Electrolysis system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

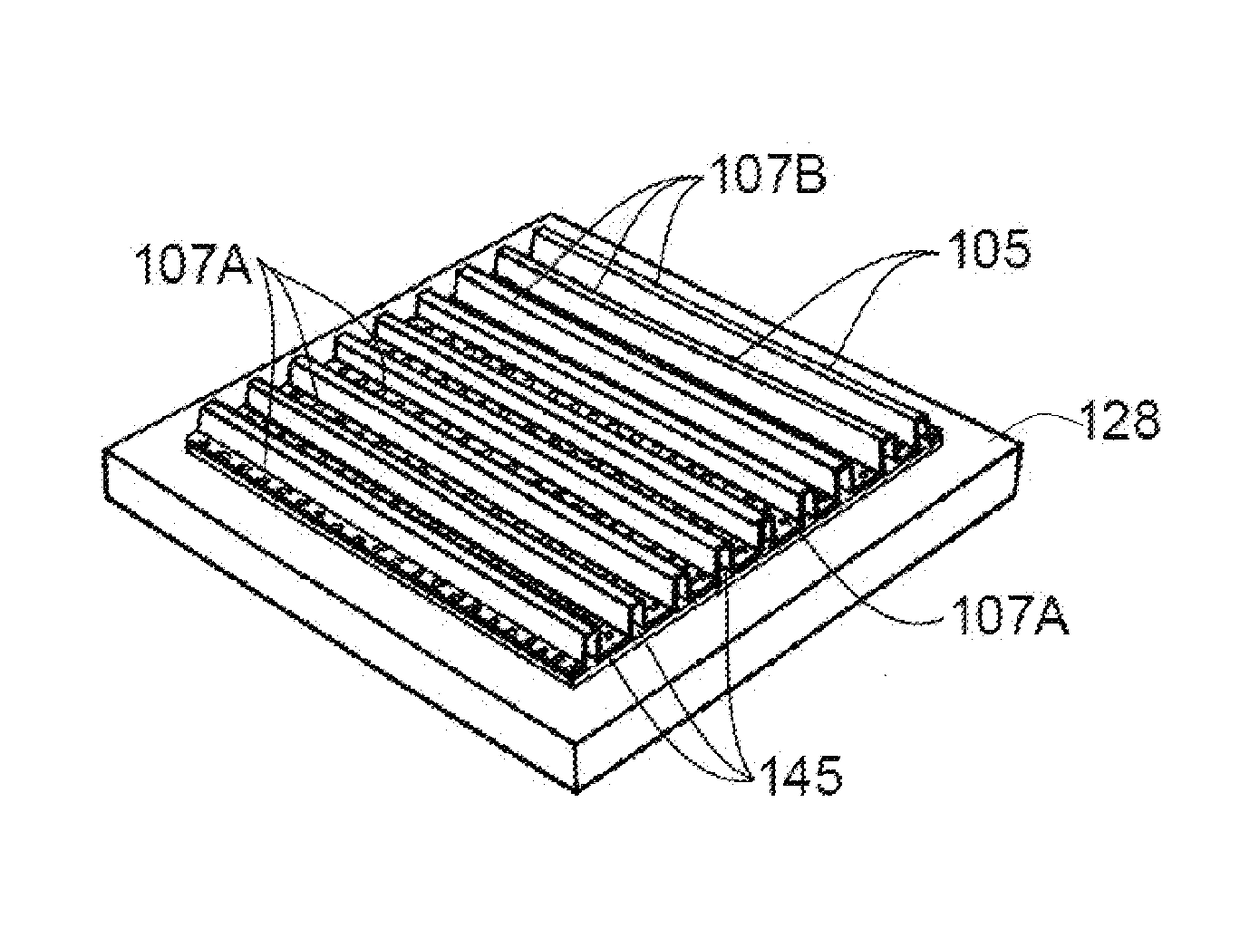

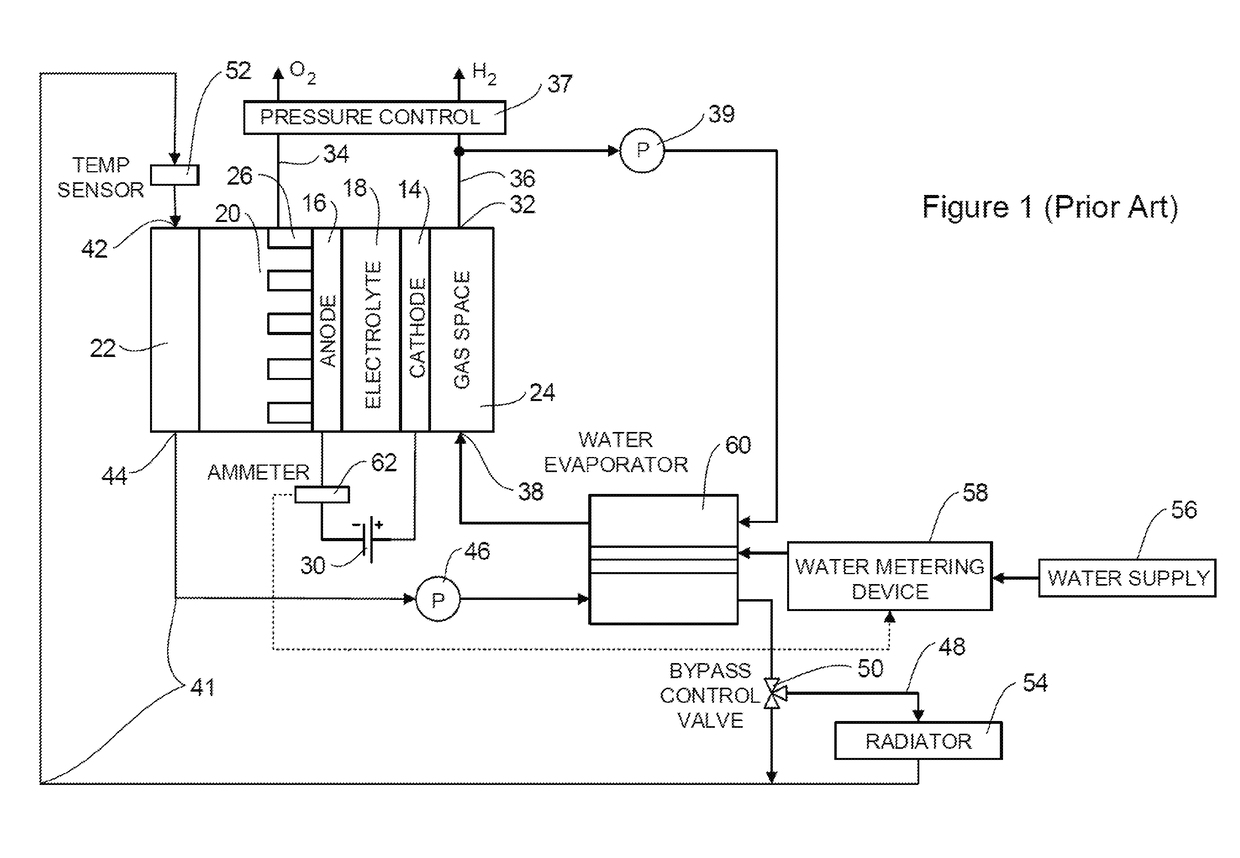

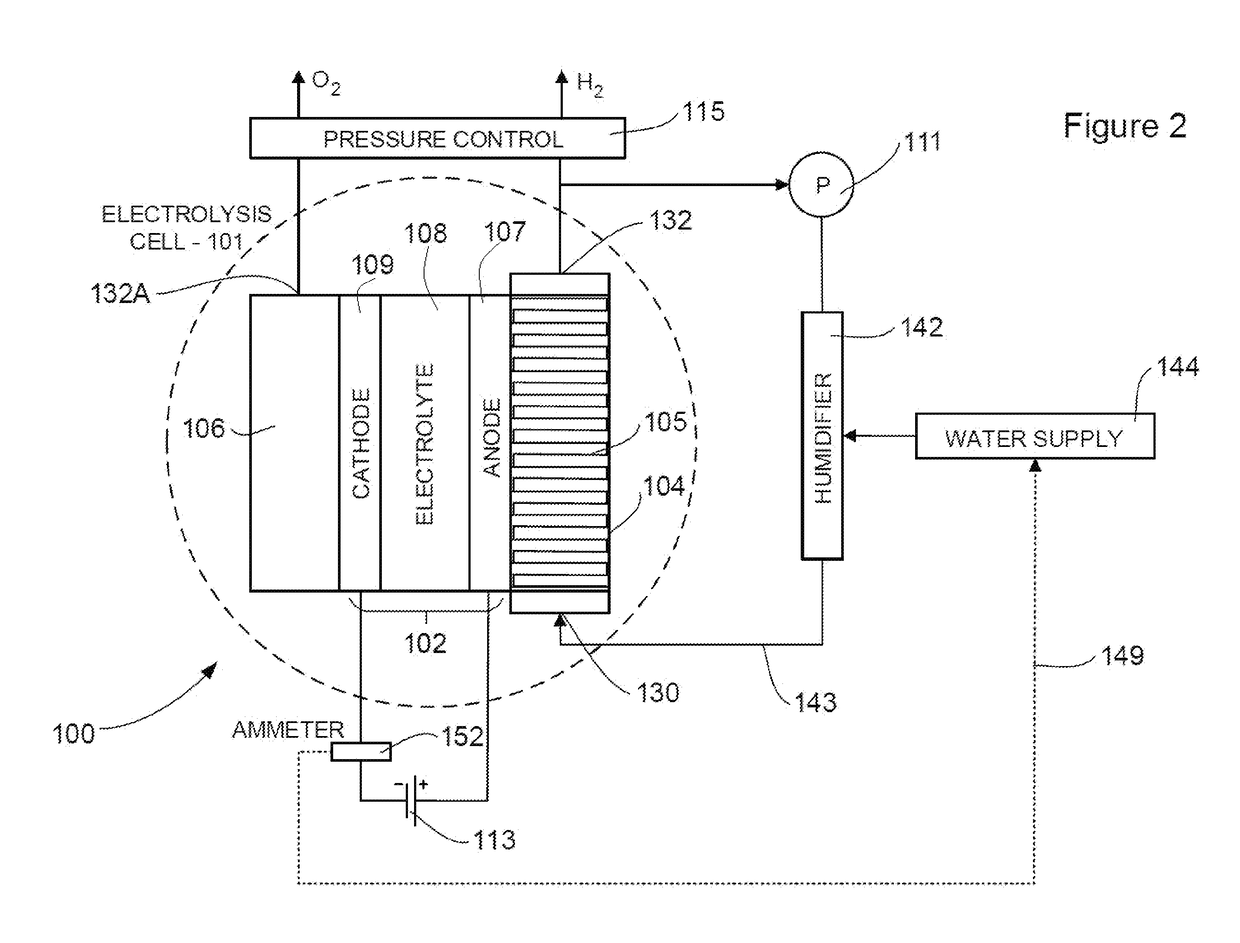

[0045]The present invention provides an electrolysis cell which produced hydrogen and oxygen product gases from a water supply. The electrolysis cell of the present invention generally includes a membrane electrode assembly containing an anode, a cathode and electrolyte therebetween.

[0046]One development provided by the present invention is the use of a heat transfer arrangement that facilitates efficient heat transfer between the membrane electrode assembly and either the oxygen gas or hydrogen product gas produced by the membrane electrode assembly. The heat transfer arrangement of the present invention is housed in an electrode gas chamber on the non-electrolyte side of the anode or cathode depending on the desired configuration of the electrolysis cell. The heat transfer arrangement is physically connected to the respective anode or cathode. Product oxygen or hydrogen product gas circulates through electrode gas chamber over the heat transfer arrangement to remove heat from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com