Electrode, nonaqueous electrolyte battery, and battery pack

A non-aqueous electrolyte and electrode technology, which is applied to large-size batteries/battery packs, small-size batteries/battery packs, battery electrodes, etc., can solve problems such as low energy density, and achieve the effect of improving input and output characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

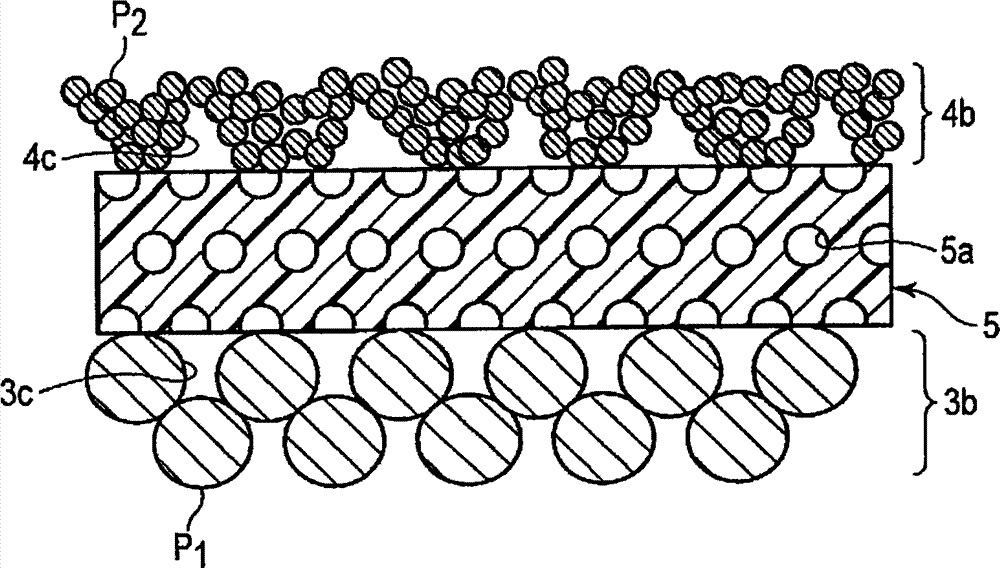

[0025] According to the first embodiment, there is provided an electrode including a current collector and an active material-containing layer formed on the current collector. The active material-containing layer may be formed on one or both surfaces of the current collector. The Li intercalation potential of the active material contained in the active material layer is 0.4V (vs.Li / Li + )above. In the pore size distribution measured by mercury porosimetry, there are a first peak having a mode diameter of 0.01 μm to 0.1 μm and a second peak having a mode diameter of more than 0.2 μm and 1 μm or less. The volume of the pores measured by the mercury porosimetry is 0.1 mL to 0.3 mL per 1 g of the electrode weight (the weight excluding the current collector).

[0026] The reason for setting the Li intercalation potential of the active material within the above range will be described. For a ratio of 0.4V (vs.Li / Li + ) Active materials (such as graphite, lithium metal, etc.) tha...

no. 2 Embodiment approach

[0052] According to the second embodiment, it is possible to provide a nonaqueous electrolyte battery including a positive electrode, the electrode of the first embodiment as a negative electrode, and a nonaqueous electrolyte.

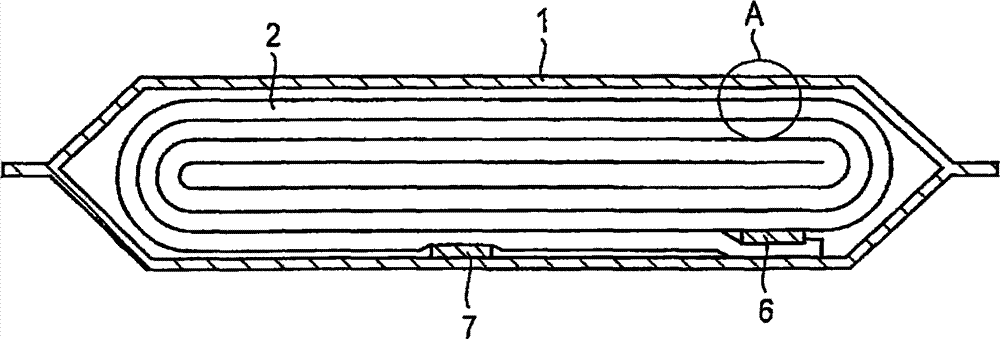

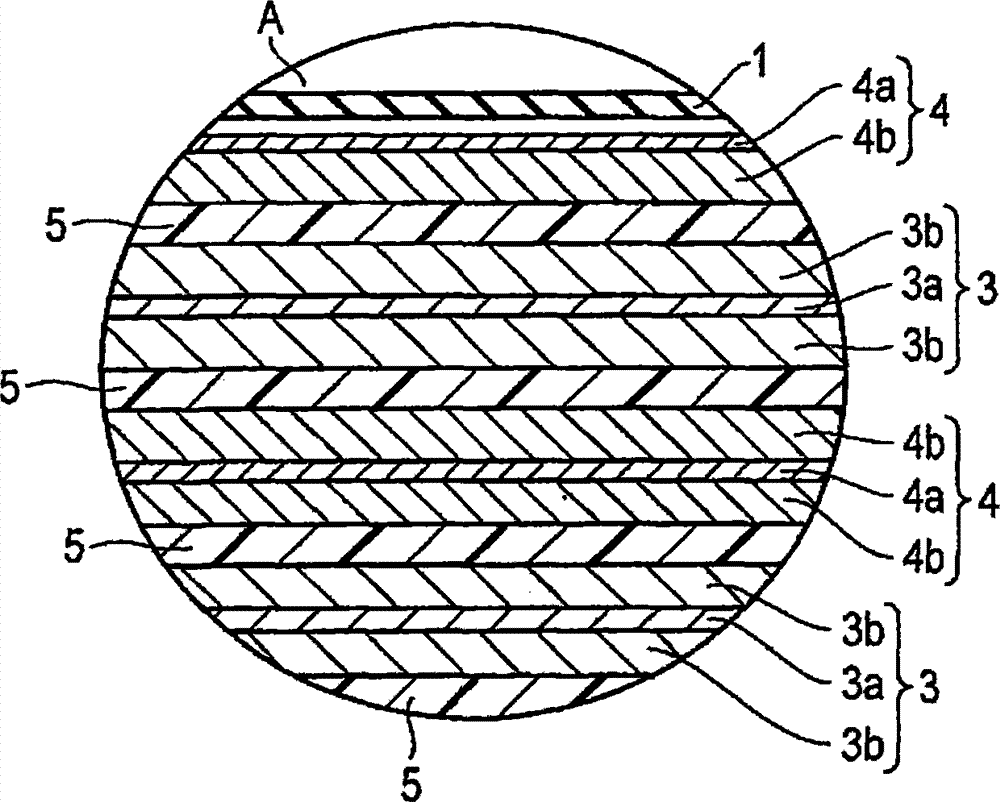

[0053] For an example of the non-aqueous electrolyte battery of the second embodiment, refer to Figure 1 to Figure 3 Detailed description. figure 1 It is a sectional view showing an example of the non-aqueous electrolyte battery of the second embodiment, that is, a flat lithium-ion secondary battery, figure 2 yes means figure 1 An enlarged cross-sectional view of part A of, image 3 yes means figure 1 A schematic diagram of the vicinity of the boundary of the secondary battery containing the positive electrode active material layer, the porous separator, and the layer containing the negative electrode active material.

[0054] Such as figure 1 As shown, for example, an electrode group 2 is accommodated in an exterior member 1 made of a film. Th...

no. 3 Embodiment approach

[0107] The battery pack of the third embodiment includes one or more nonaqueous electrolyte batteries of the second embodiment. Preferably, the non-aqueous electrolyte battery of the second embodiment is used as a unit cell, and the unit cells are electrically connected in series or in parallel to form a battery pack.

[0108] The non-aqueous electrolyte battery of the second embodiment is suitable for being assembled into a battery pack, and the battery pack of the third embodiment has excellent cycle characteristics. Explain this.

[0109] When the retention of the non-aqueous electrolyte is improved, the entire surface of the negative electrode active material can be brought into contact with the non-aqueous electrolyte, and the lithium ion concentration in the negative electrode active material can be easily made uniform. As a result, application of an overvoltage becomes difficult, that is, since local overcharge and overdischarge are less likely to occur, the utilizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com