Ceramic tile full-automatic packaging production line

A fully automatic packaging and production line technology, which is applied in the field of tile packaging, can solve the problems of difficulty in further improving production efficiency, inability to realize full automation, and difficulty in increasing output, so as to avoid partial sliding, smooth boxing, and high work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

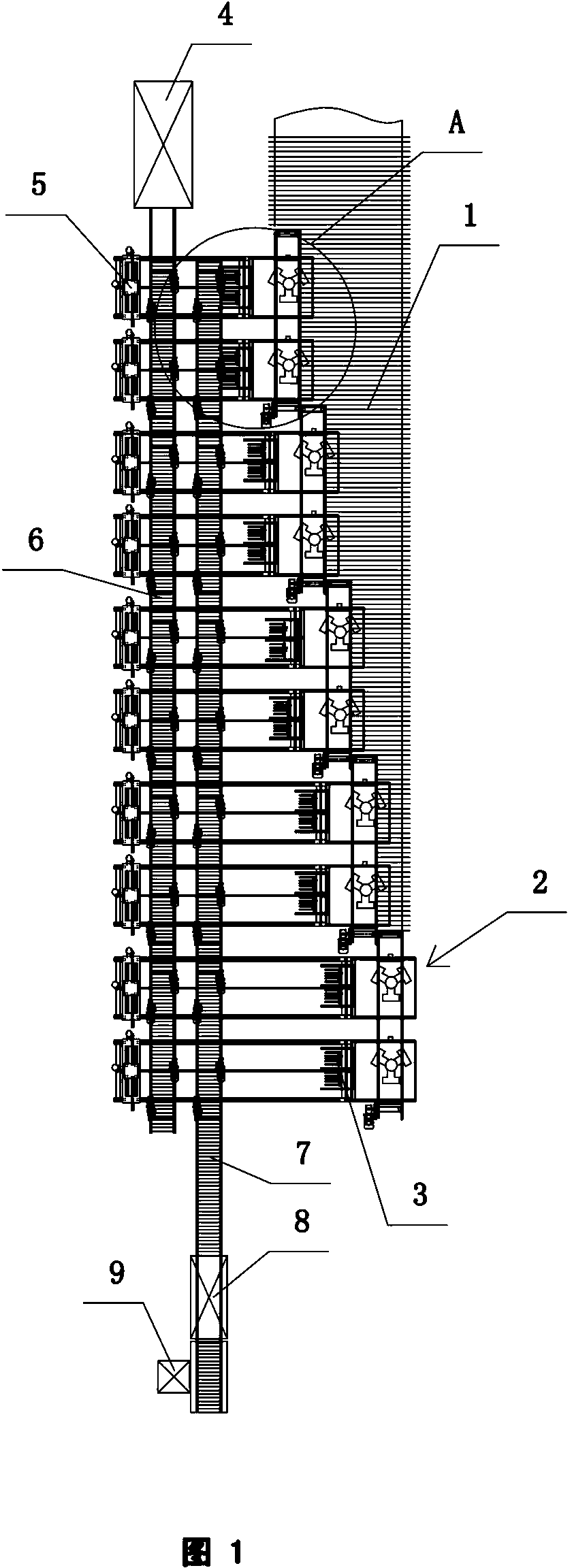

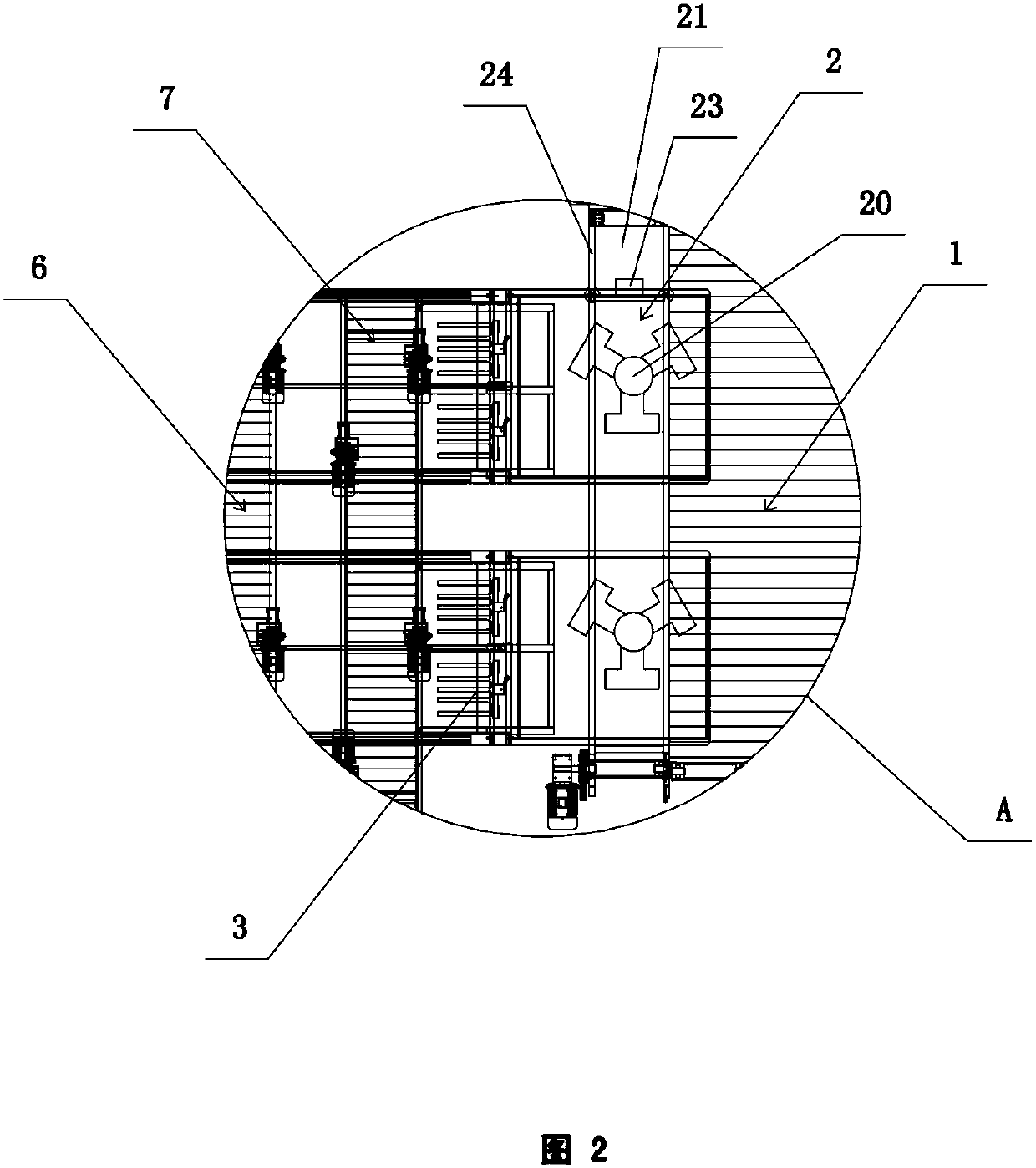

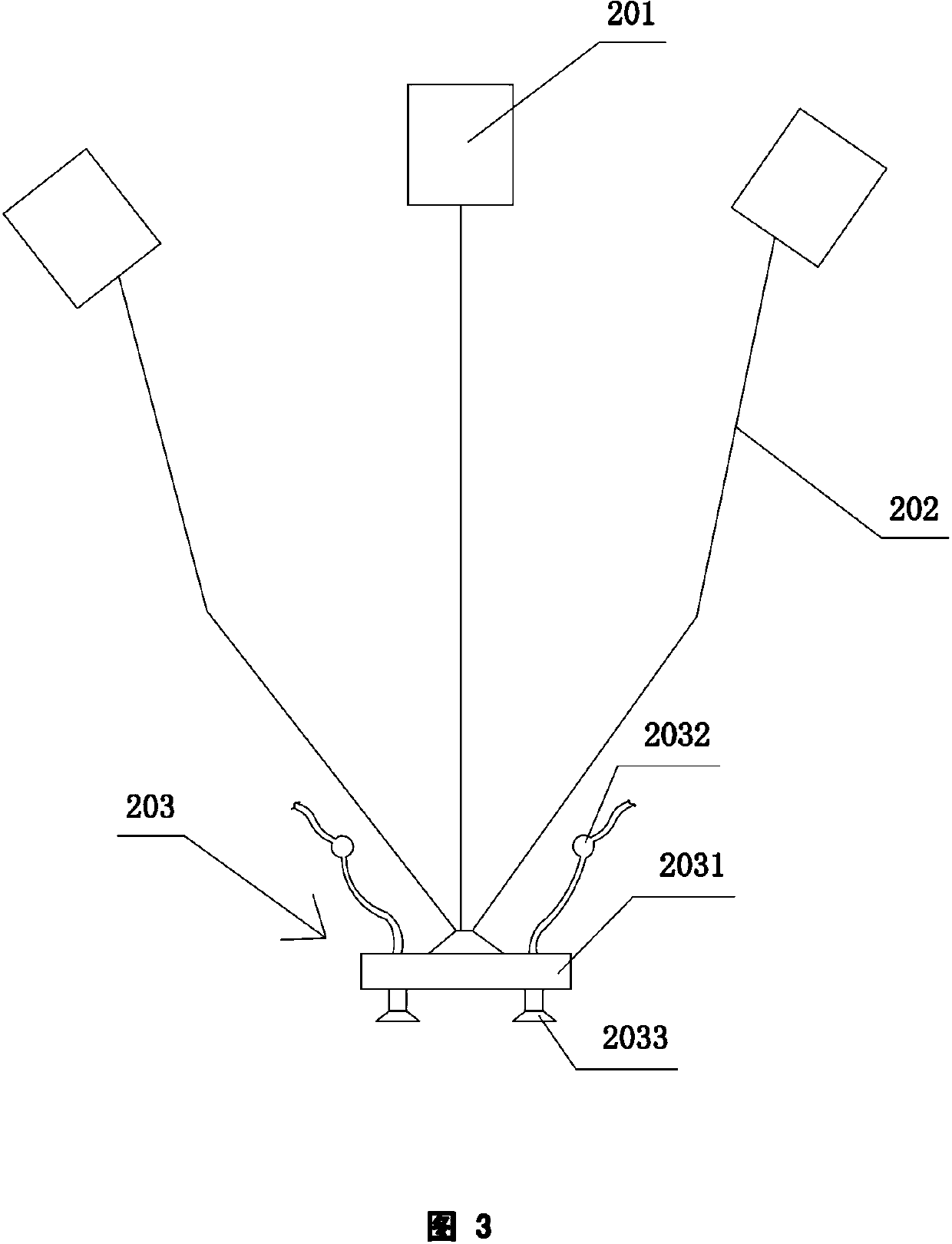

[0033] refer to figure 1 . A fully automatic packaging production line for ceramic tiles, including a furnace rear roller table 1, five sets of tile grabbing mechanisms 2 connected to the furnace rear roller table 1, a tile packing mechanism 3 working with the tile grabbing mechanism 2, and an unpacking machine 4. The first conveying mechanism 6 connected with the unpacking machine 4, the box transporting mechanism 5, the second conveying mechanism 7 carrying away the box of the packed tiles, and the folding mechanism connected with the second conveying mechanism 7. A cover machine 8 and a packing machine 9 for bundling the folded and covered boxes, the roller table 1 behind the furnace, the ceramic tile grabbing mechanism 2, the tile packing mechanism 3, the box unpacking machine 4, and the box body handling mechanism 5 , the first conveying mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com