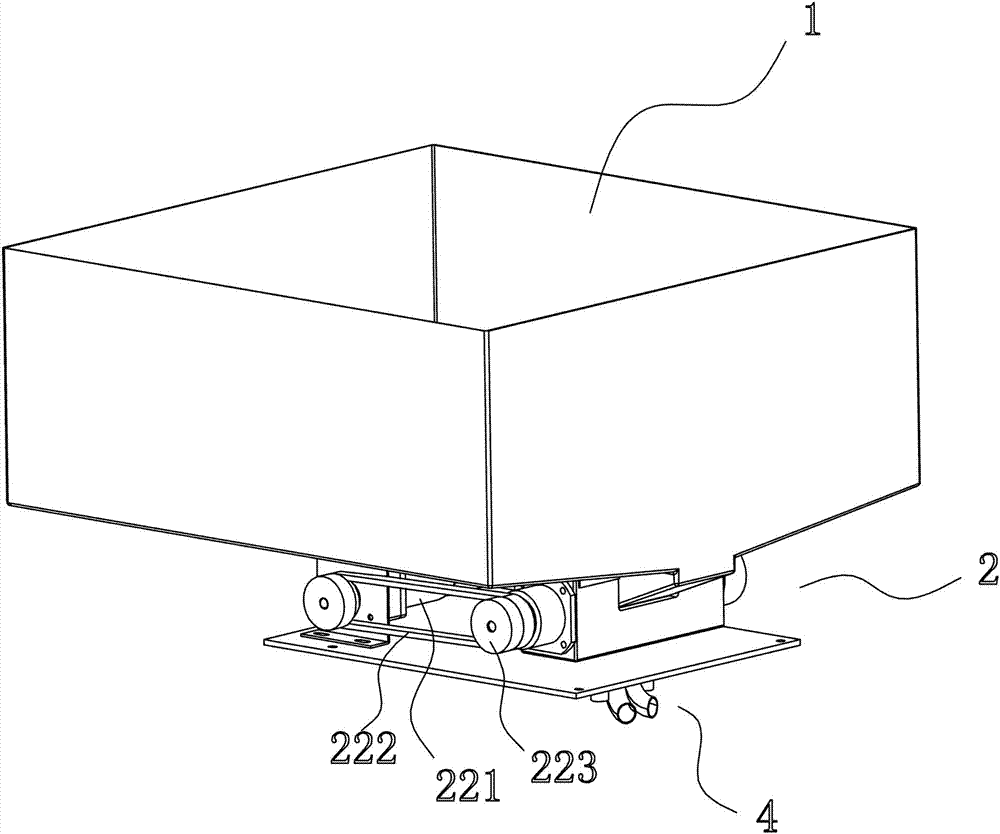

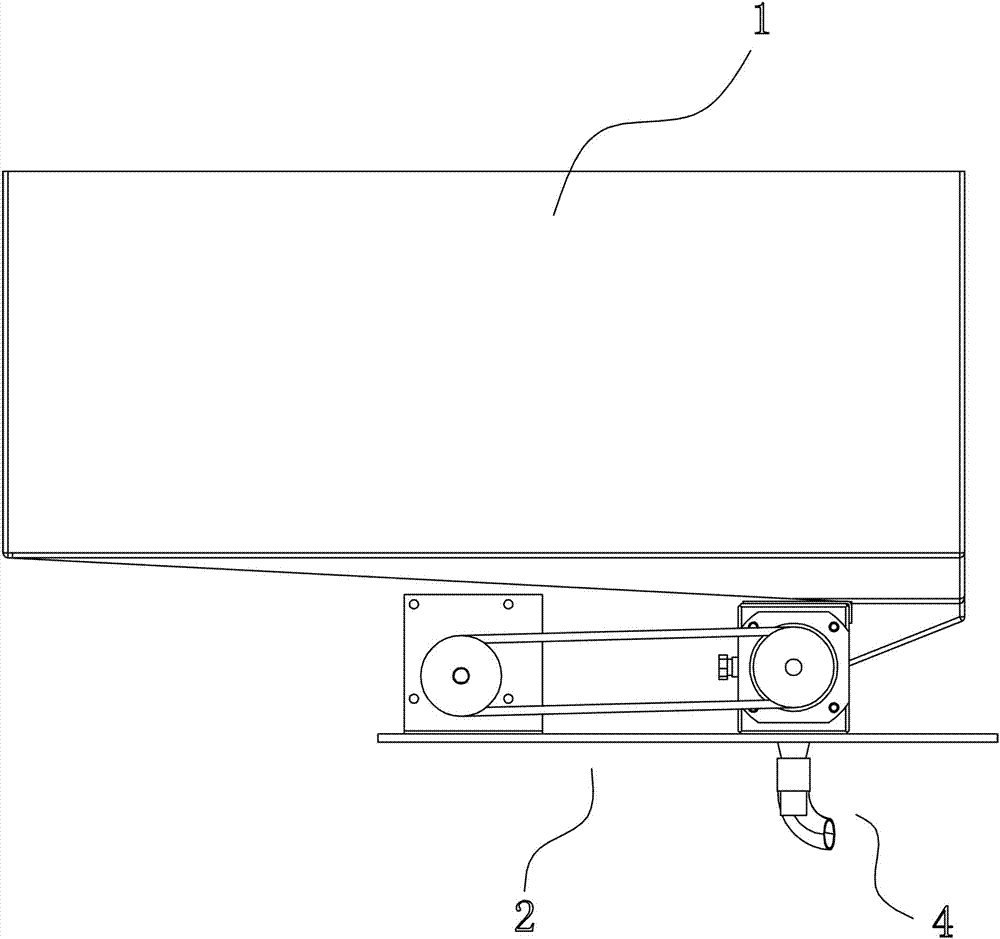

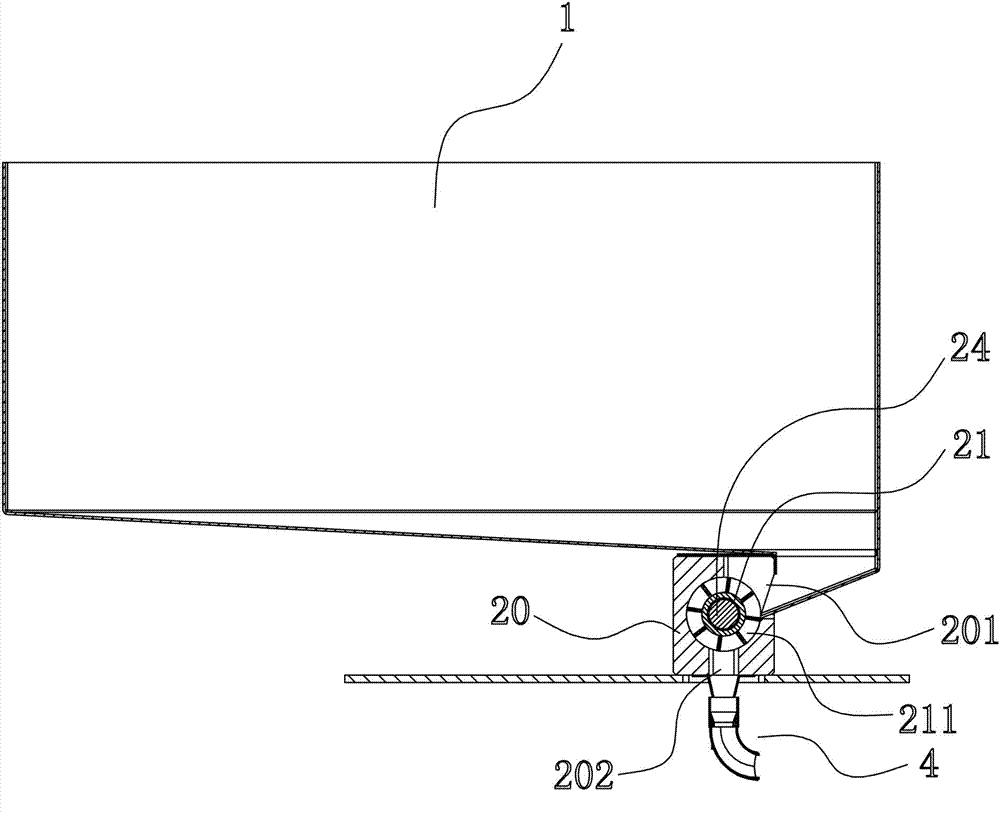

[0029] refer to Figure 1 to Figure 8 , Figure 1 to Figure 8 It is a structural schematic diagram of a specific embodiment of the present invention. As shown in the figure, a hopper device of a steel ball sorting machine is characterized in that it includes a hopper pan 1 and a steel ball distributing device 2 corresponding to the hopper pan 1, wherein the hopper The outlet of the disc 1 is opened on one side of the bottom, and the steel ball distributing device 2 includes a base 20, a distributing cylinder 21 arranged in the base 20, and a driving assembly capable of driving the distributing cylinder 21 to rotate. 1. A reciprocating push assembly that can drive the distributing cylinder 21 to reciprocate. An opening 201 corresponding to the outlet of the hopper tray 1 is provided on the base 20, and a discharge port 202 is provided at the lower end of the base 20. In the discharge port A feeding nozzle assembly 4 corresponding to the steel ball sorting machine is configured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com