Material proportioning station

A material and feeding unit technology, which is applied to the occasions where powder materials are mixed in proportion, in the field of small particles, can solve the problems of high operation and maintenance costs, many equipment, large investment, etc., and achieve the effect of small and compact structure and accurate given amount.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

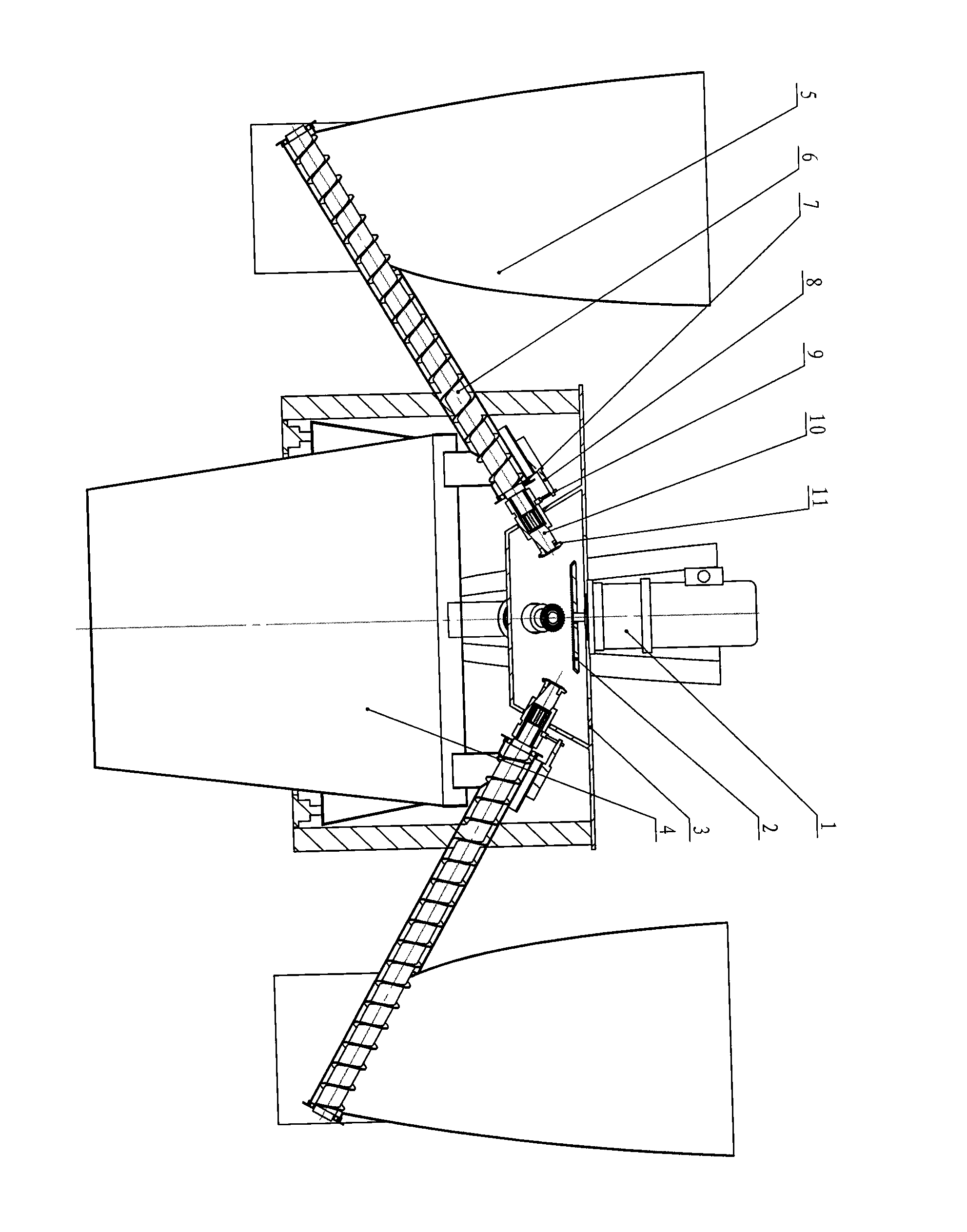

[0015] The reducer (1) drives the central bevel gear (2) to rotate; the conveying screw (6) is fixedly mounted on both ends of the conveying cylinder of the component silo (5) by two deep groove ball bearings (7), and the air cylinder (8) Fixed on the cylinder fixing seat plate of the conveying cylinder, the cylinder (8) pushes the shift fork (9) to drive the sliding coupling (10) and the small bevel gear (11) fixedly connected to the sliding coupling (10) to make The small bevel gear (11) meshes with the central bevel gear (2), and the material in the component bin is transported into the collection box (4) along with the rotation of the conveying screw (6), and the weighing instrument (3) measures the entry When the amount of material reaches the set amount, the cylinder (8) pushes the shift fork (9) to drive the sliding sleeve (10) fixed with the small bevel gear (11) to move backward, so that the small bevel gear (11) and the center The bevel gear (2) is disengaged to cut o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com