Lightweight concrete and preparation method and applications thereof

The technology of lightweight concrete and lightweight aggregate is applied in the field of lightweight concrete and its preparation, and can solve the problems of inability to meet the requirements of high tensile strength of concrete blocks, unattainable flexural-compression ratio, and low tensile strength, etc. Achieve the effect of light weight, improved seismic performance, and improved flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

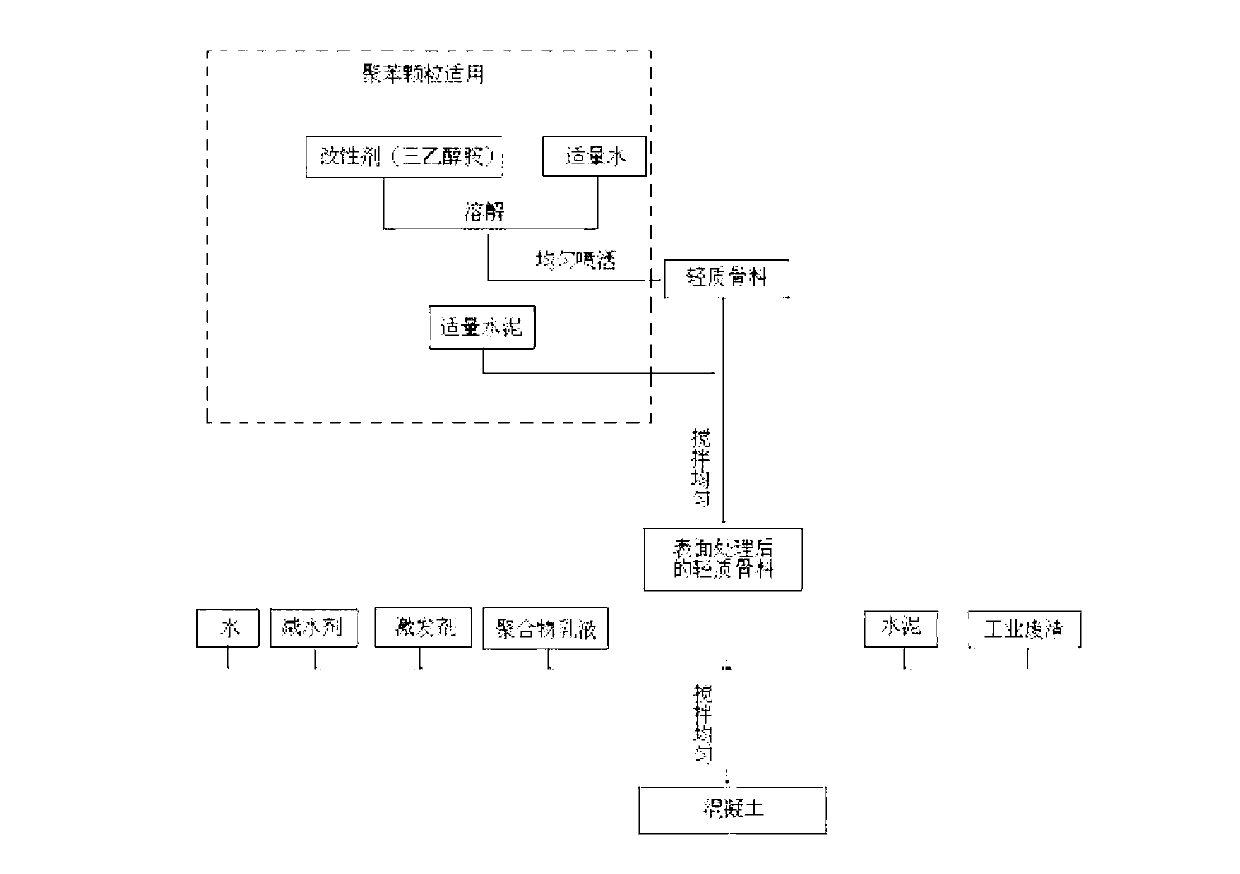

[0033] A lightweight concrete, which is composed of the following raw materials, in terms of parts by weight: 50 parts of cement, 25 parts of fly ash, 25 parts of slag powder, 2 parts of naphthalene-based water reducer, 4 parts of sodium sulfate, and 40 parts of water , 0.8 part of polyphenylene particle, 0.3 part of polymer emulsion, described polymer emulsion is taken and mixed by T-31 curing agent and epoxy resin by weight ratio of 1:4; The preparation method of this concrete comprises following step:

[0034] A. Weigh cement, fly ash, slag powder, naphthalene-based water reducer, sodium sulfate, water, polyphenylene particles, polymer emulsion according to the proportion;

[0035] B. carry out surface treatment to the polyphenylene particle that takes by weighing in step A: be dissolved in water with the triethanolamine of polyphenylene particle quality 6% and obtain triethanolamine aqueous solution, with watering can the triethanolamine aqueous solution is evenly sprayed ...

Embodiment 2 Embodiment 6

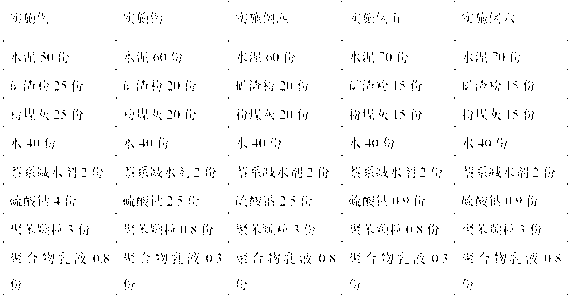

[0037] Embodiment 2-Embodiment 6: A kind of lightweight concrete. Please refer to Table 1 for the raw materials and parts by weight of the lightweight concrete. The preparation method is the same as that of Embodiment 1.

[0038] Table I:

[0039]

Embodiment 7

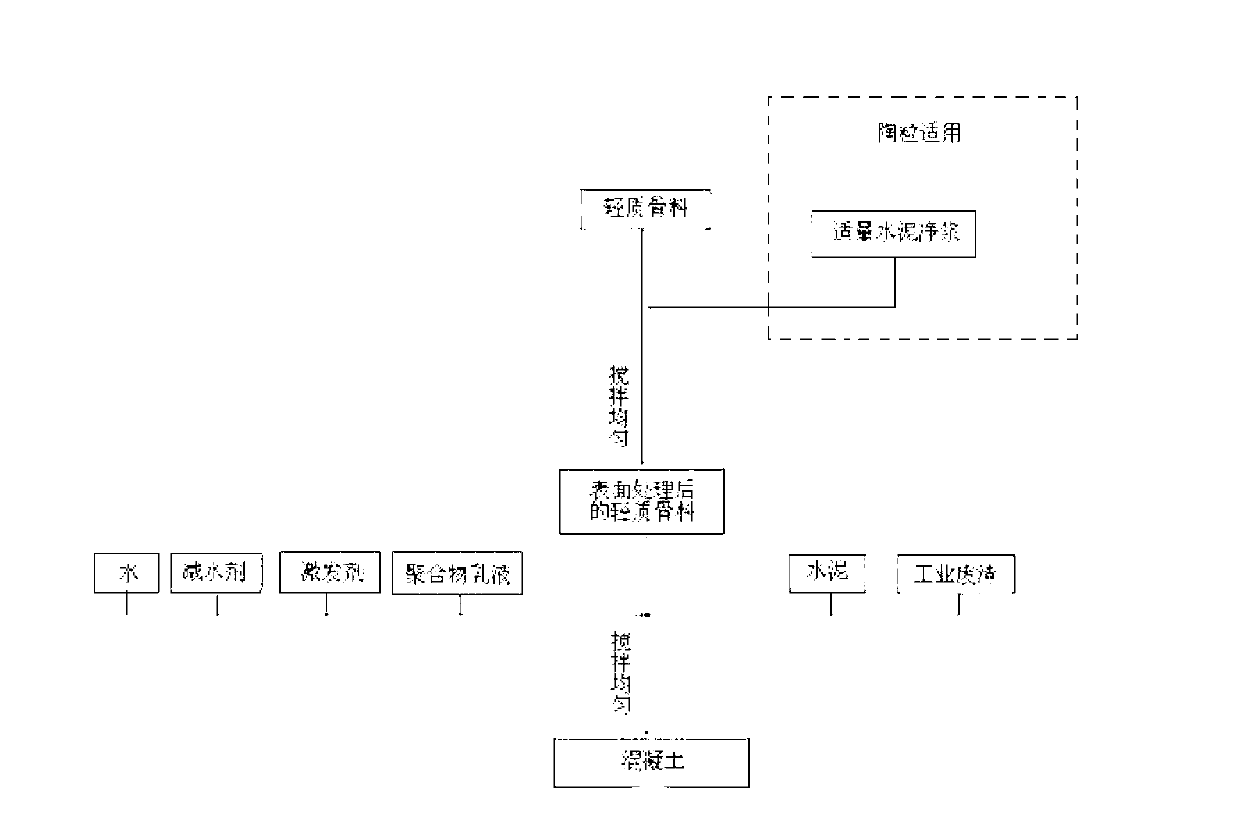

[0041] A lightweight concrete, which is composed of the following raw materials, in terms of parts by weight: 50 parts of cement, 25 parts of slag powder, 25 parts of fly ash, 40 parts of water, 2 parts of naphthalene-based water reducer, 4 parts of sodium silicate part, 10 parts of ceramsite, 0.3 part of polymer emulsion, described polymer emulsion is taken and mixed by weight ratio of 1:4 by T-31 curing agent and epoxy resin; The preparation method of this concrete comprises following steps:

[0042] A. Weigh cement, slag powder, fly ash, water, naphthalene superplasticizer, sodium silicate, ceramsite, polymer emulsion according to the proportion;

[0043] B. Carry out surface treatment to the ceramsite weighed in step A: stir the ceramsite and the cement slurry with a water-cement ratio of 0.4 evenly to complete the shell making. The amount of the cement slurry is such that the ceramsite can be completely wrapped ;

[0044] C. Disperse and dissolve the polymer emulsion, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap