Splicing building board for rapid modeling and template rib, template and template structure

A technology for building boards and boards, which is applied to formwork/template components, building structures, and on-site preparation of building components. Quick and easy, smooth and flat building surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

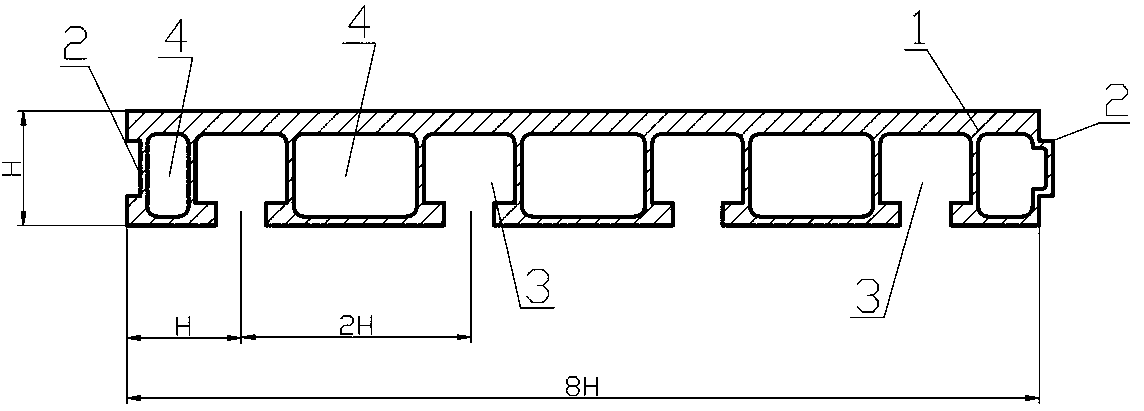

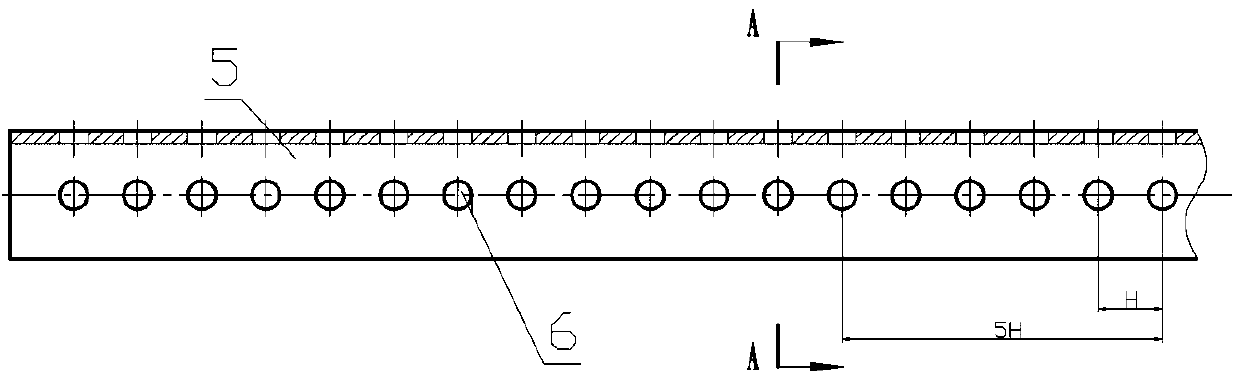

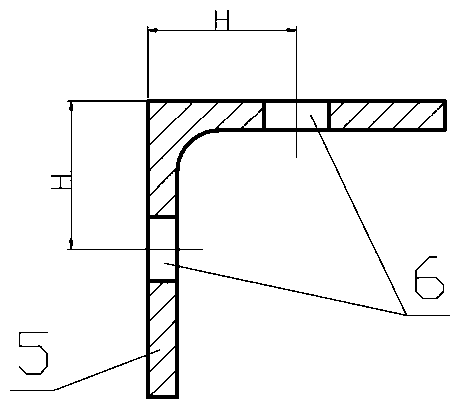

[0057] exist Figure 5 In the shown embodiment, a splicable building board for rapid modeling includes a splicable board 1 made of engineering plastics, the thickness H of the splicable board 1 is 25 mm, and the effective width of the splicable board 1 is equal to 25 mm. 12 times that of 300mm. Coupling and splicing structures 2 are arranged on both sides of the splicable sheet 1 in the width direction for splicing, and the coupling and splicing structures 2 on both sides of the splicable sheet 1 are convex strips, and the convex strips on the splicable sheet 1 are connected to the other After the grooves on the splicable panels are spliced, the convex strips are completely embedded in the grooves. The front of the splicable panels 1 is a smooth plane, and the back of the splicable panels is provided with 3 fixed grooves 3 with an L-shaped cross-section, which can be spliced. The distance between the center line of the first fixing groove 3 on the back of the plate 1 and the ...

Embodiment 3

[0059] exist Figure 6 The illustrated embodiment is basically the same as Embodiment 1, except that the materials of the spliceable panels 1 are different, and the coupling splicing structures 2 and effective widths of the splicable panels 1 of the splicable panels 1 are different.

Embodiment 4

[0061] exist Figure 7 The illustrated embodiment is basically the same as Embodiment 1, except that the effective width of the spliceable board 1 , the structure of the fixing groove, and the coupling splicing structure 2 are different.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com