Tobacco leaf slitting method based on chemical component distribution rule

A technology of chemical composition and distribution rules, which is applied in the fields of tobacco, tobacco processing, food science, etc., can solve the problems of not determining the cutting method of tobacco leaves, etc., so as to broaden the scope of use, increase the ratio of slices and long stems, and increase the value of use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] 1) Sample processing

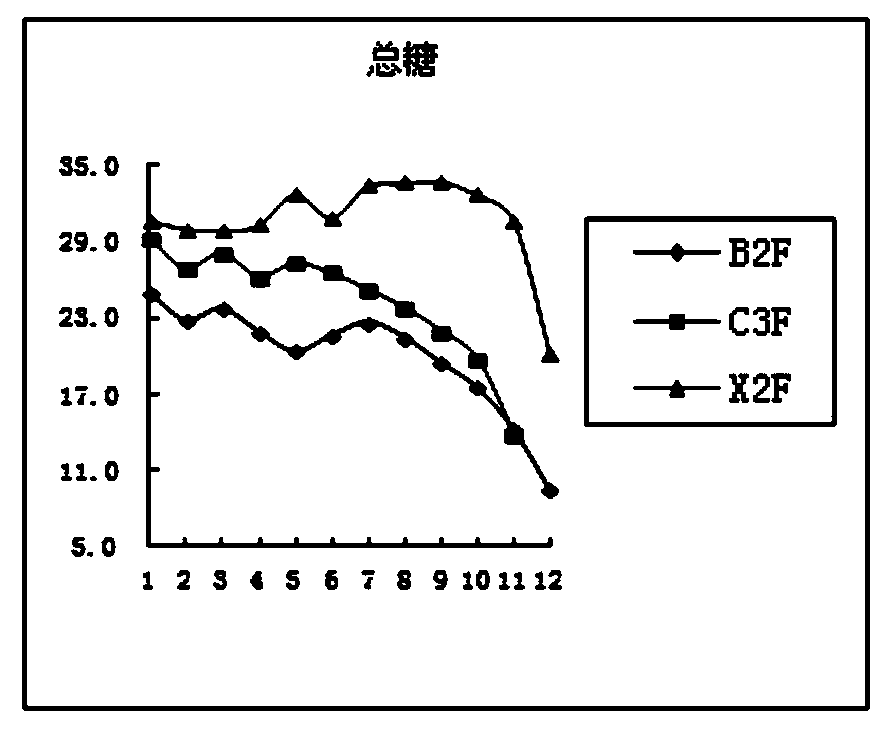

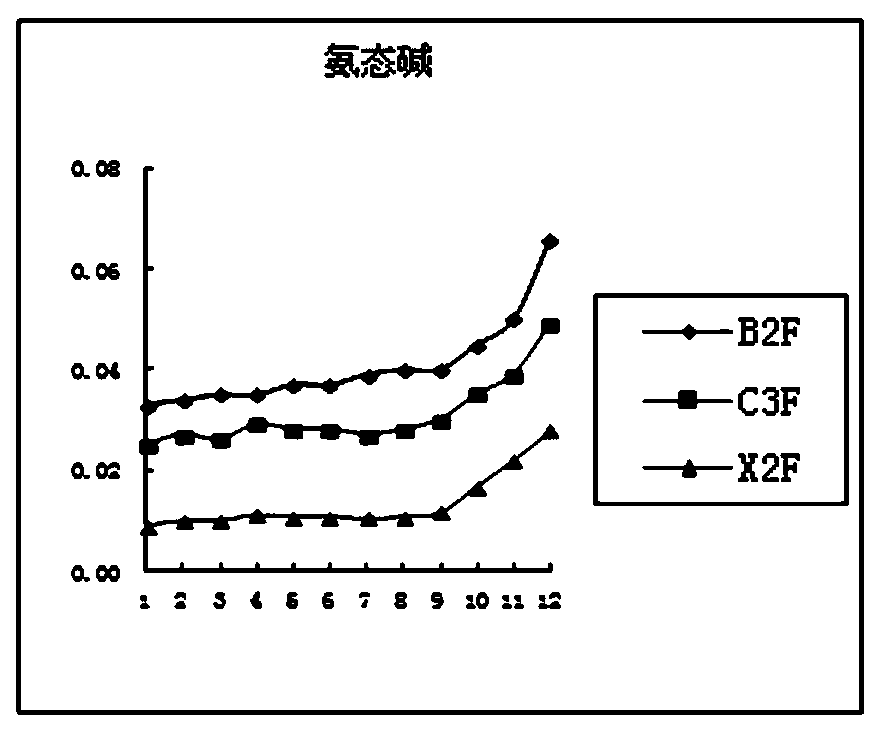

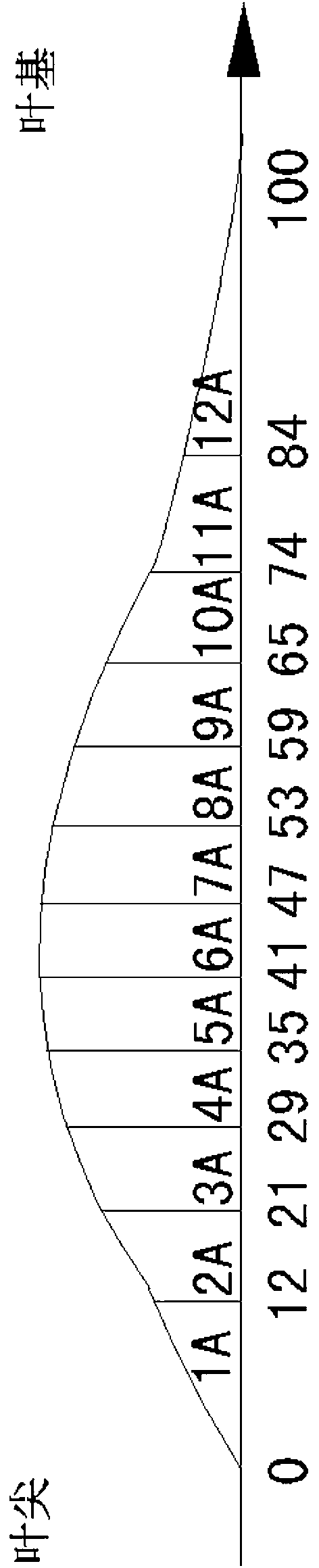

[0056] According to the national standard (GB2635-92), select 10 complete leaves of the first-cured tobacco leaves of the upper, middle and lower parts of the 2011 Kunming Hongda variety (B2F, C3F, X2F), and remove the stems. figure 1 The method is longitudinal equal-area slitting, and the number below the coordinate axis is the percentage of each slitting point from the leaf tip to the leaf base to the length of the tobacco leaf. The above-mentioned 36 samples were cut into shreds respectively, dried appropriately, pulverized, passed through a 40-mesh sieve, and stored in sealed bags for testing.

[0057] 2) Chemical composition test

[0058] According to the standard test method of the tobacco industry, the total sugar, reducing sugar, nicotine, total nitrogen, ammoniacal alkali, and chlorine content of the above samples were measured by a continuous flow analyzer, and the potassium content of the tobacco leaf sample was determined by flame pho...

Embodiment 2

[0066] 1) Sample pretreatment

[0067] According to the national standard (GB2635-92), select 10 complete leaves of the 2011 Yuxi K326 variety B2F grade first-cured tobacco leaves, remove the stems, and press each half piece figure 1 The method is to cut into 12 segments of equal area in the longitudinal direction, collect the tobacco leaves of the same segment respectively and cut them into shreds, dry them properly, grind them, and pass through a 40-mesh sieve, then put them in sealed bags and store them for testing.

[0068] 2) Near-infrared spectrum collection

[0069] Under the conditions of ambient temperature 25°C and stable relative humidity, a certain amount of tobacco powder samples were packed into sample cups to ensure that the samples were loaded with the same tightness and thickness, and then their near-infrared spectra were measured with a near-infrared spectrometer. The spectral scanning range is 10000-4000cm-1, the number of scanning times is 64, and the reso...

Embodiment 3

[0076] 1) Sample pretreatment

[0077] According to the national standard (GB2635-92), 10 complete leaves of first-cured tobacco leaves of three grades (B2F, C3F, X2F) of the upper, middle and lower parts of the 2011 Kunming Hongda variety were selected; figure 1 The method is longitudinally equal-area slitting. The above-mentioned 36 samples were cut into shreds respectively, dried appropriately, pulverized, passed through a 40-mesh sieve, and stored in sealed bags for testing.

[0078] 2) Chemical composition test

[0079] According to the standard test method of the tobacco industry, the continuous flow analyzer measures the total sugar, reducing sugar, nicotine, total nitrogen, and ammoniacal alkali of the above samples, and uses the flame photometry to measure the potassium content of the tobacco leaf sample. Some of the test results were simply calculated to obtain protein, nicotine nitrogen, total volatile alkali, Shimuke value, nitrogen-alkali ratio, sugar-alkaline r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com