Modified clamping piece type anchorage device

A clip-type, anchorage technology, applied in the direction of construction, sheet pile walls, foundation structure engineering, etc., can solve the problems of waste of materials, construction obstacles of adjacent buildings, difficult to recycle, etc., to achieve a simple recycling method and convenient recycling of cores materials, easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

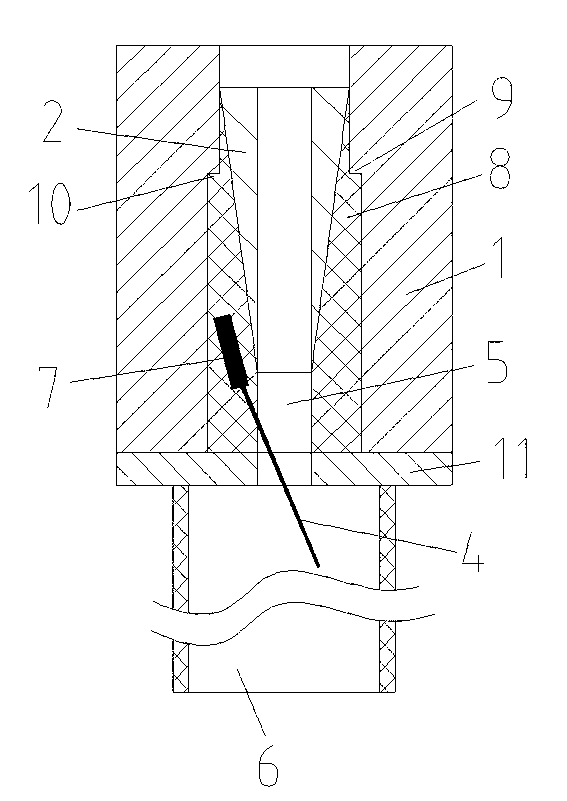

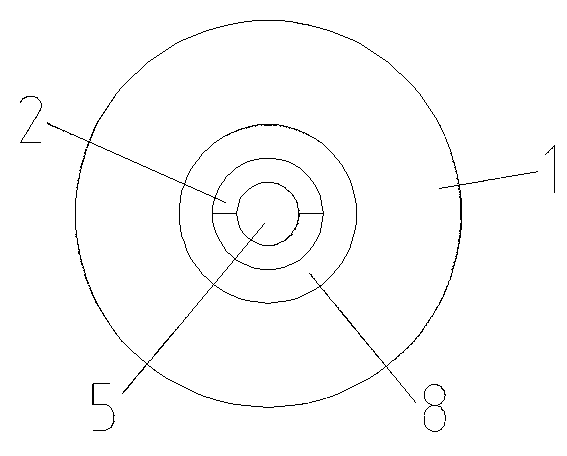

[0016] as attached Figure 1-2 Shown is the improved clip-type anchor of the present invention, which includes an anchor ring assembly 1, a clip assembly 2, a sheath 8, and an isolation sleeve 6; the anchor ring assembly 1 is provided with an anchor hole 5; the The anchor ring assembly 1 includes an anchor ring body (not marked) and a steel plate 11; the steel plate 11 is arranged at the bottom of the anchor ring body; the anchor hole 5 passes through the anchor ring body and the steel plate 11; the anchor ring body The first boss 9 is arranged in the anchor hole on the top; the first boss 9, the steel plate 11, and the anchor hole on the anchor ring body form an enlarged part; the upper part of the sheath 8 is provided with a second boss, When the sheath 8 is inserted into the enlarged part, the bottom of the sheath 8 is arranged on the steel plate 11, and the second boss 10 cooperate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com