Roller combined device for full automatic double machine head 2.5 flat knitting machine

A technology for knitting flat knitting machines and combined devices, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of increased production costs, large material waste, and impact on flat knitting machines, so as to save materials, improve economic benefits, and structure well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

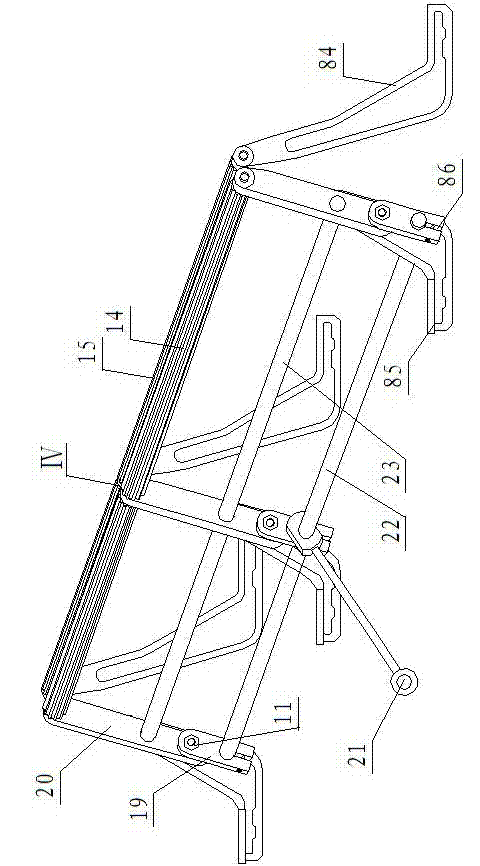

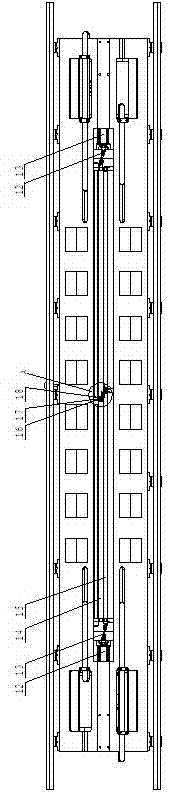

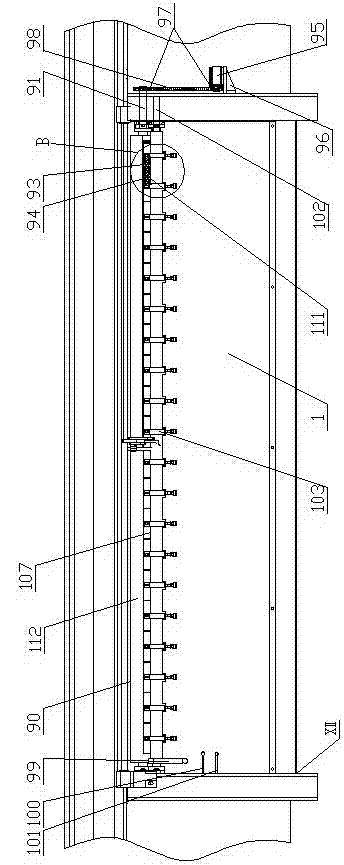

[0028] see Figure 1 to Figure 9 , the present embodiment includes main roller device IV and auxiliary roller device XII, and said main roller device IV includes two fixed roller rods 15, two adjusting roller rods 14, No. 1 support frame 84, No. 2 support frame 85, three One connecting plate 20, three connecting plates 19, fixed shaft 23, rotating shaft 22, adjusting handle 21 and two No. 1 motors 12, one end of two fixed roller bars 15 are connected to each other and connected with No. 1 support frame 84, The other end is connected with No. 1 support frame 84; one end of the two adjusting rollers 14 is connected to each other and connected to a connecting plate 20, and the other end is respectively connected to the other two connecting plates 20; the fixed shaft 23 passes through three The connecting plate 20, the two ends of the fixed shaft 23 are installed on the No. 2 support frame 85; the described rotating shaft 22 passes through the No. 2 support frame 85, and the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com