Calculation method of load distribution of male mold system based on large wind power blades

A wind power generation blade and load distribution technology, which is applied in the direction of calculation, electrical digital data processing, special data processing applications, etc., can solve the problems of irregular load distribution of large wind power blade male mold system and irregular blade load distribution, etc. Achieve the effects of high precision, simple calculation, and guaranteed calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

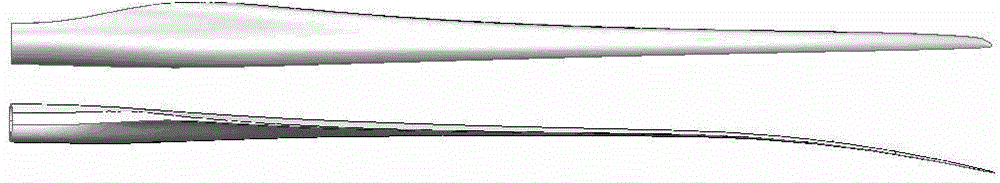

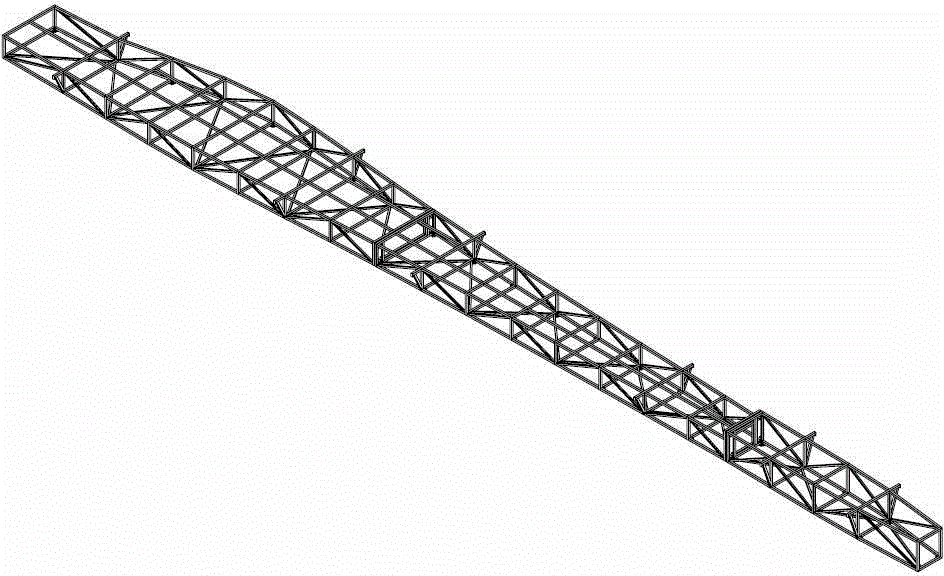

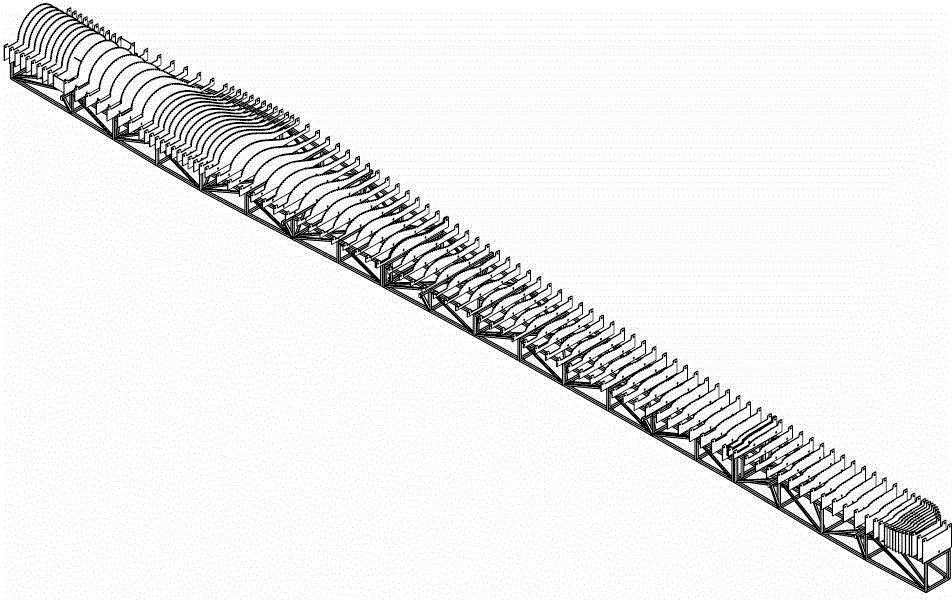

[0035] like Figure 1-Figure 5 As shown, the male mold system is composed of a glass shell substitute wood layer 1, a glass shell glass fiber reinforced plastic layer 2, a glass shell square steel layer 3, a cross-section wire-cut steel plate 4 and a conformal support steel frame 5 to form a cross-section wire-cut steel plate, wherein: The conformal support steel frame 5 is placed on the ground, and the steel plate 4 is cut along the specified distance welding section line on the conformal support steel frame 5, and then the glass shell square steel layer 3 and the glass shell glass fiber reinforced plastic layer 2 are sequentially laid on the cross section line cut steel plate 4 and glass shell substitute wood layer 1; Figure 12 As shown, the specific steps are as follows:

[0036] (1) Calculation of load distribution of supporting steel frame. Use APDL of ANSYS to establish a random finite element model, and after setting the gravity, the software itself calculates the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com