Wireless remote control walking-type underwater bump-cutter machine operational method

A technology of wireless remote control and operation method, which is used in river remediation, mechanically driven excavators/dredgers, etc., to achieve the effects of good quality, accurate horizontal and elevation positioning, and long operating time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

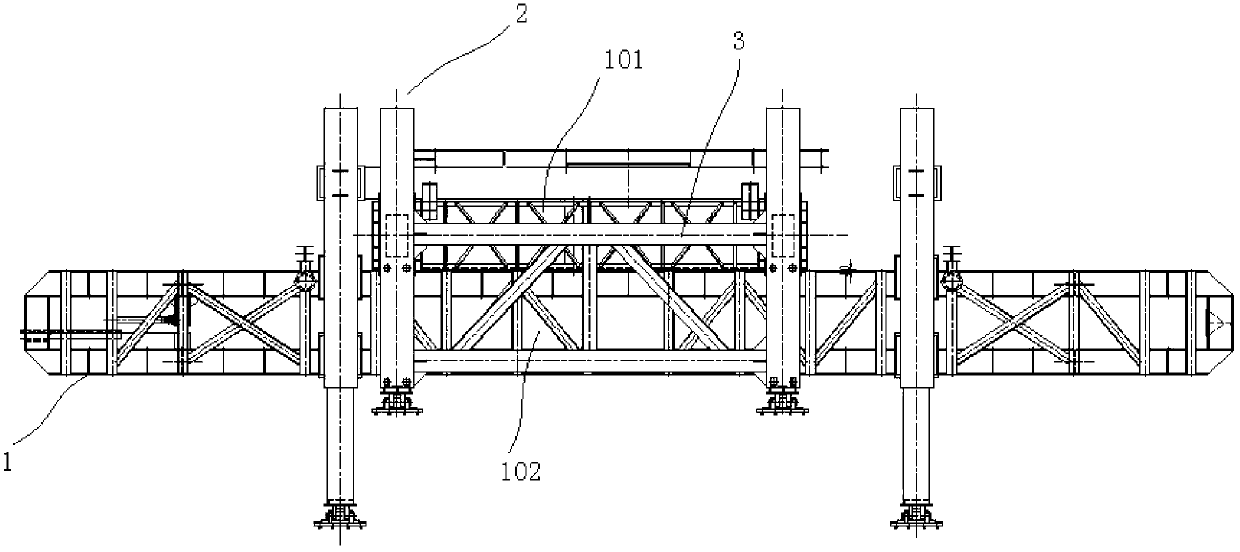

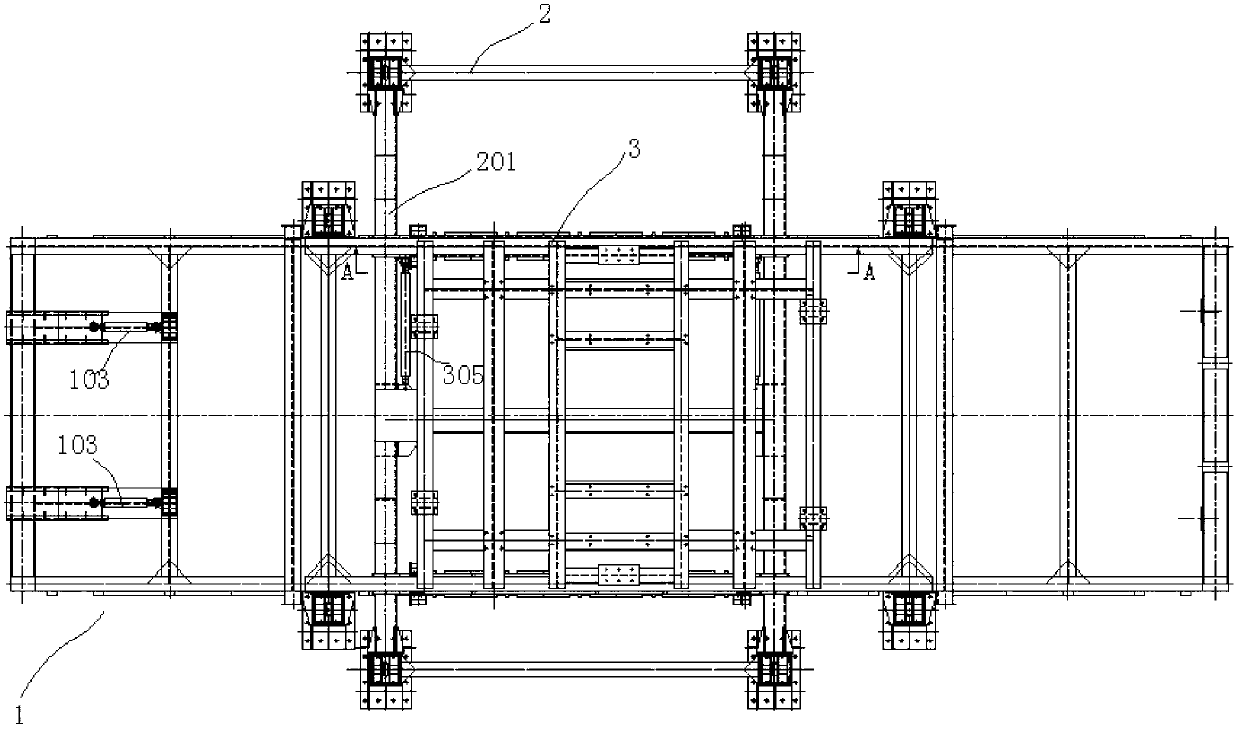

[0052] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

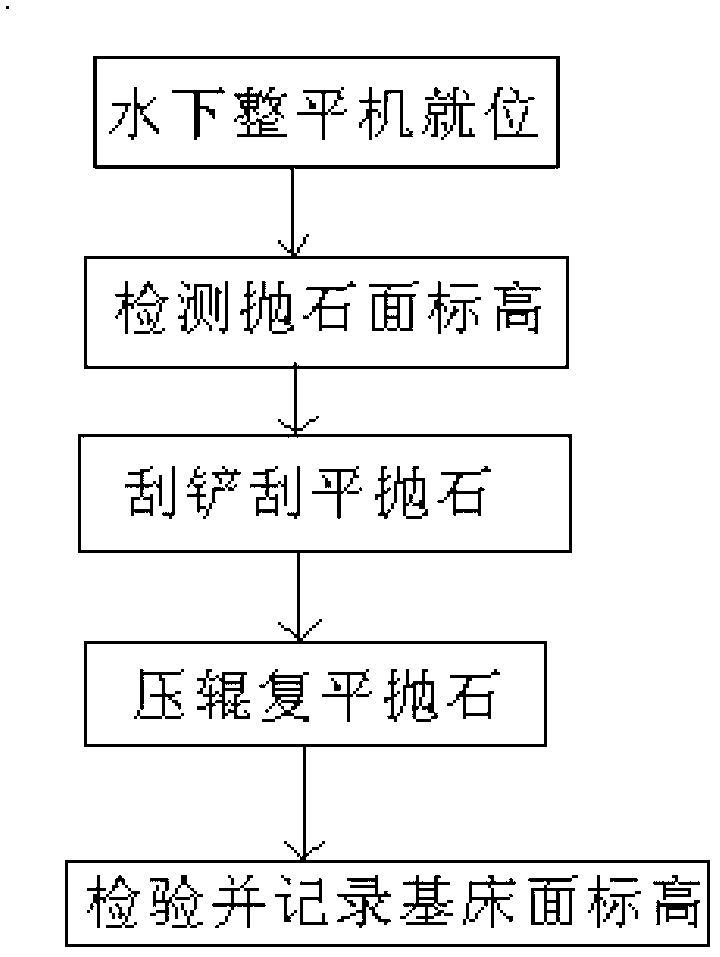

[0053] refer to figure 1 , the operation method of the wireless remote control walking underwater leveling machine, including:

[0054] Step 1) Underwater screed in place

[0055] When the underwater leveling machine is put into the water for the first time, the first action is to stand firm, and then adjust the support cylinders respectively according to the signals sent by the two underwater level sensors. This is the leveling process, and then according to the Plane position display to perform actions such as horizontal stepping, vertical stepping or deviation correction;

[0056] Step 2) Detect the elevation of the riprap

[0057] Start the mobile trolley, and detect the elevation of the riprap surface according to the data sent by the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com