A plastic hollow water irrigation movable fence

A hollow and water-filled technology, applied to fences, building types, buildings, etc., can solve the problems of raw material storage, inconvenient transportation, no universal standard for fences, and waste that cannot be reused, etc., to achieve low turnover cost and flexible weight reduction The effect of convenient, convenient and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

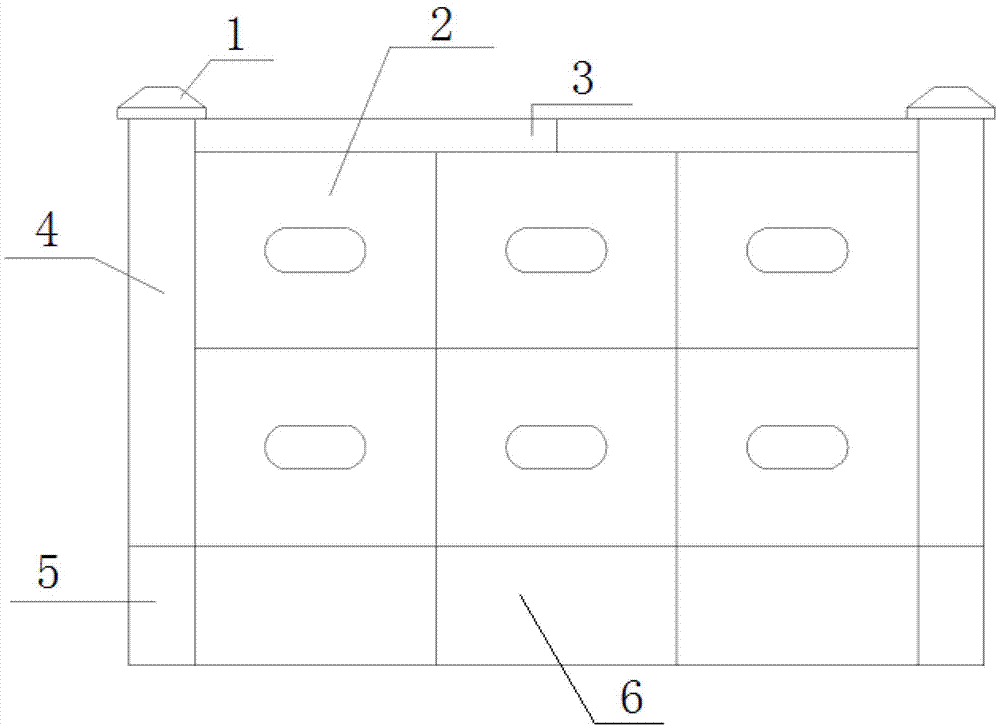

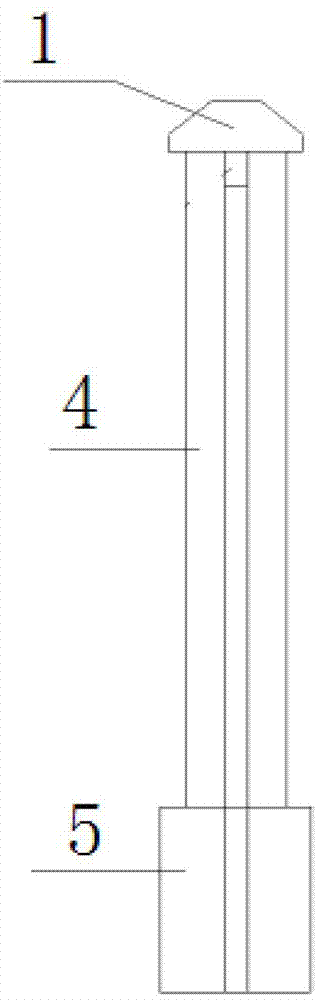

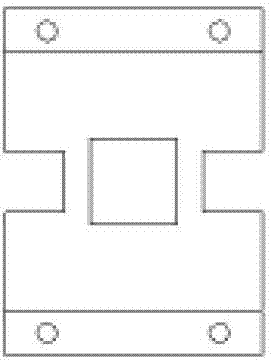

[0025] Such as Figure 1-7 Shown, a kind of plastic hollow pouring movable fence, comprises wall body and wall stud, described wall body comprises wall base 6, wall body 2 and wall cap 3 installed in sequence from bottom to top, described wall stud includes Column base 5, column body 4 and column cap 1 installed in sequence from bottom to top, several wall bases 6 are fixed between the two column bases 5, and the same number of wall bases 6 are installed on each wall base 6

[0026] The wall body 2 is fixed with a wall cap 3 on the wall body 2.

[0027] The column cap 1 is connected and fixed to the upper end of the column body 4 through a concave-convex structure.

[0028] The lower end of the column body 4 and the column base 5 are fixed through the fitting connection of the mounting holes, angle steel and bolts.

[0029] The cross-section of the wall base 6 is trapezoidal, and the wall bases 6 are embedded and connected by a concave-convex structure and fixed through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com