Solder paste stirrer housing

A mixer and solder paste technology, applied to mixer accessories, mixers, dissolving, etc., can solve the problems of good effect, time-consuming and laborious, solder paste oxidation, etc., and achieve the effect of simple box structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

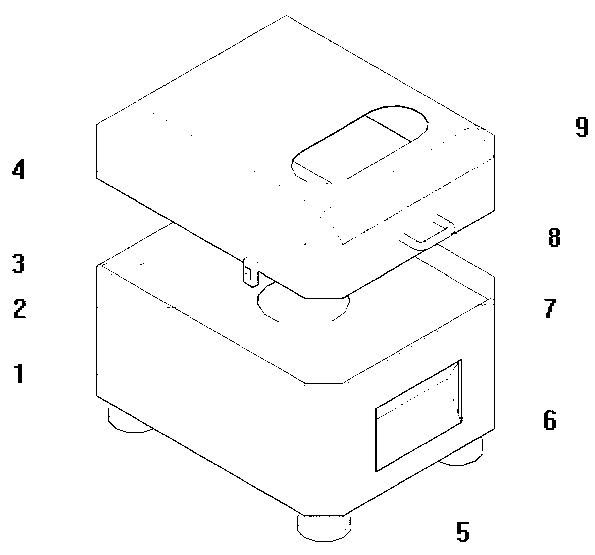

[0010] Referring to the accompanying drawings, a shell of a solder paste mixer includes an adjustable box 1 and a box cover 4 on it. The upper part of the bottom plate 2 of the adjustable box 1 is provided with a partition 7, and the adjustable box 1 The side wall is provided with an operation panel 6, the both sides of the case cover 4 are provided with handles 8 and case locks 3, and the top of the case cover 4 is provided with an observation window 9. The bottom of the adjustable box body 1 is provided with bottom legs 5 .

[0011] The adjustable box body 1 and the box cover 4 on it are made of electro-galvanized sheet through cutting, bending and welding, and the surface is sprayed with plastic, which has good corrosion resistance and scenic spot performance.

[0012] The power structure of the solder paste mixer is installed on the bottom plate 2, the c...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap