Machine for chopping and returning rice and wheat straw root stubbles into soil

A technology of rice and wheat straw and root stubble, which is applied in the direction of cutters, harvesters, crop processors, etc., and can solve the problems of poor crushing effect of rice and wheat straw and root stubble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

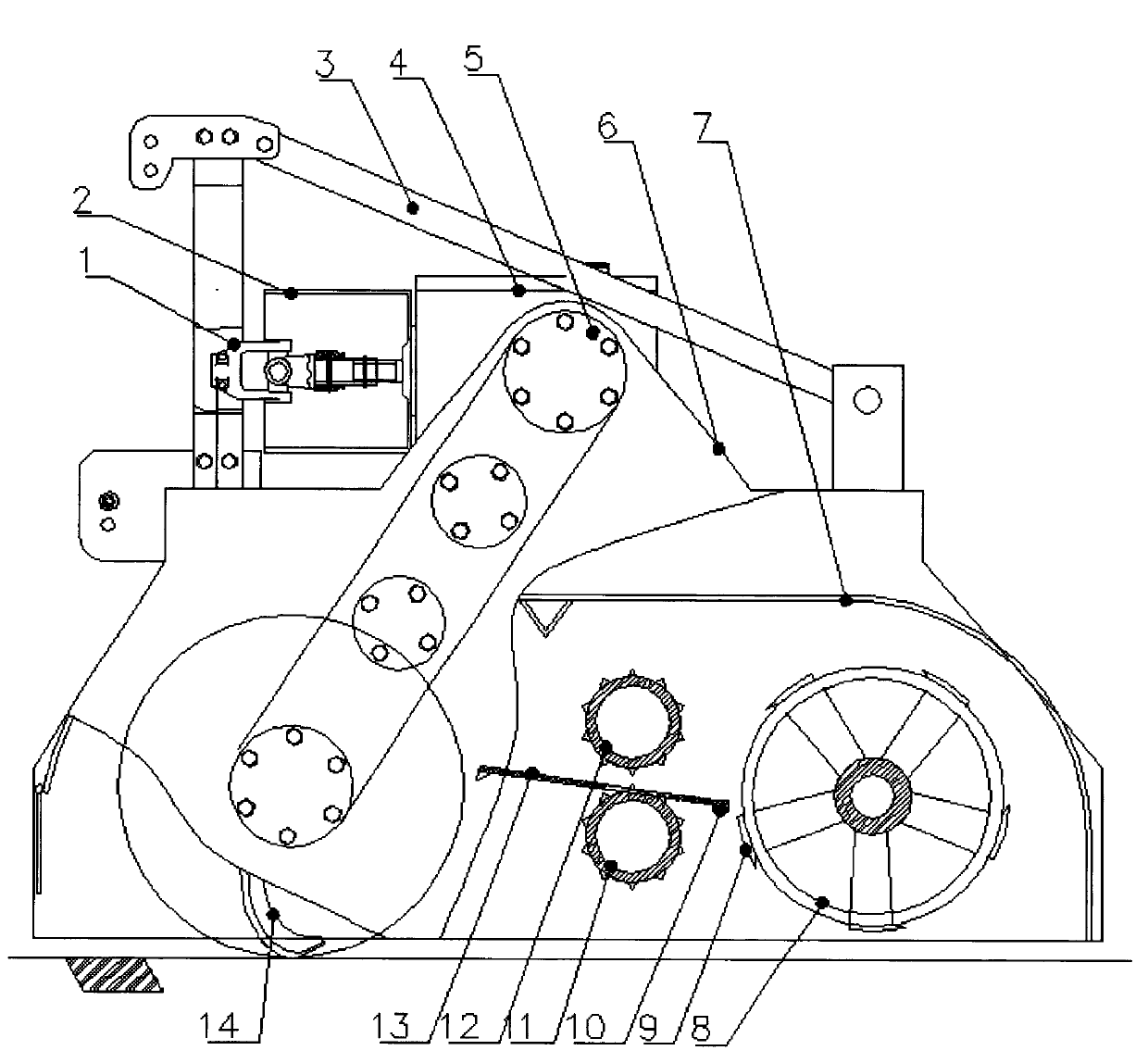

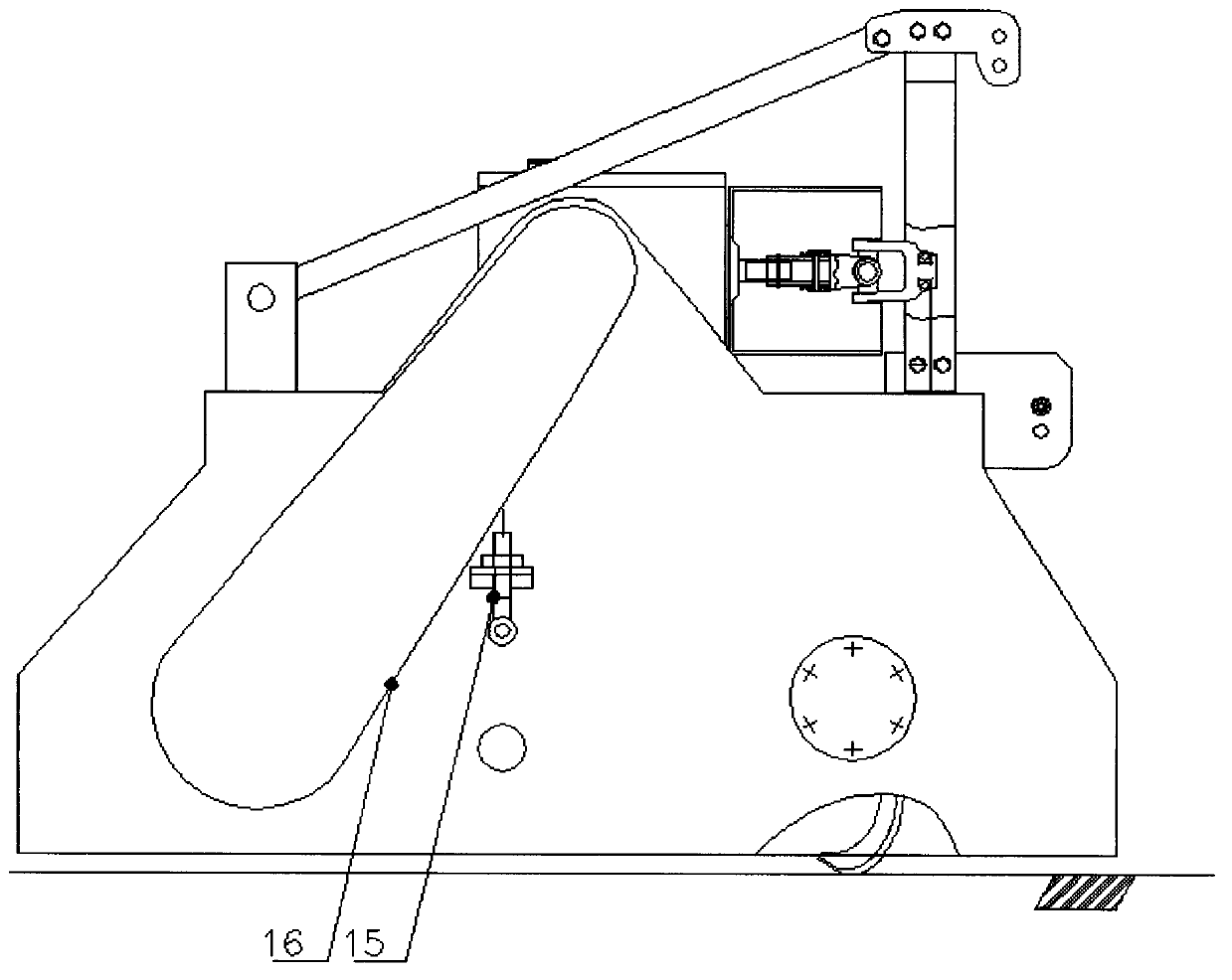

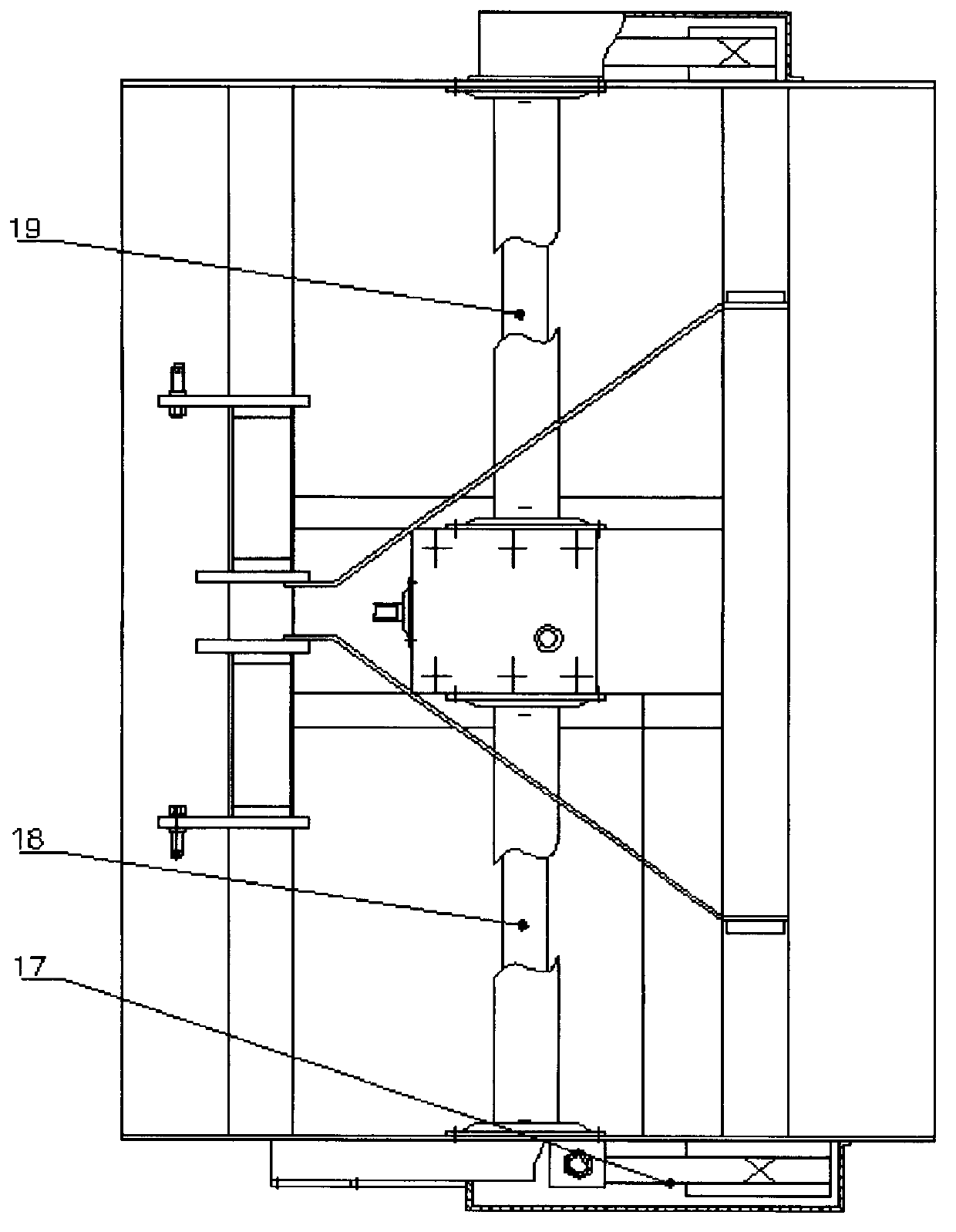

[0015] like figure 1 , 2 As shown in , 3, a rice and wheat straw chopping and returning machine includes a universal joint transmission shaft 1, an input shaft protection cover 2 is arranged on the top of the universal joint transmission shaft 1, and an input shaft protection cover 2 is provided on the top of the input shaft protection cover 2. Suspension frame assembly 3; universal joint transmission shaft 1 is connected with the middle gear box assembly 4, and the middle gear box assembly 4 is connected with the side gear box assembly 5 and the The chopping belt transmission assembly 16 is connected; the side gear box assembly 5 drives the rotary tiller shaft 14 to rotate through the rotating shaft, and side plates 6 are installed on both sides of the rotary tiller shaft 14; the chopping belt drive assembly 16 drives the chopping The cutter shaft assembly 8 rotates, and the casing 7 is installed on the top of the chopping cutter shaft assembly 8; the lower conveying roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com