Opening type roasting fire way pulling brick and method of fire hole arrangement

An arrangement method and an open technology, applied in the direction of furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as easy deformation and influence on heat transfer uniformity, so as to prolong service life, improve gas flow and extend flame length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

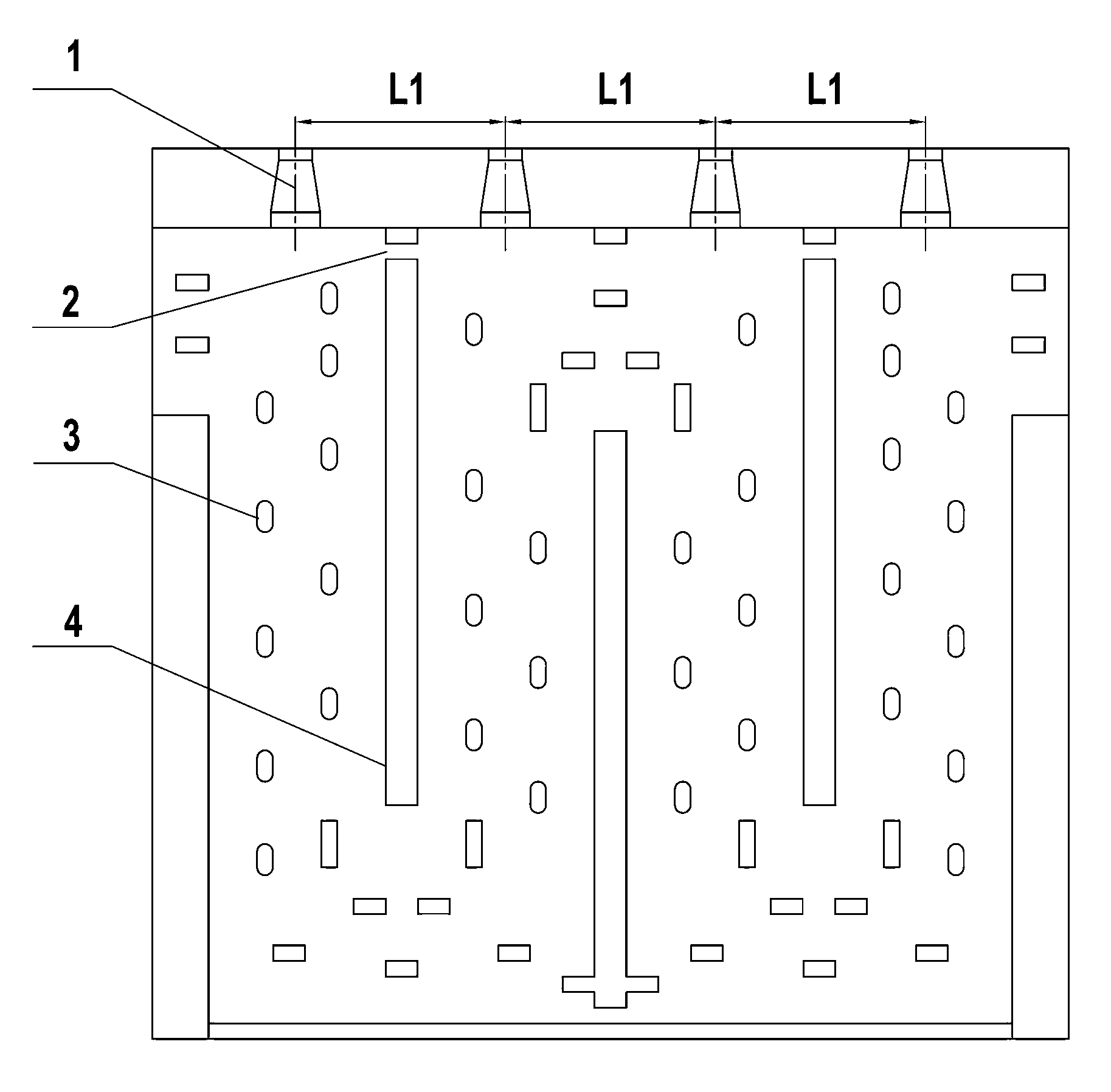

[0015] As shown in the figure, the open-type roasting furnace fire path brick and fire hole layout method of the present invention, the two adjacent fire path bricks 3 in the roasting furnace adopt a staggered arrangement in the height direction, so that the adjacent two fire path bricks The height is not on a straight line, which makes the air flow more uniform when flowing in the height direction, and changes the phenomenon of smoke stagnation in the backflow area of the traditional straight line arrangement.

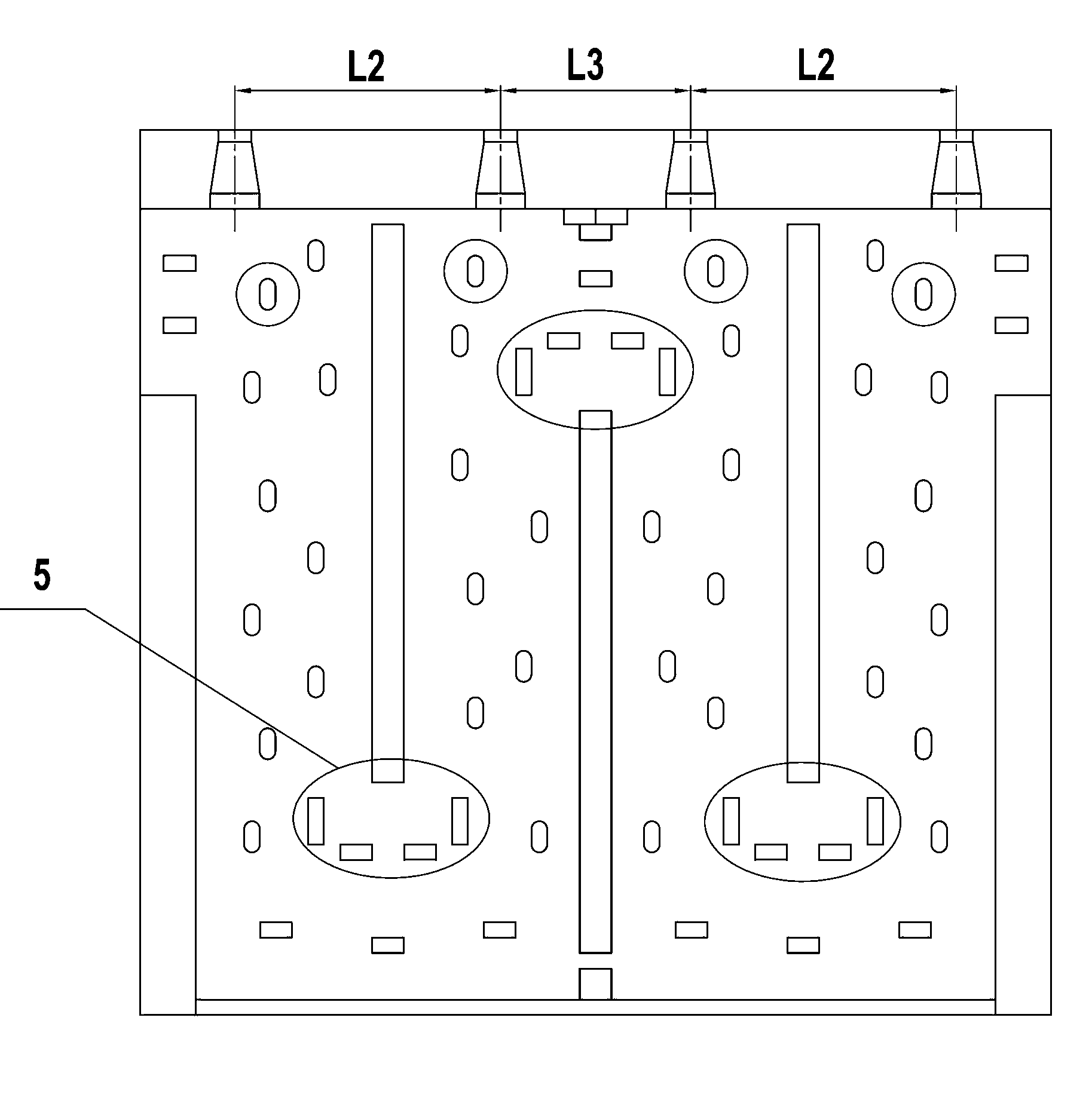

[0016] At each turn of the "W" flow form of the fire channel, a U-shaped 5 or inverted U-shaped diversion structure is formed by four pull bricks, so that the airflow flows to the back flow area of the partition wall 4 after turning, ensuring that the smoke is kept in the fire The uniformity of the flow in the channel, while ensuring the uniformity of heat tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com