Mounting pressure test mechanism used for ball grid array (BGA) repair work

A pressure test and work technology, applied in the direction of measuring force, measuring device, instrument, etc., can solve problems such as excessive mounting pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

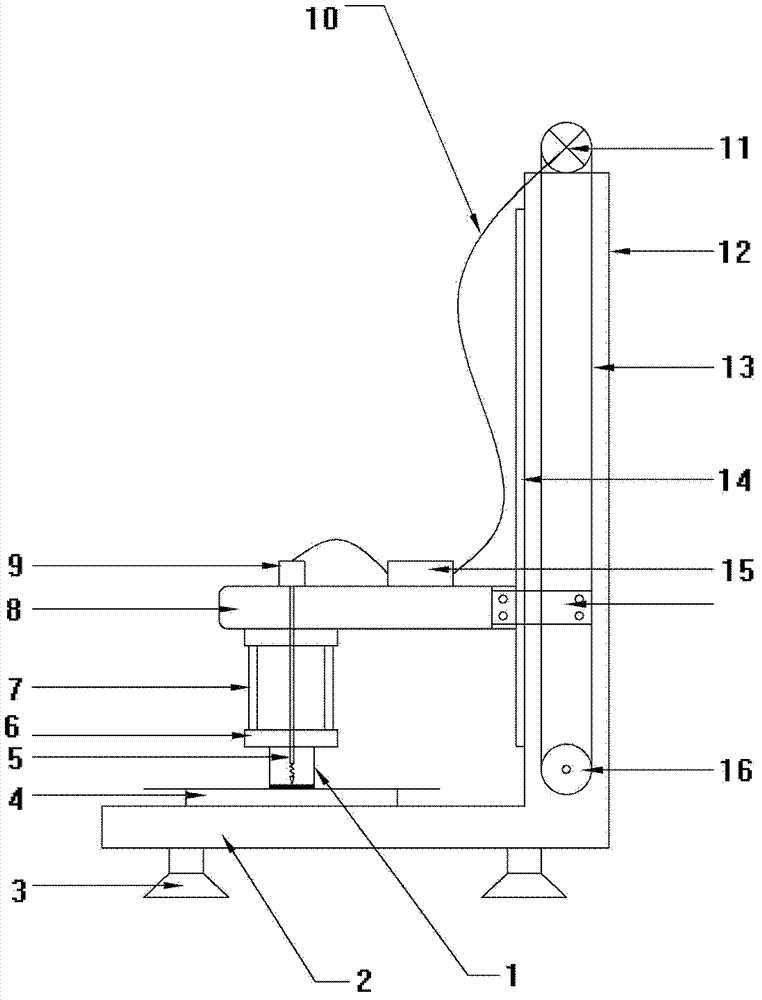

[0010] As shown in the drawings, the present invention is a mounting pressure testing mechanism for BGA rework, including a base 2, and a guide rail mounting frame 12 that forms an integral structure with the base 2, and the rail mounting frame 12 is provided with a timing belt 13 and a slide Rail 14, the upper end of synchronous belt 13 is connected with stepping motor 11, the lower end passes through pulley 16, PCB board fixing mechanism 4 is arranged on the base 2, and the sliding mounting bracket 8 is vertically installed on the sliding rail 14, and is connected with synchronous belt 13 , the pressure sensor 9 and the stepper motor controller 15 are installed on the top of the sliding mounting frame 8, and the pressure sensor 9, the stepper motor controller 15 and the stepper motor 11 are connected by wires 10, the BGA welding probe 6, the pressure detection The rod 5 and the hot air nozzle 1 are installed on the lower part of the sliding mounting frame 8 through the connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com