Light irradiation apparatus

A technology of light irradiation device and substrate, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high efficiency of difficult substrates, irradiation of ultraviolet rays, etc., and achieve the effect of inhibiting air inflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Hereinafter, embodiments of the light irradiation device of the present invention will be described.

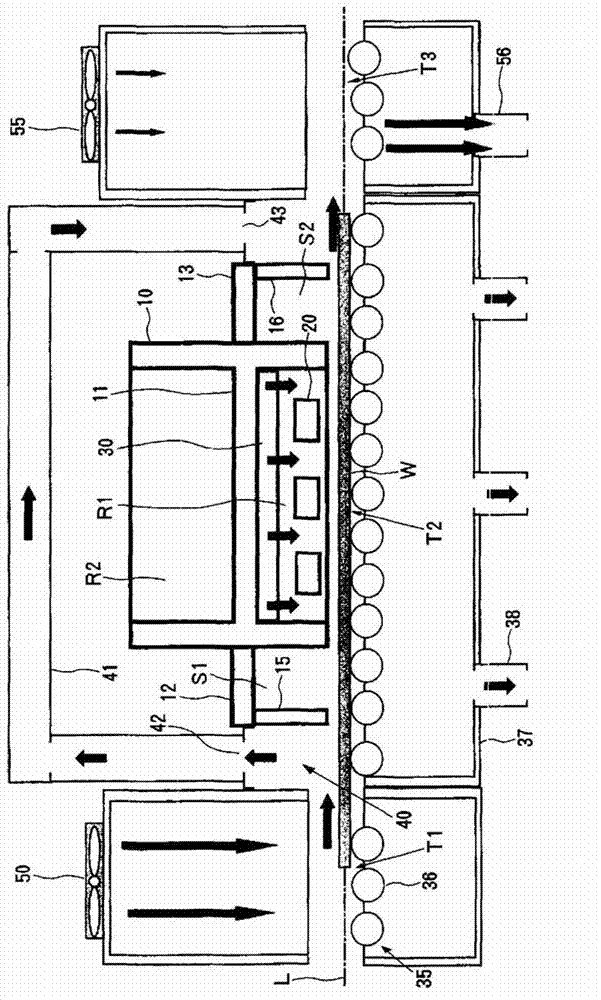

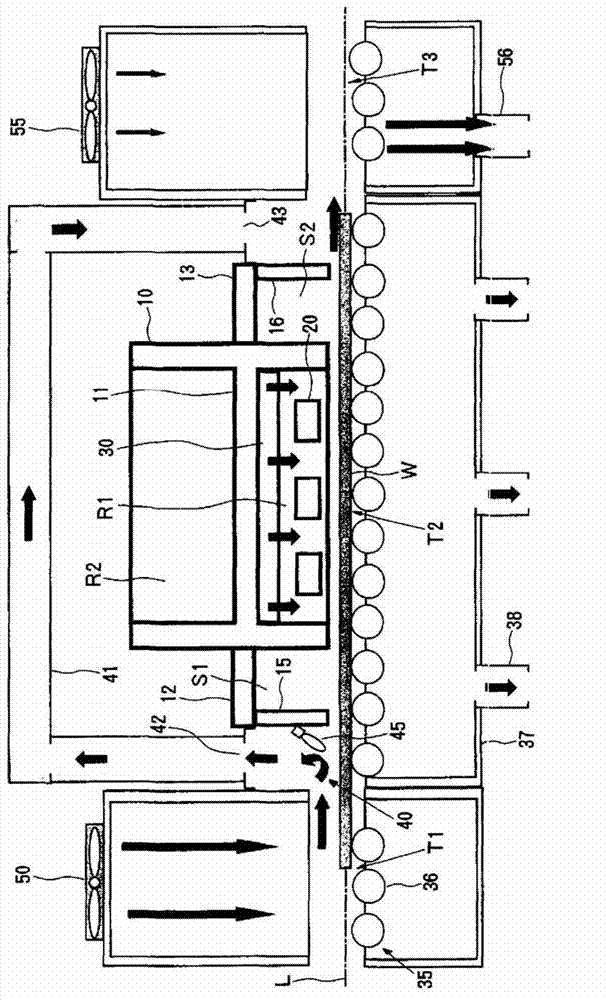

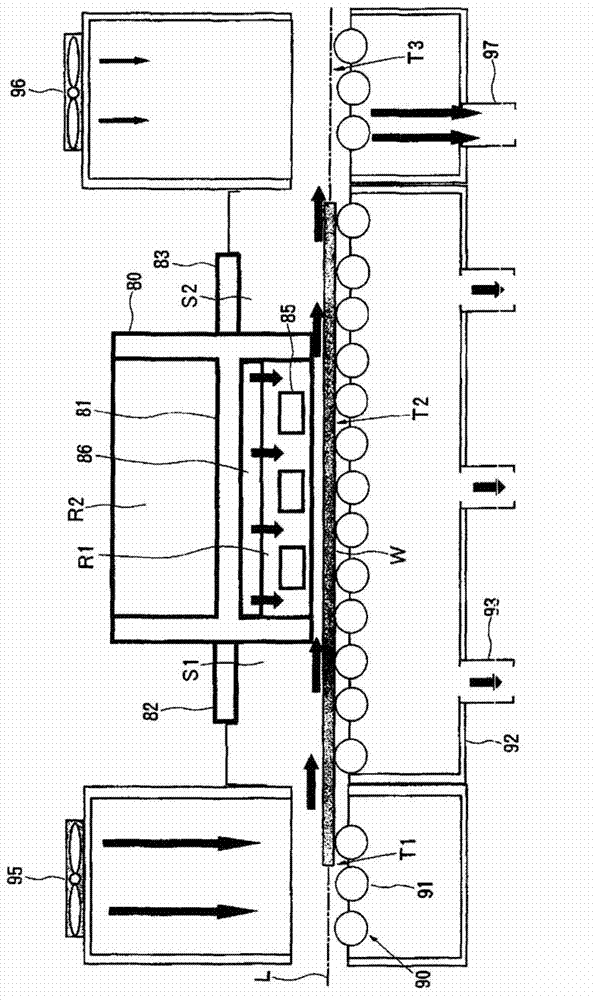

[0061] figure 1 It is an explanatory sectional view showing the structure of an example of the light irradiation device of the present invention. The light irradiation device pairs along the horizontal direction ( figure 1 One side of the substrate W conveyed by the substrate conveying path L extending in the left and right direction ( figure 1 (middle is the upper surface) is irradiated with ultraviolet rays with a wavelength of 200 nm or less, has an opening for light emission formed on the lower surface, and has a substantially rectangular parallelepiped shape. The lamp housing 10 is provided with a partition wall 11 that partitions the interior of the lamp housing 10 up and down, thereby forming a lamp housing room R1 below the housing wall 11 and forming an electrical component housing room R2 above the housing wall 11 .

[0062] In the lamp housing room R1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com