Electromagnetic brake

A technology of electromagnetic brakes and brake shoes, which is applied in the direction of brake actuators, gear transmission mechanisms, hoisting devices, etc., and can solve problems such as affecting life, high processing accuracy requirements, and elevator safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

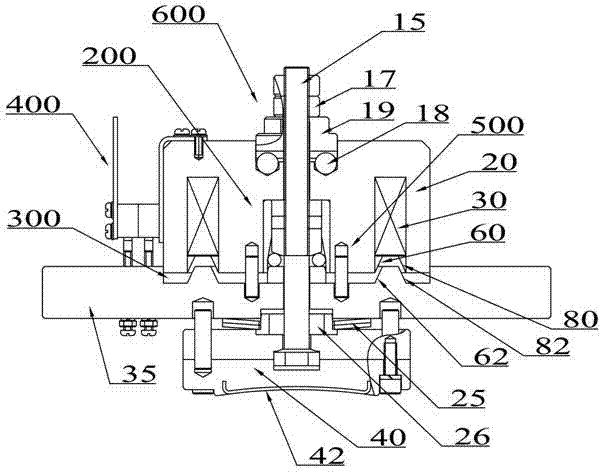

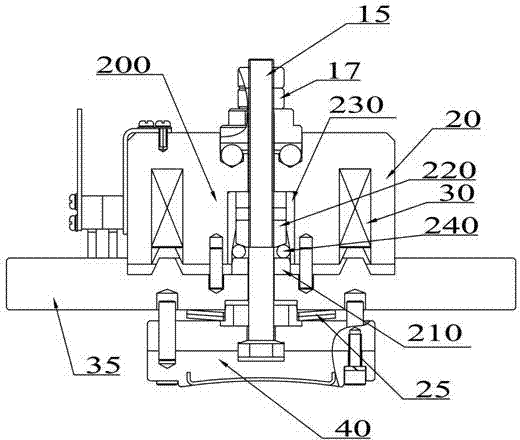

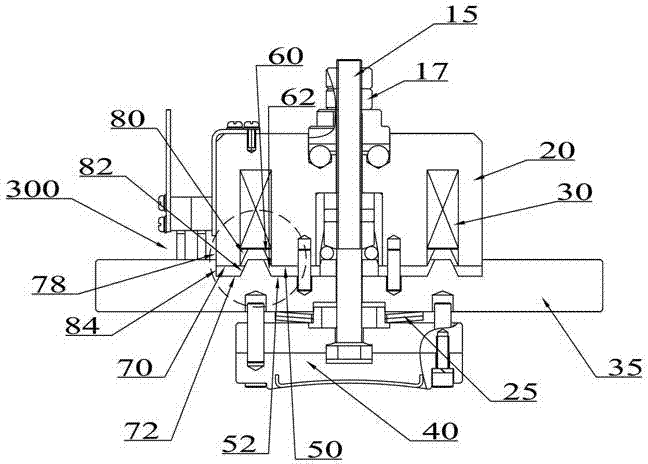

[0056] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0057] see figure 1 , the electromagnetic brake in this embodiment includes a yoke 20, an electromagnetic coil 30 arranged in the yoke 20, an armature 35, a reset elastic member 25, a brake shoe 40, an inclined surface booster mechanism 200, and an end structure of a disc proportional electromagnet 300 , electromagnetic coil series-parallel switching circuit 400 , pin positioning and air resistance buffer device 500 , and manual opening device 600 .

[0058] The fastening bolt 15 runs through the yoke 20 , a manual opening device 600 is provided between one end of the fastening bolt 15 and the yoke 20 , and the other end of the fastening bolt 15 passes through the armature 35 and is fixedly connected with the brake shoe 40 .

[0059] see Figure 18 The manual opening device 600 includes a ball 18, a driving slope 19, a fastening nut 17, and a lock nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com